Constant tension control method for paper making blanket needling machine

A papermaking felt, constant control technology, applied in textiles and papermaking, looms, textiles, etc., can solve the problems of large periodic tension error, uneven gap, waste papermaking felt, etc., to achieve constant tension and uniform weft yarn gap effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

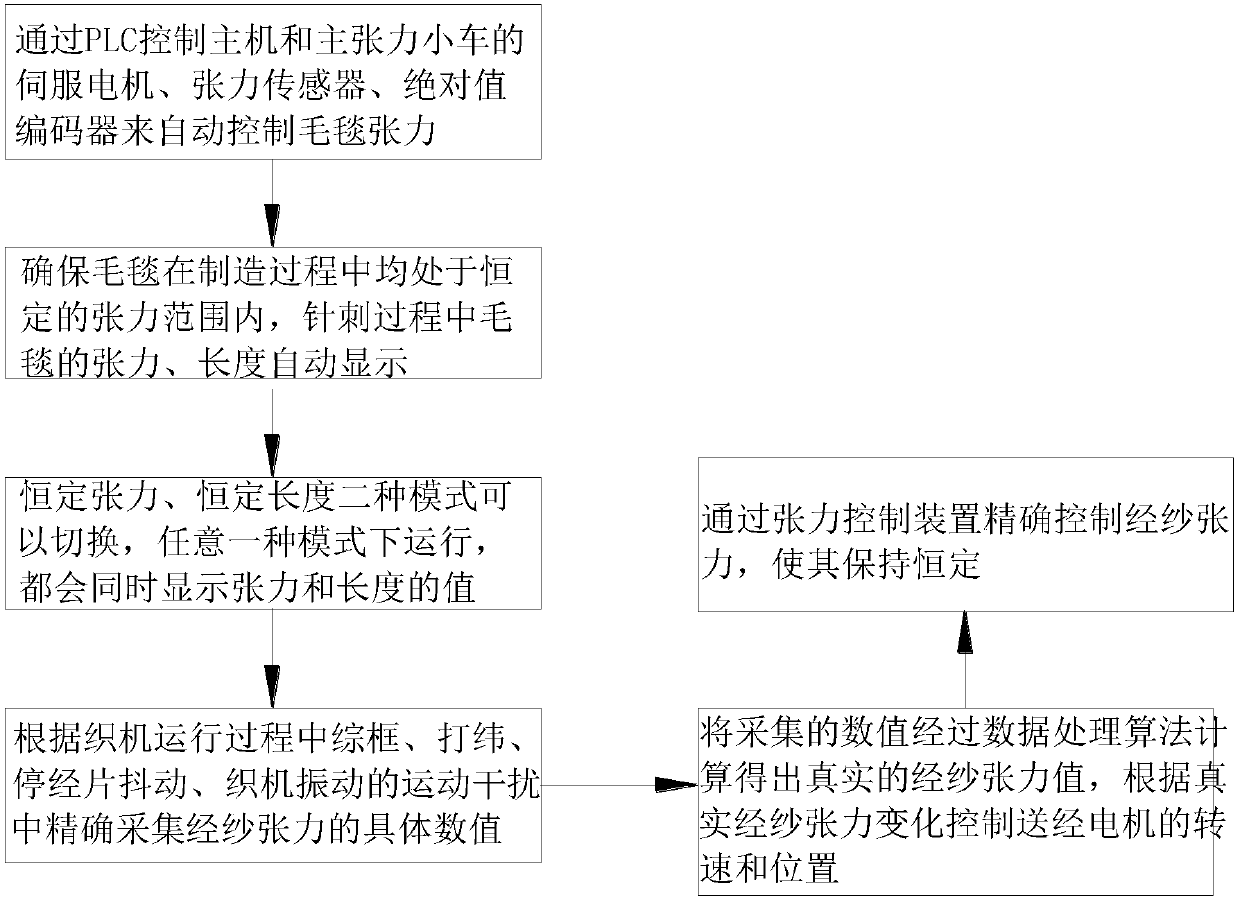

[0018] like figure 1 As shown in the figure, a constant tension control method for a papermaking felt needle punching machine, the method steps are: (1) Control the servo motor, tension sensor and absolute value encoder of the main engine and the tension trolley through PLC to automatically control the felt tension; ( 2) Make sure that the felt is in a constant tension range during the manufacturing process, and the tension and length of the felt during the needle punching process are automatically displayed; (3) The two modes of constant tension and constant length can be switched. Simultaneously display the values of tension and length; (4) Accurately collect the specific value of warp tension according to the movement interference of heald frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com