A control method of a multi-drum washing machine

A control method and washing machine technology, applied to the control device of the washing machine, other washing machines, oscillating washing machines, etc., can solve the problems of loose clothes, polyester breakage, and the washing machine cannot reach the user, so as to reduce energy consumption and improve energy utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

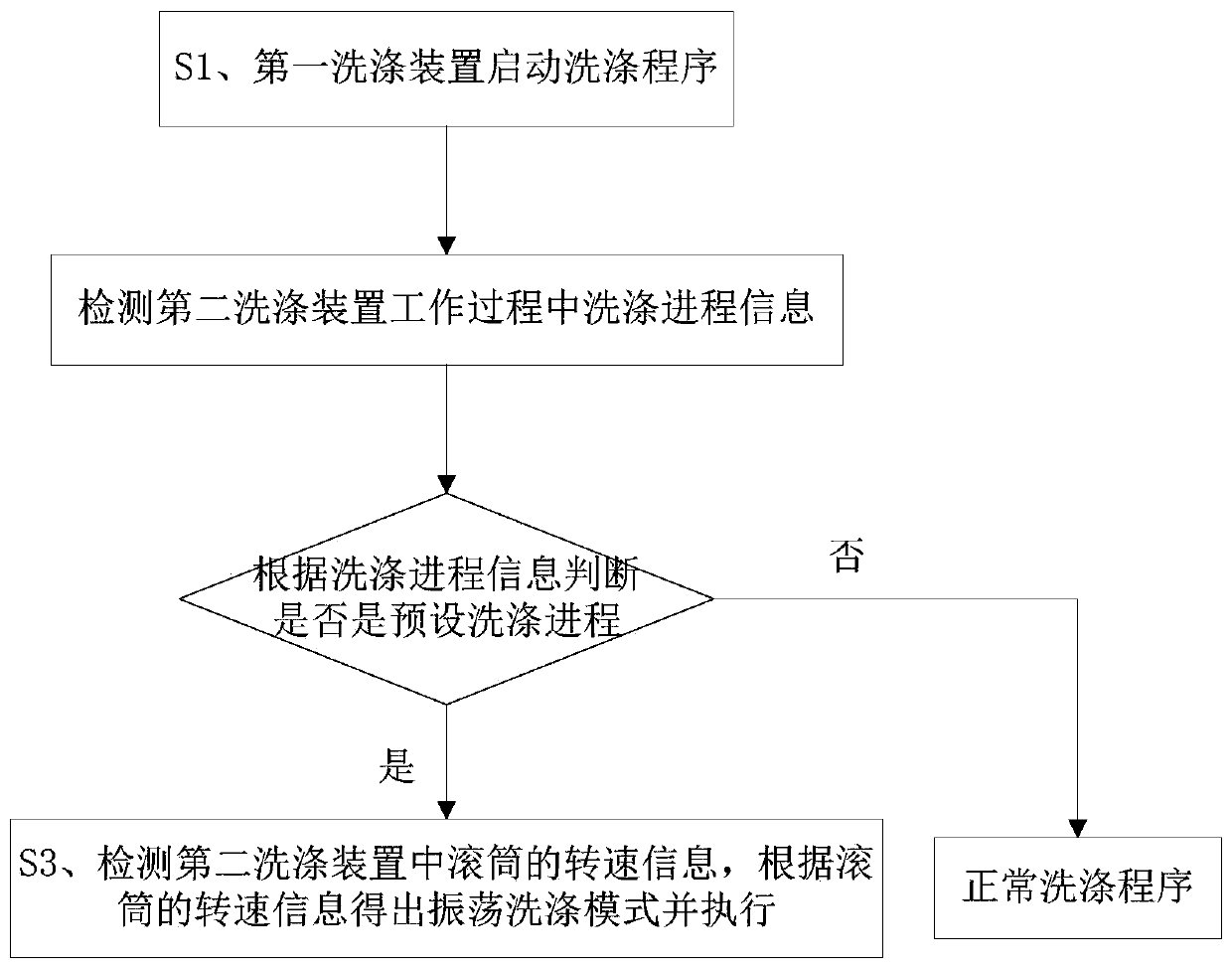

Image

Examples

Embodiment 2

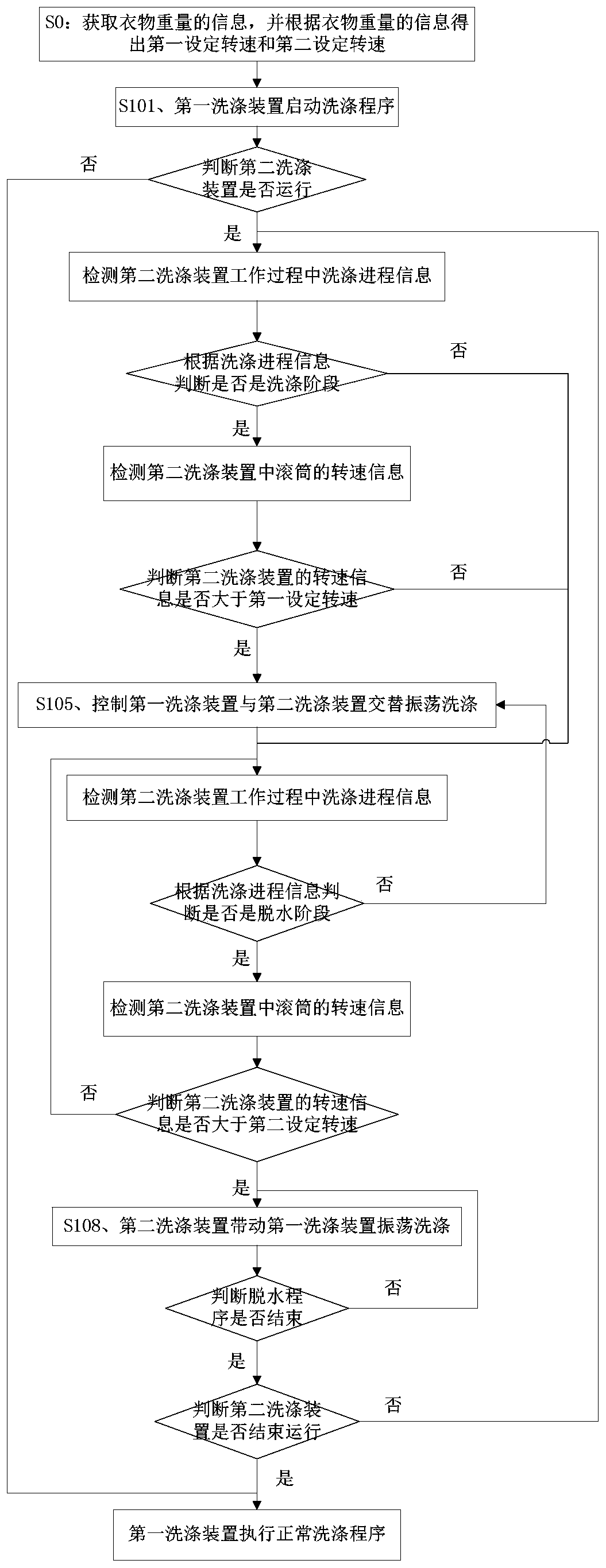

[0075] Such as figure 2 As shown, the difference between this embodiment and the foregoing embodiments is that the control method for the multi-drum washing machine described in this embodiment includes the following steps:

[0076] Step S0: Obtain the information of the weight of the clothes, and obtain the first set speed, the second set speed and the third set speed according to the information of the weight of the clothes;

[0077] S101, the first washing device starts the washing procedure;

[0078] S102. Determine whether the second washing device is running, if yes, execute step S103; if not, perform a normal washing procedure by the first washing device;

[0079] S103. Detect the washing process information during the working process of the second washing device, judge whether it is a washing process according to the washing process information, if yes, perform step S104; if not, perform step S106;

[0080] S104. Detect the rotational speed information of the drum i...

Embodiment 3

[0089] The difference between this embodiment and the above-mentioned embodiments is that the control method in this embodiment further includes: when the washing process information in step S2 is not the preset washing process, continue to judge whether the second washing device is within the set waiting time If so, wait for the second washing device to execute the preset washing process, and then execute step S3; if not, execute the normal procedure.

[0090] Alternatively, when the washing process information in step S103 is not a washing process, continue to judge whether the second washing device executes the washing process within the set waiting time, if yes, wait for the second washing device to execute the washing process, and then perform step S104 ; If not, execute step S105.

[0091] Alternatively, when the washing process information in step S106 is not the dehydration stage, continue to judge whether the second washing device performs the dehydration stage within...

Embodiment 4

[0094] The difference between this embodiment and the above-mentioned embodiments is that step S00 is included before step S1 or S0 in this embodiment to obtain information about the material of the clothes.

[0095] Then, step S3, detecting the rotation speed information of the drum in the second washing device, and obtaining and executing the oscillation washing mode according to the rotation speed information and material information of the drum.

[0096] For example, when the material of the clothes in the first washing device is soft material, and the material of the clothes in the second washing device is ordinary material, then the oscillation washing mode is only that the second washing device drives the first washing device to vibrate and wash; the first washing device is not executed. A washing device and a second washing device alternately oscillate and wash.

[0097]Alternatively, the first set rotational speed, the second set rotational speed and the third set rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com