A method for controlling the flow rate of tempering liquid during wet temper rolling of cold-rolled steel plate

A cold-rolled steel plate and rolling process technology, which is applied in the field of wet-tempered rolling of cold-rolled steel plate, can solve the problem of lack of accurate control of the surface roughness of cold-rolled steel plate, and achieve the effect of realizing precise control and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0033] In the embodiment, the tempering machine is a double-frame six-roller wet tempering machine, and the incoming material is cold-rolled steel plate annealed in a vertical continuous annealing furnace, the brand is MR T4-CA, the thickness of the steel plate is 0.19mm, and the original The average roughness is 0.491 μm, and the target roughness of the finished steel plate is 0.662 μm.

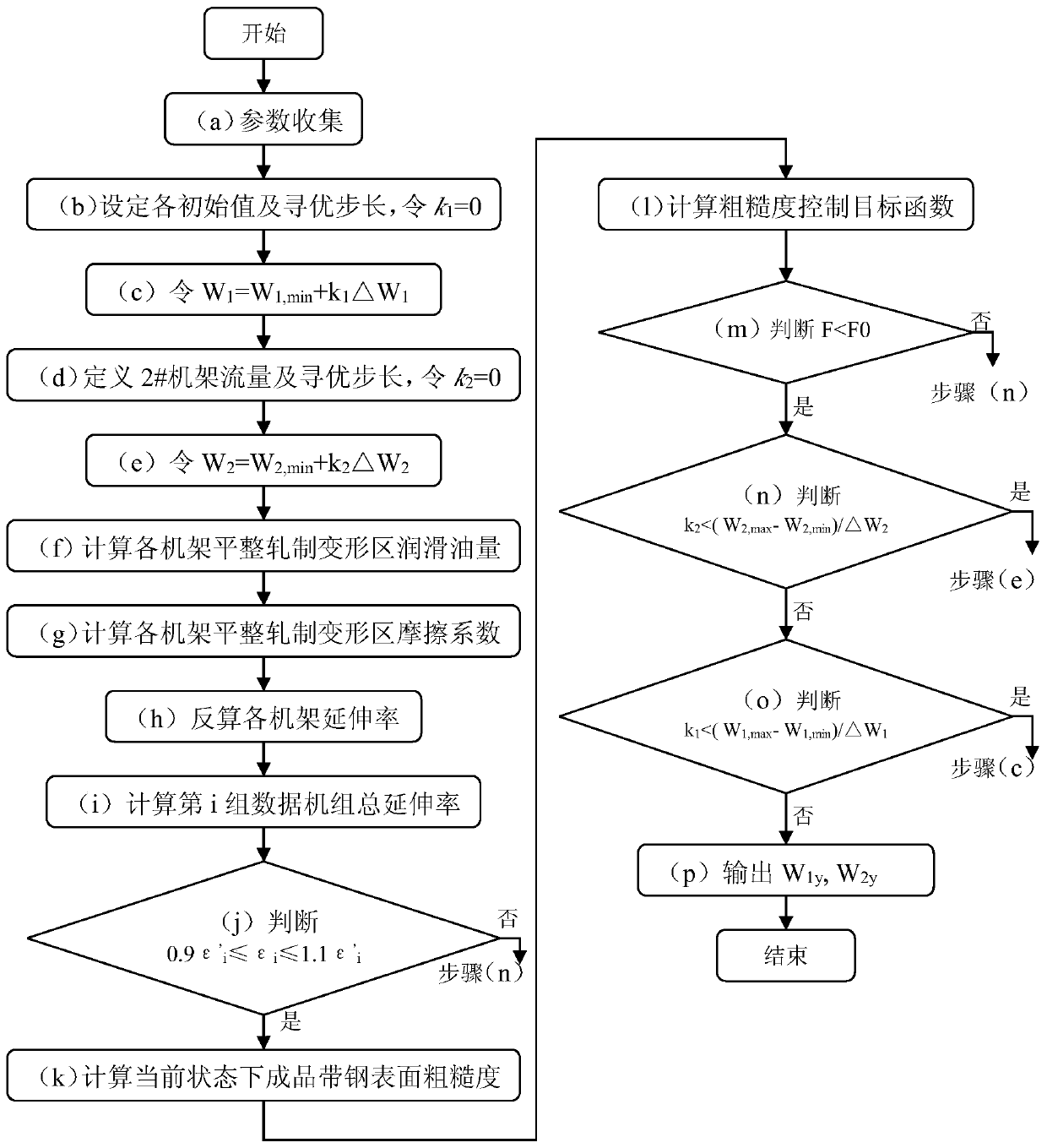

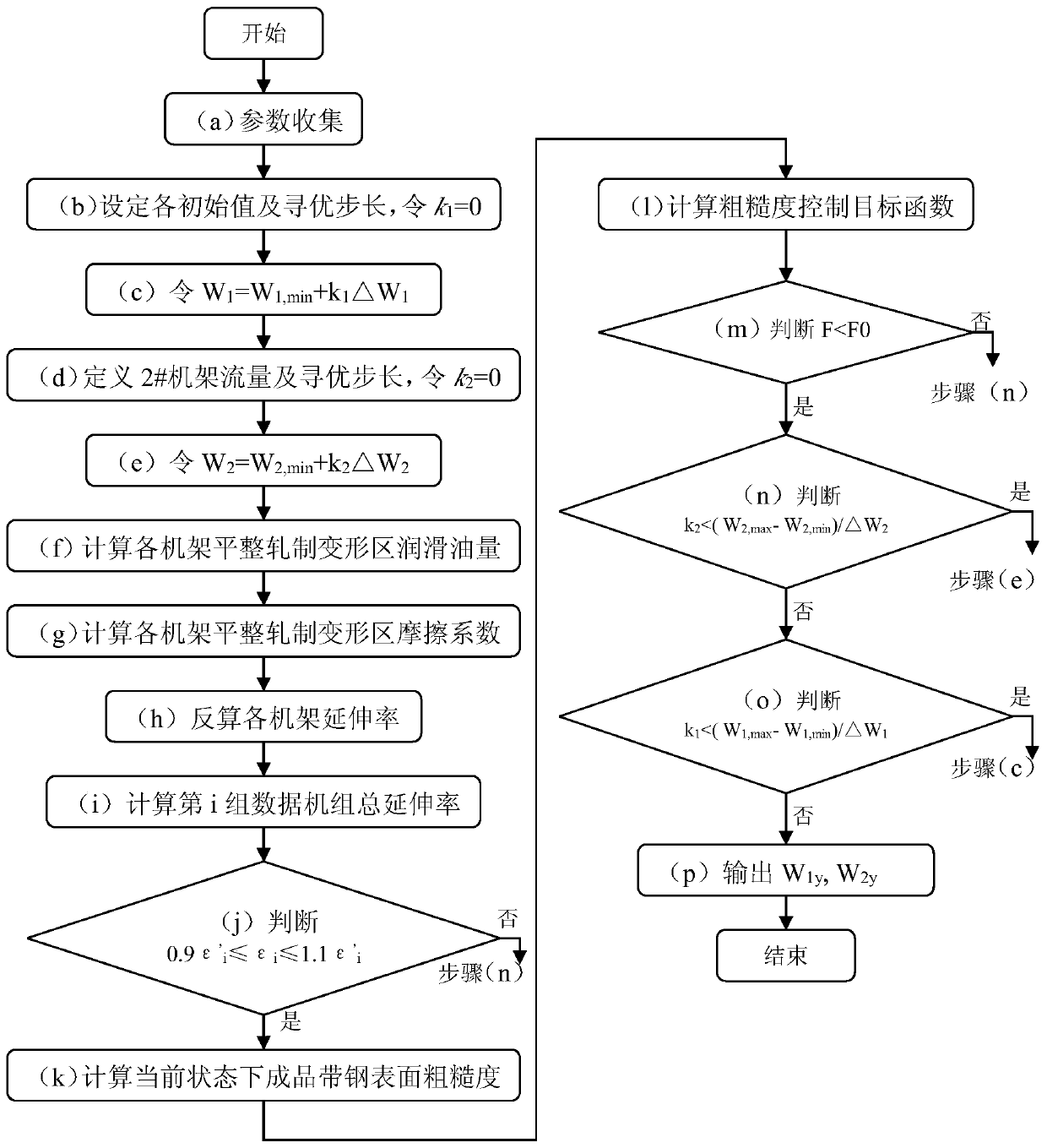

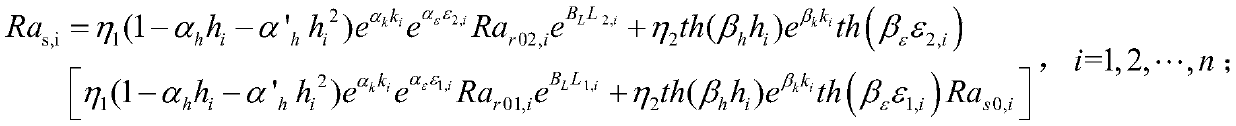

[0034] refer to figure 1 , a method for controlling the flow rate of a leveling liquid in a cold-rolled steel plate wet-leveling rolling process, comprising the following steps:

[0035] (a) Parameter collection, including: a set of raw surface roughness of the strip to be produced

[0036] Ra s0,i ={0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com