Automatic clipping machine for pipe fitting joint sprue

A technology for shearing machines and pipe fittings, which is applied in the field of automatic shearing machines for pipe joint gates, can solve the problems of low shearing operation efficiency and achieve high gate shearing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the drawings.

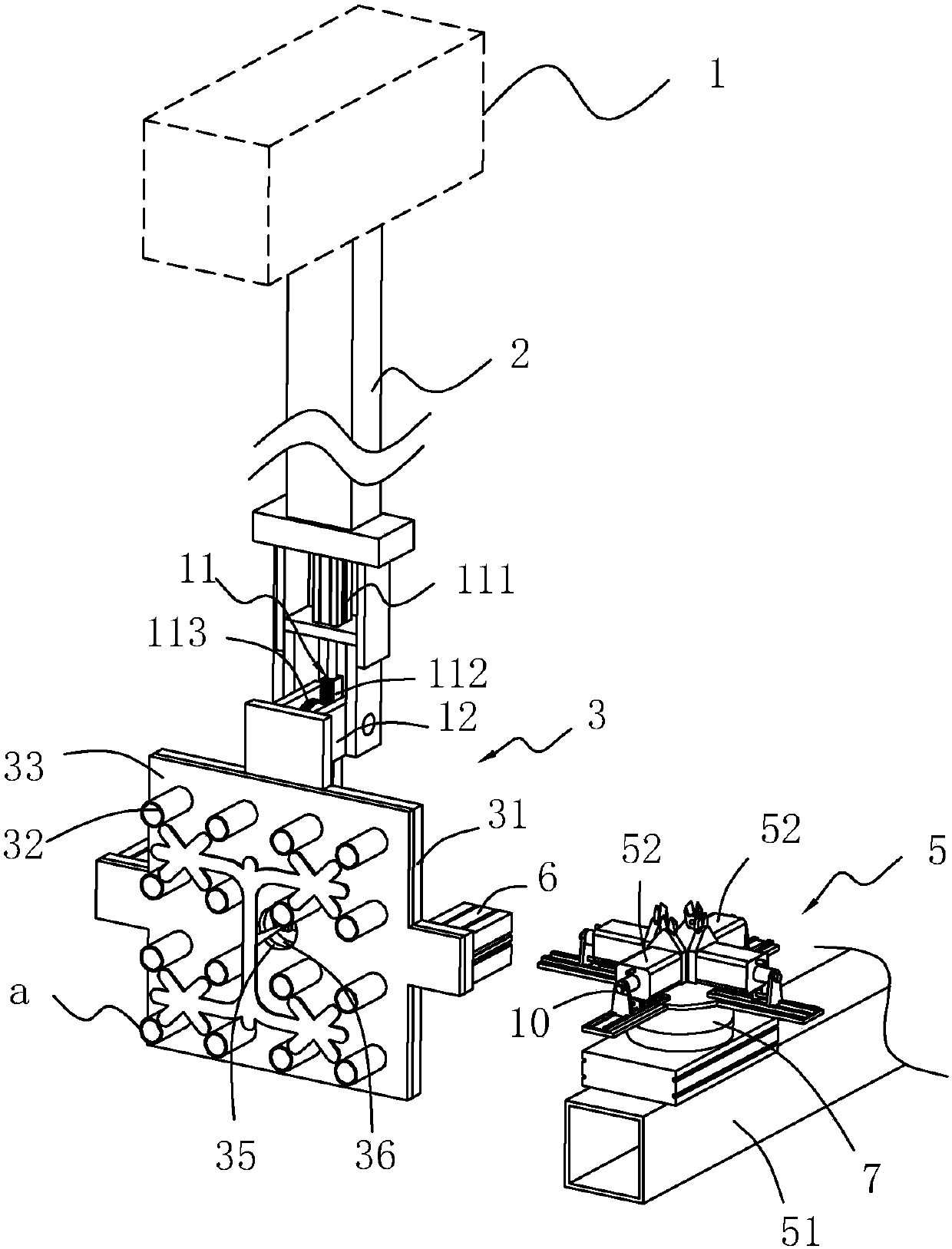

[0037] An automatic cutting machine for the sprue of pipe fittings, see figure 2 , Including a driving source 1, a moving arm 2, the driving source 1 is installed on an external beam, the moving arm 2 is arranged vertically downward, and the driving source 1 can drive the moving arm 2 to move back and forth, up and down, and left and right.

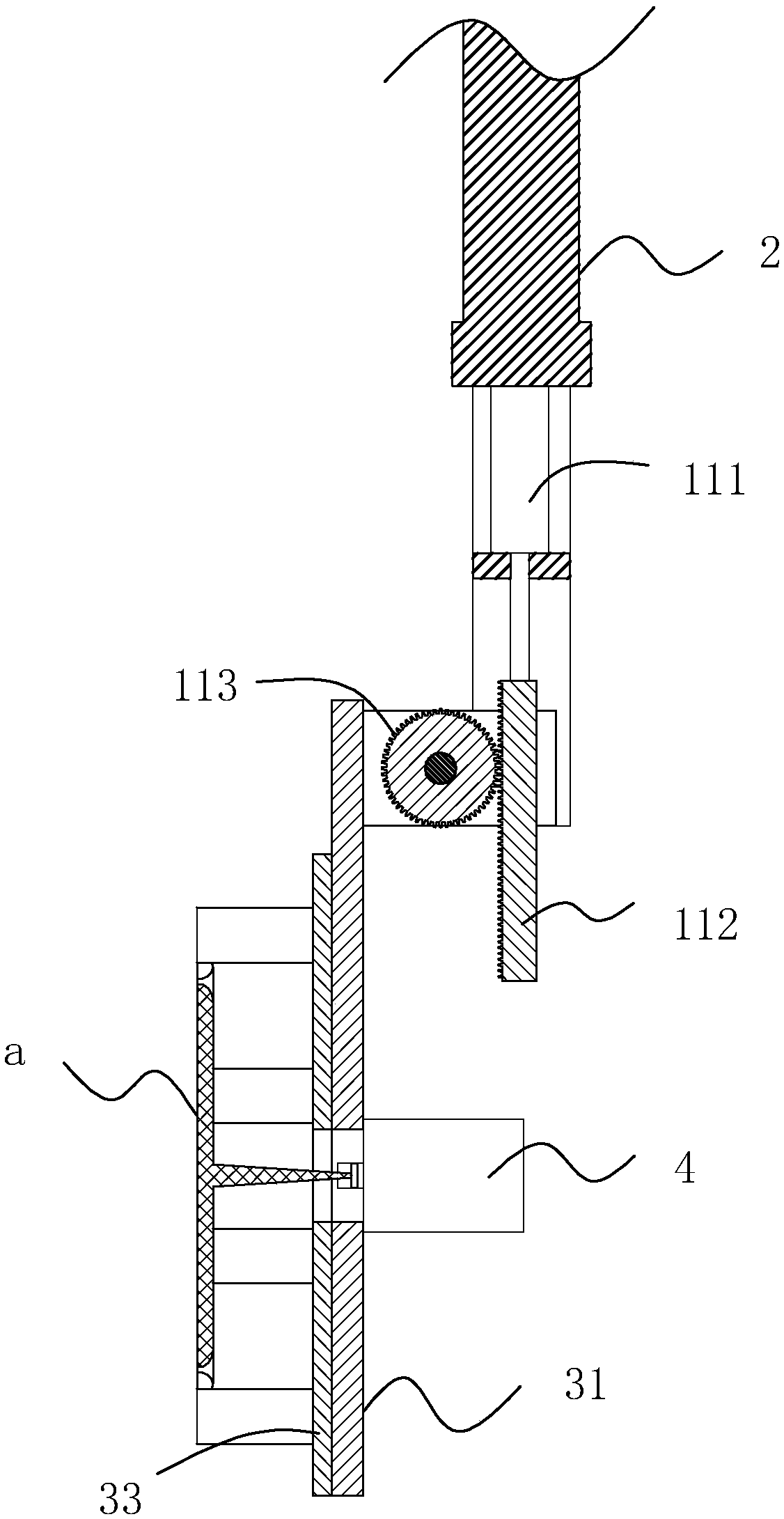

[0038] See figure 2 as well as image 3 , The lower end of the mobile arm 2 is provided with a flip arm 12 and a flip drive 11, the flip arm 12 is hinged to the lower end of the mobile arm 2, the hinge shaft is fixedly connected to the flip arm 12, the hinge between the flip arm 12 and the mobile arm 2 The axis of the shaft is arranged horizontally. The turning drive unit 11 includes a turning cylinder 111 mounted on the moving arm 2. The telescopic direction of the turning cylinder 111 is vertical. The telescopic end of the turning cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com