Quick stamping die

A technology of stamping dies and molds, which is applied in the field of rapid stamping dies and can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

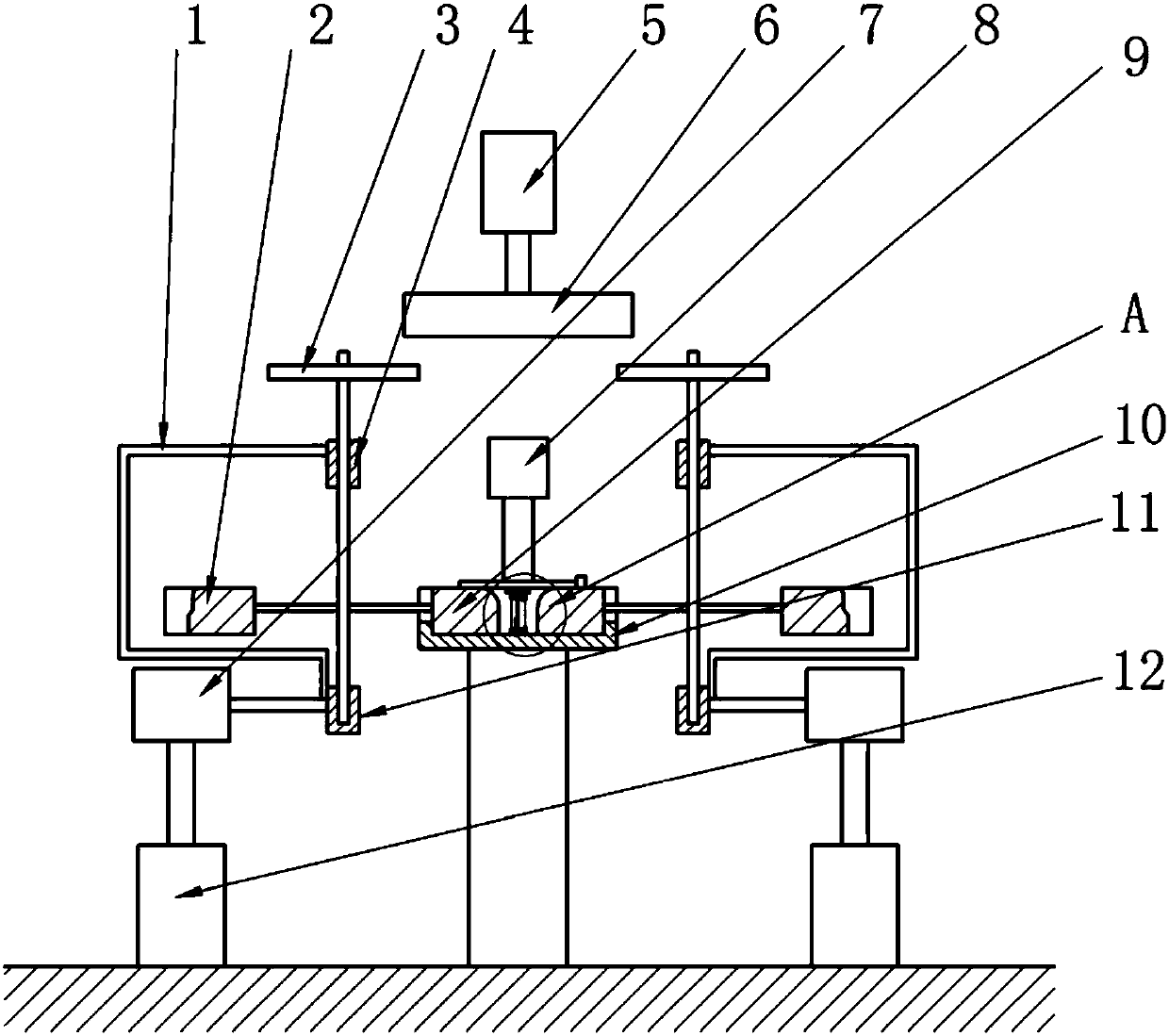

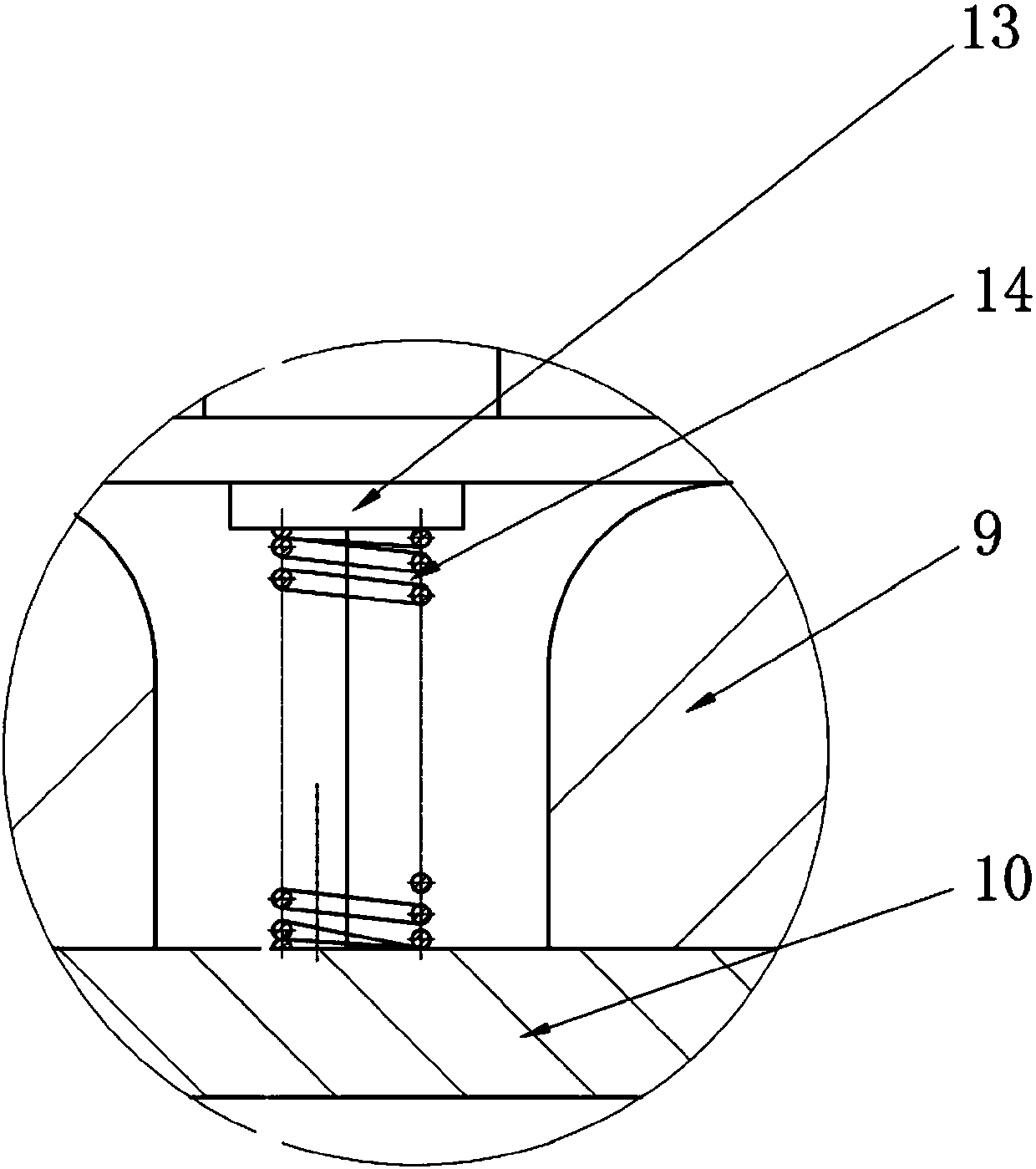

[0018] The reference signs in the drawings of the description include: the third connecting rod 1, the second half mold 2, the driven gear 3, the balance sleeve 4, the rotating motor 5, the driving gear 6, the push cylinder 7, the stamping cylinder 8, the first half Die 9, stamping platform 10, fixed sleeve 11, lifting cylinder 12, stripping plate 13, stripping spring 14.

[0019] Embodiment: the rapid stamping die in this scheme, as figure 1 and figure 2 As shown, it includes a mold lifting mechanism, a rotating mechanism and a stamping mechanism. The stamping mechanism includes a frame and a stamping cylinder 8. A vertical stamping platform 10 is fixedly connected to the frame. The free end of the stripping spring 14 is fixedly connected with the stripping plate 13, and the stripping plate 13 is located directly below the output end of the stamping cylinder 8, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap