Universal adapter for specialized valves

A technology for universal joints and user equipment, applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., can solve problems such as high risk of failure, complex structure, and large complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

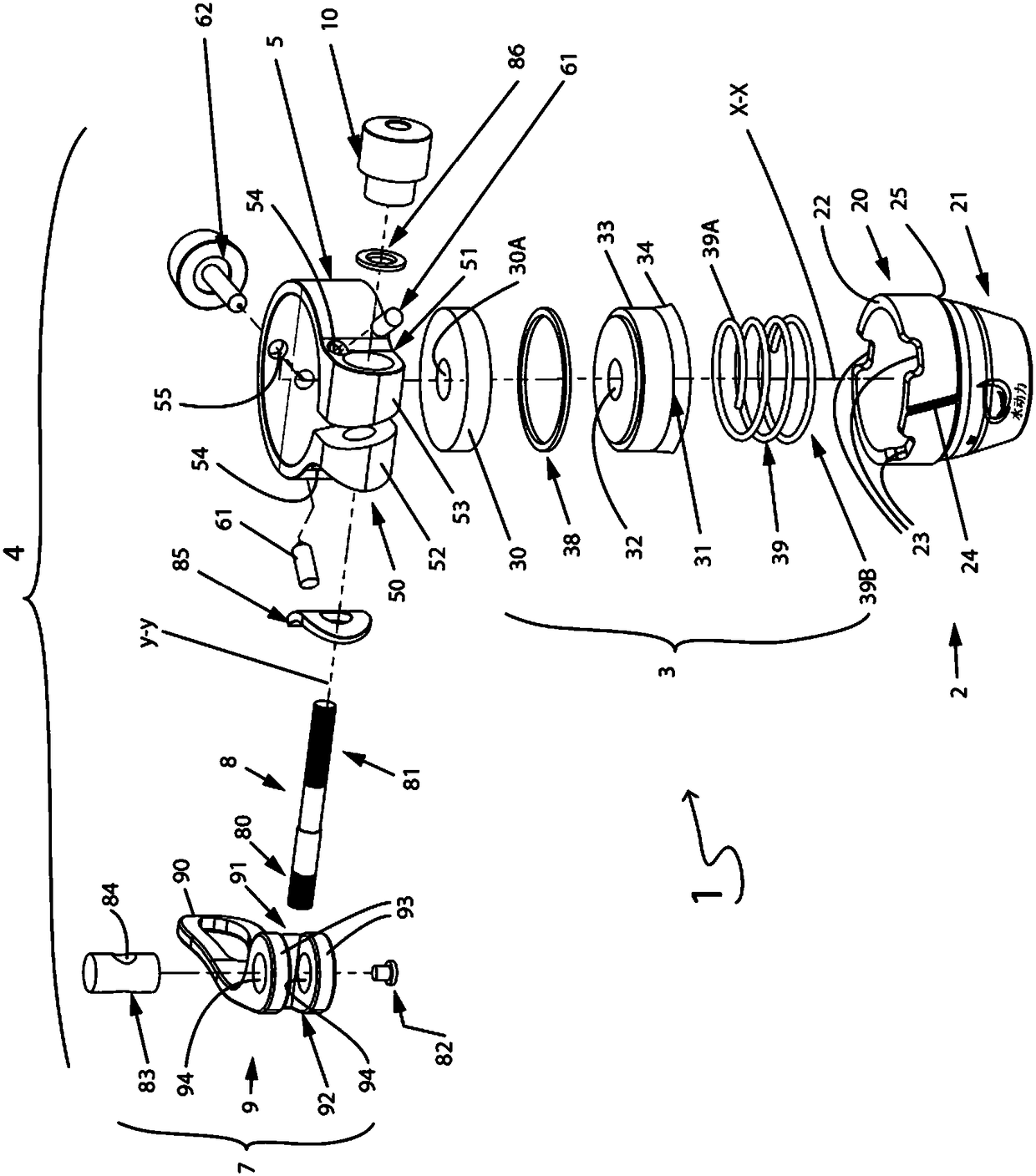

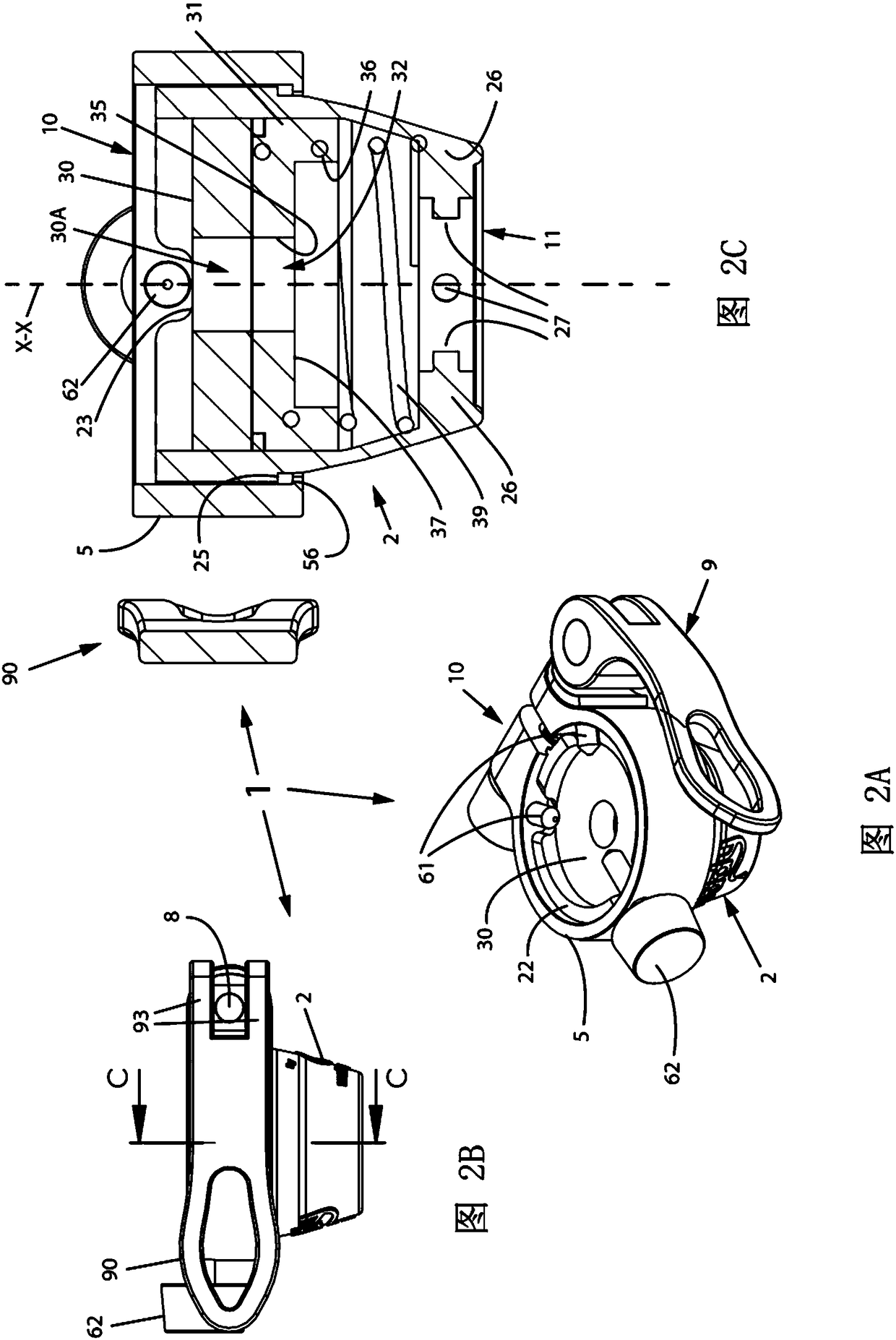

[0017] Such as figure 1 As shown in , the universal joint of the present invention is indicated by reference numeral 1 as a whole. This joint comprises a functional hollow body 2, a water sealing element 3 housed inside said hollow body and a reversible fastening element 4 of the hollow body connected to the opening of a valve (not shown) of the water supply system.

[0018] The functional hollow body 2 is a substantially hollow cylinder, preferably tapering from its first end 20 to its second end 21 along its axis XX. The first end 20 intended to be fixed to the opening of the valve shows a rounded edge 22 comprising a plurality of seats 23 for radially positioning the pin or reversible locking screw of the joint on said opening, as follows mentioned. Preferably, said seat 23 is formed by three notches spaced along the circumference of the edge 22 so as to define the three endpoints of Y. Furthermore, the outer surface of the first end may have identification markings 24 t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap