Bonding device and control method of bonding device

A technology of bonding and control, which is applied in the directions of transportation and packaging, sending objects, thin material processing, etc., which can solve the problems that the adhesive cannot be discharged from the discharge port, and the adhesive is insufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

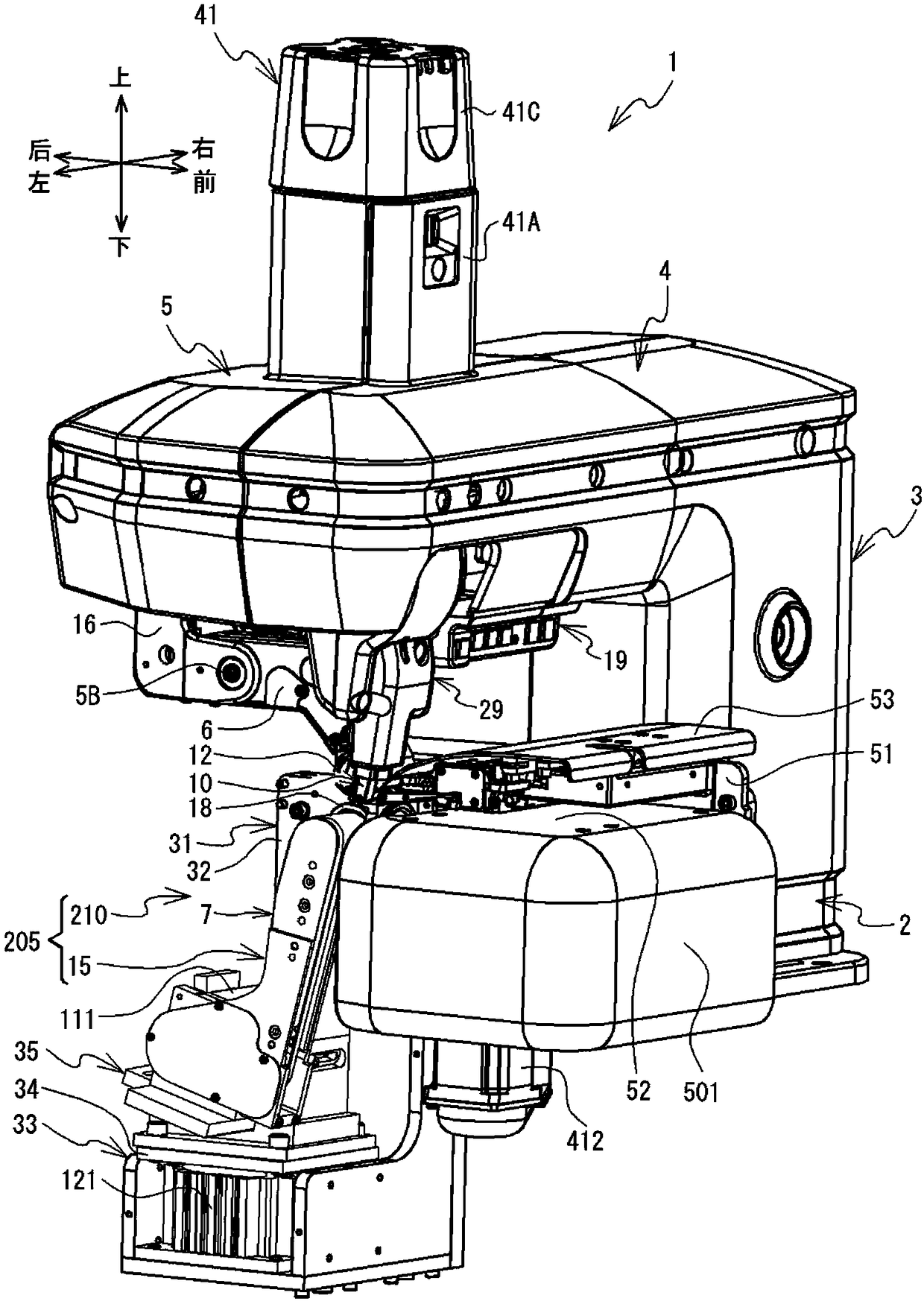

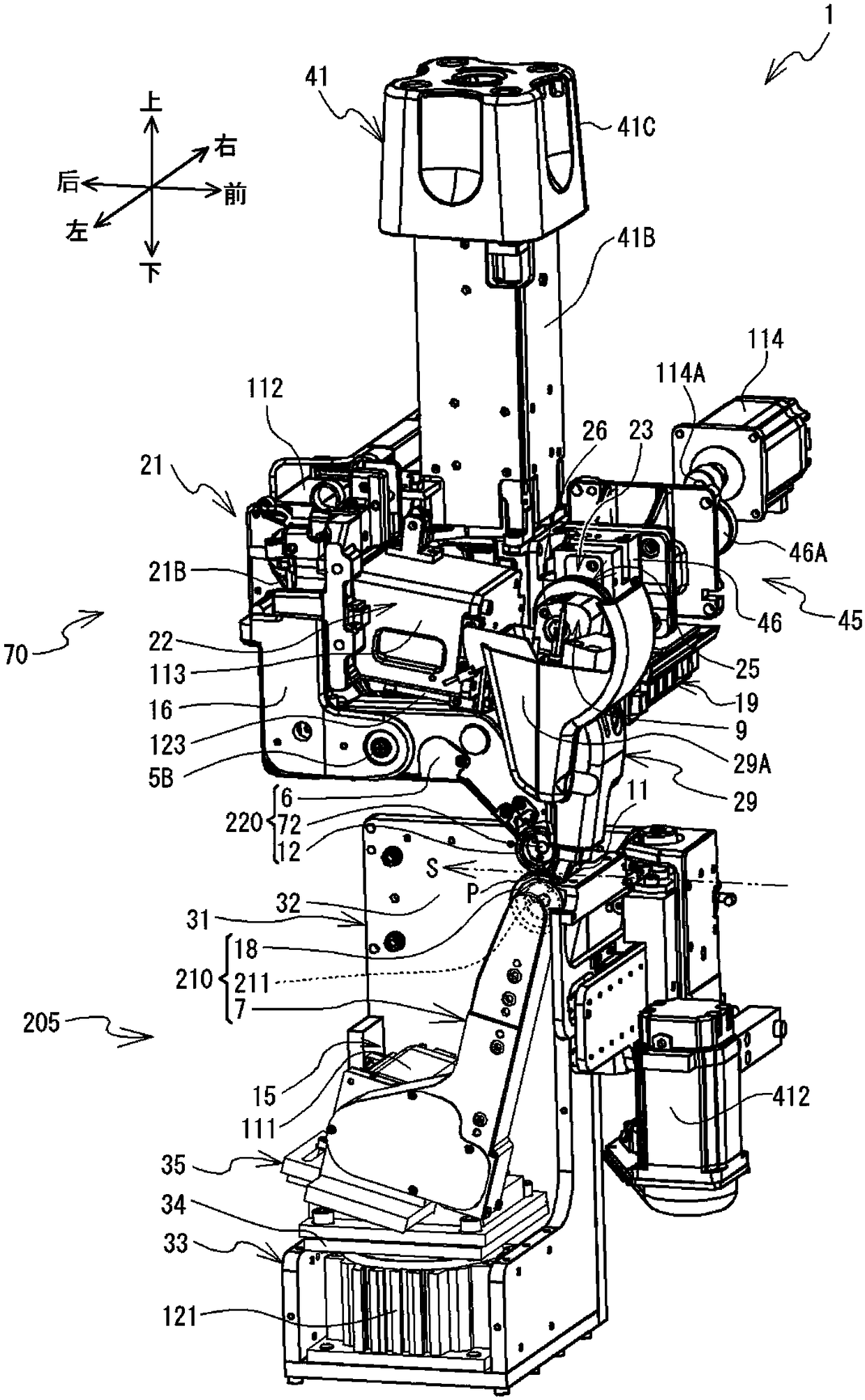

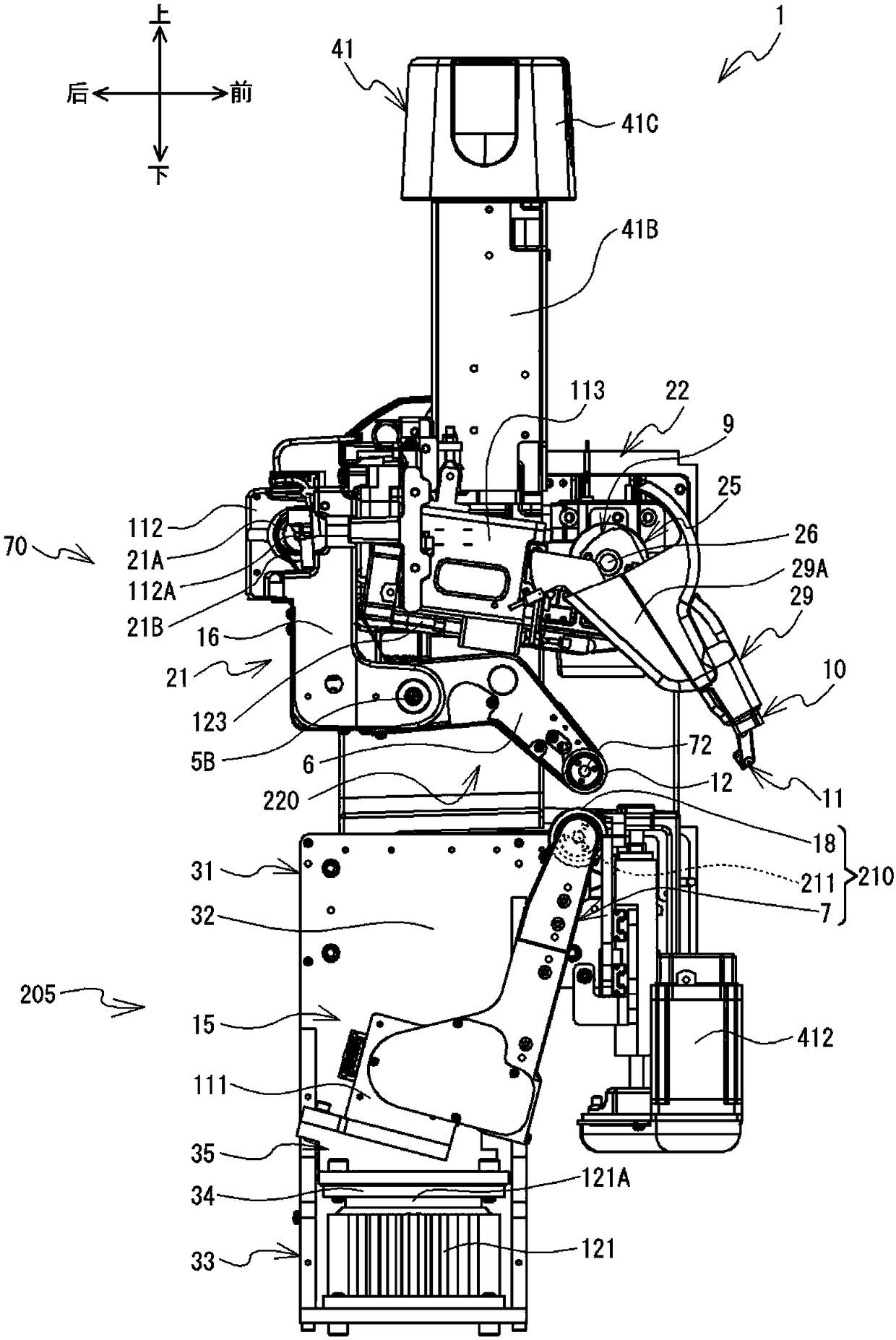

[0034] Embodiments of the present invention will be described. The following description uses left and right, front and rear, and up and down indicated by arrows in the drawings. The bonding apparatus 1 is capable of bonding two objects to be bonded using the adhesive Z. The objects to be bonded are flexible sheets, for example, the lower cloth C1 and the upper cloth C2.

[0035] refer to Figure 1 to Figure 11 , the mechanical structure of the bonding apparatus 1 will be described. Such as Figure 1 ~ Figure 3 As shown, the bonding device 1 has a base part 2 , a pillar part 3 , an arm part 4 and a head part 5 . The base part 2 is in the shape of a cuboid, and is fixed on the workbench. The pillar part 3 has a columnar shape and extends upward from the upper surface of the base part 2 . The arm portion 4 extends leftward from the upper end portion of the pillar portion 3 . The head portion 5 protrudes leftward from the left end portion of the arm portion 4 . The stand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com