clutch device

A clutch device and clutch technology, applied in the direction of clutches, friction clutches, mechanically driven clutches, etc., can solve problems such as short engagement-and-disengagement strokes, short axial displacement length, controllability and adjustability of clutch devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

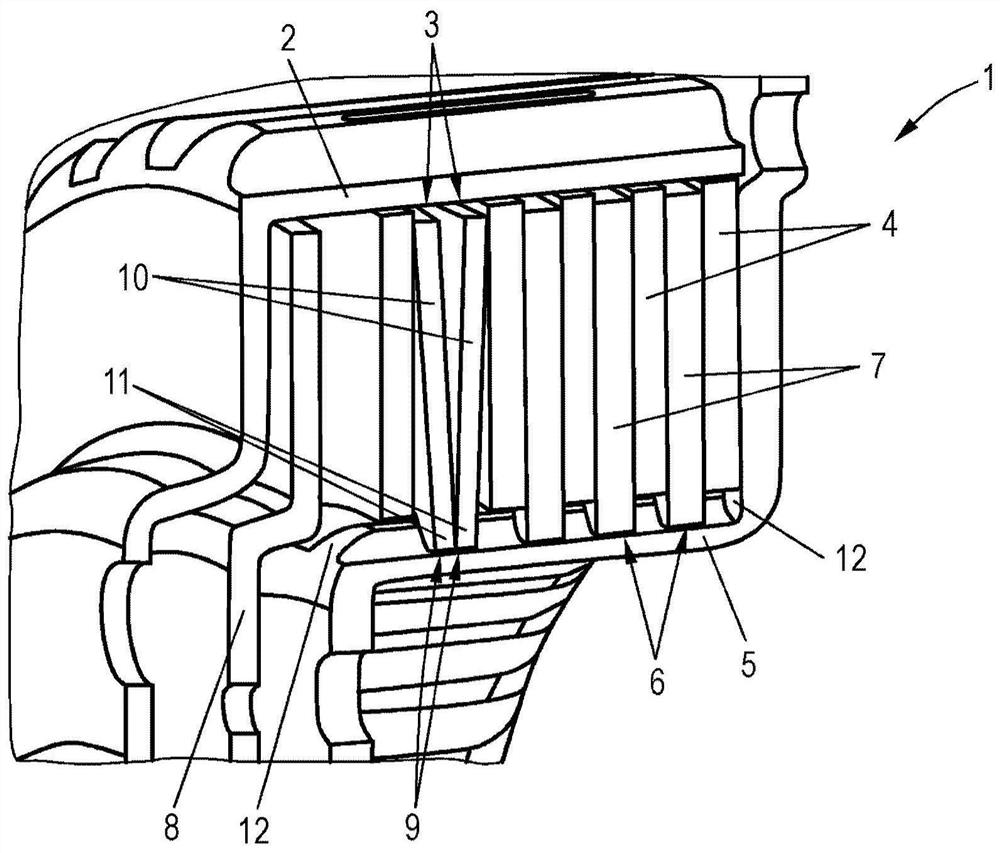

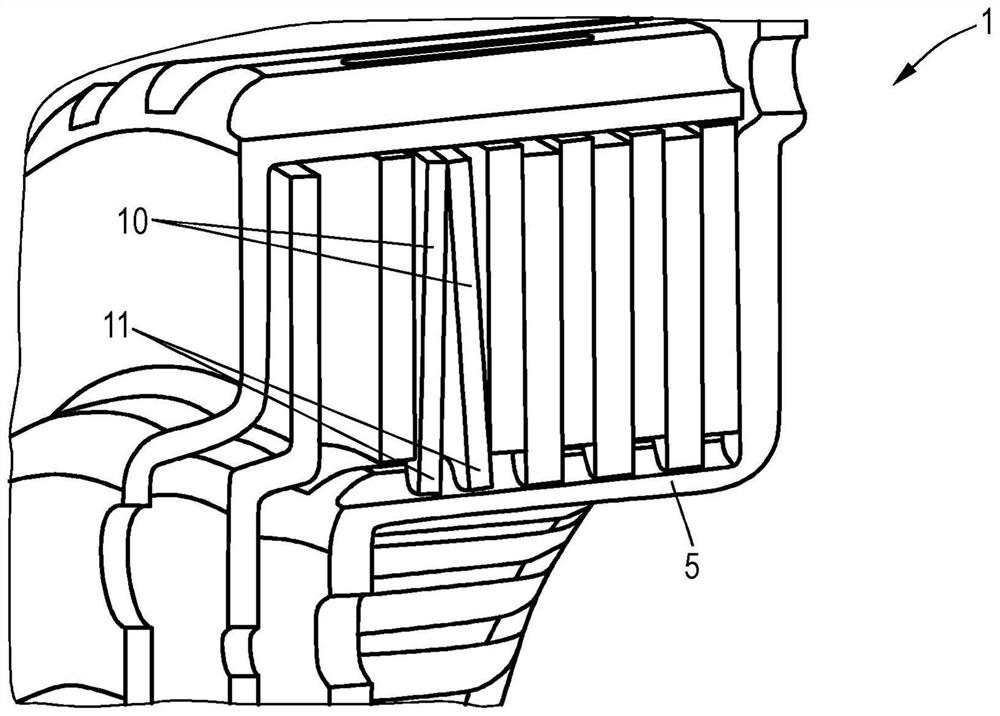

[0024] figure 1 A clutch device 1 according to the invention is shown, comprising an outer clutch plate carrier 2 with an outer clutch plate 3 arranged thereon, which in the illustrated embodiment is a friction plate 4 .

[0025] Furthermore, an inner disc carrier 5 is provided, which has an inner disc 6 , here a steel disc 7 , mounted thereon. The outer and inner clutch disks 3 , 6 form a clutch disk pack which can be compressed in the axial direction by means of an actuating element 8 , for example a pressure plate. Thus, what is involved here is a "normally disengaged" clutch arrangement in which the clutch plate pack is normally disengaged and is engaged, ie compressed, by the operating member only when required, when torque is to be transmitted.

[0026] The basic structure and function of such clutch arrangements are known and need not be described in detail.

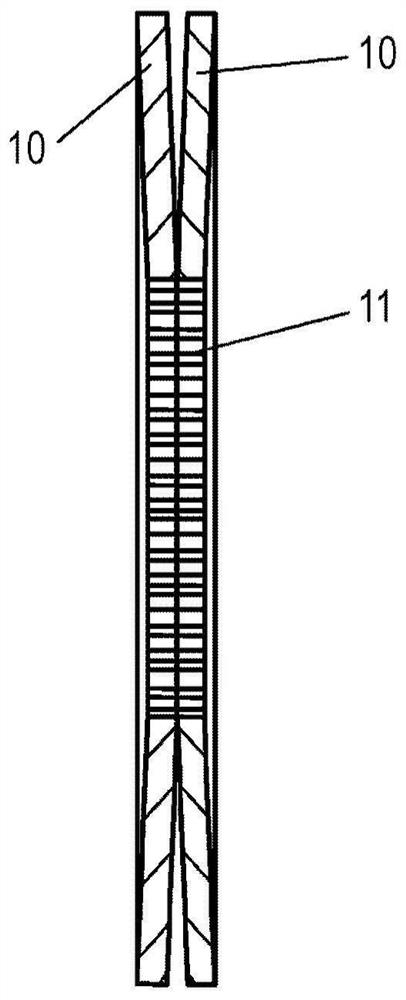

[0027] According to the invention, in the exemplary embodiment shown, the steel plate 7 is formed by two clu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com