Common mode choke coil

A common-mode choke coil, first-line technology, applied in the direction of transformer/inductor coil/winding/connection, inductor, fixed transformer or mutual inductance, etc., can solve the problems of mode conversion characteristics reduction, easy inconsistency, etc., to achieve mode Effects with good transformation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

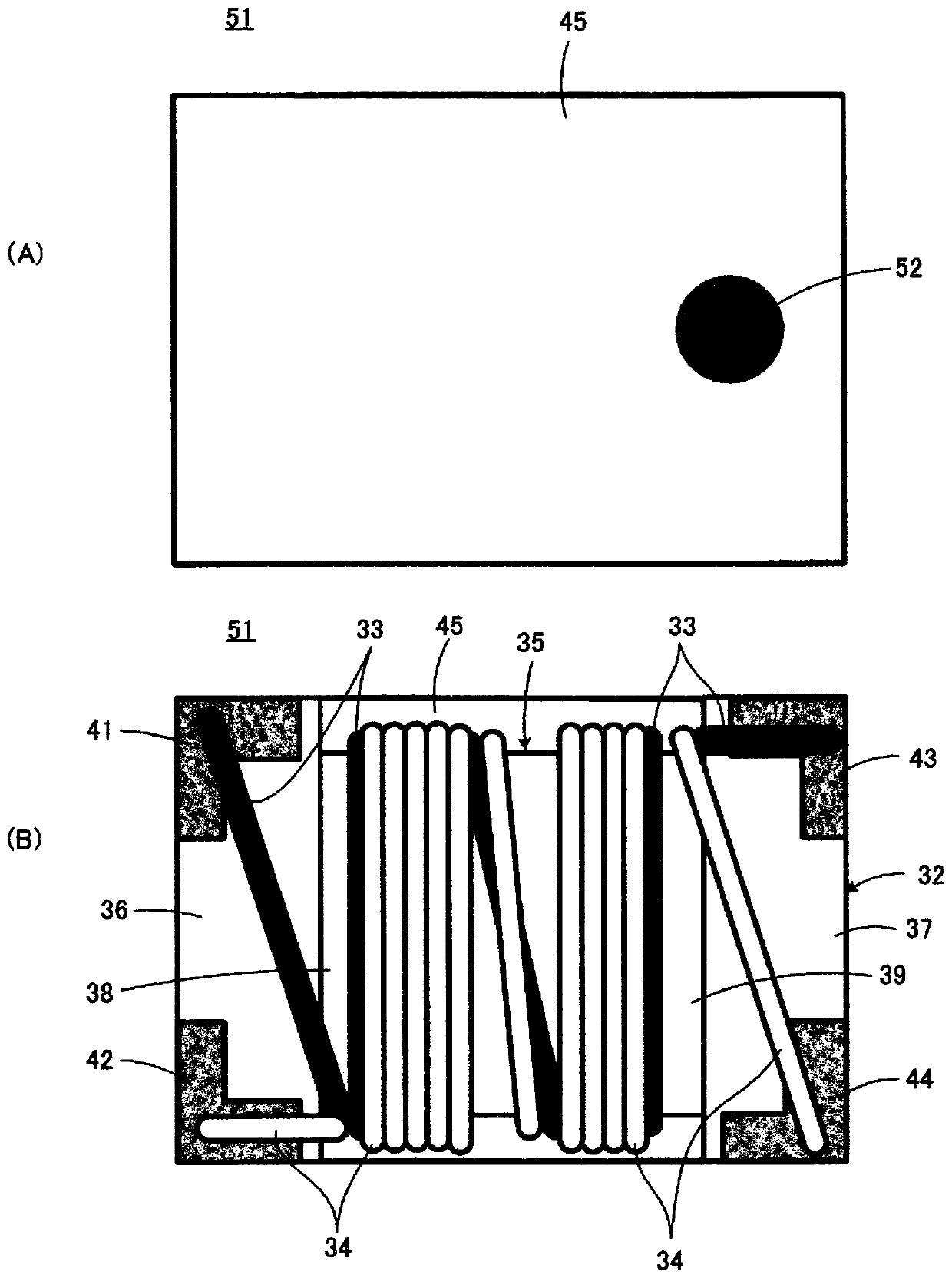

[0060] figure 1 The common mode choke coil 51 based on the first embodiment of the present invention is shown. With the above Picture 11 Compared with the common mode choke coil 31 shown, figure 1 The common mode choke coil 51 shown differs only in the winding method of the first wire 33 and the second wire 34, and the other configurations are substantially the same. Thus, in figure 1 Middle, right and Picture 11 Elements corresponding to the elements shown are denoted by the same reference numerals, and repeated descriptions are omitted.

[0061] in figure 1 In order to clearly distinguish the first line 33 and the second line 34, the first line 33 is schematically illustrated with black, and the second line 34 is schematically illustrated with a hollow.

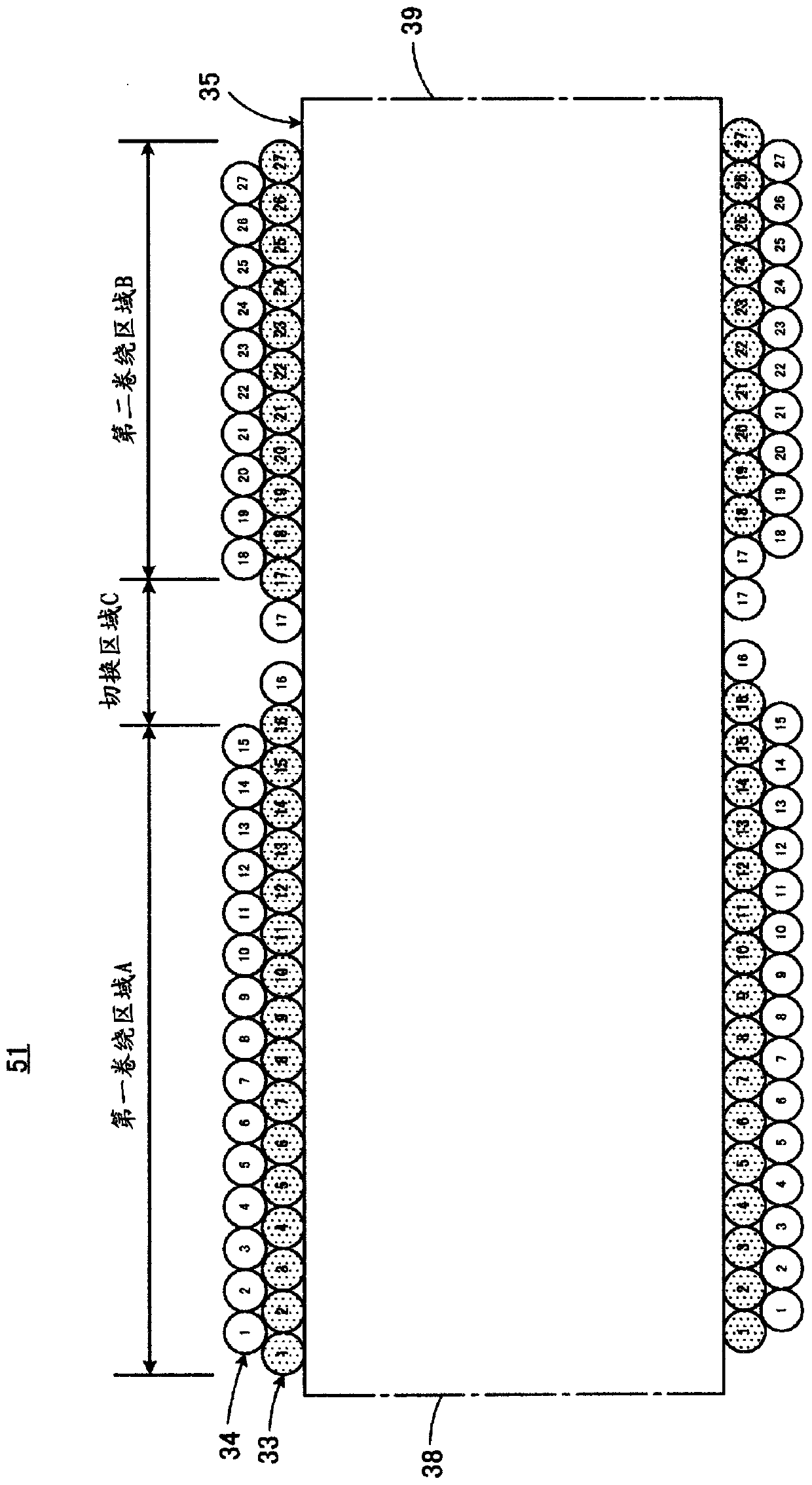

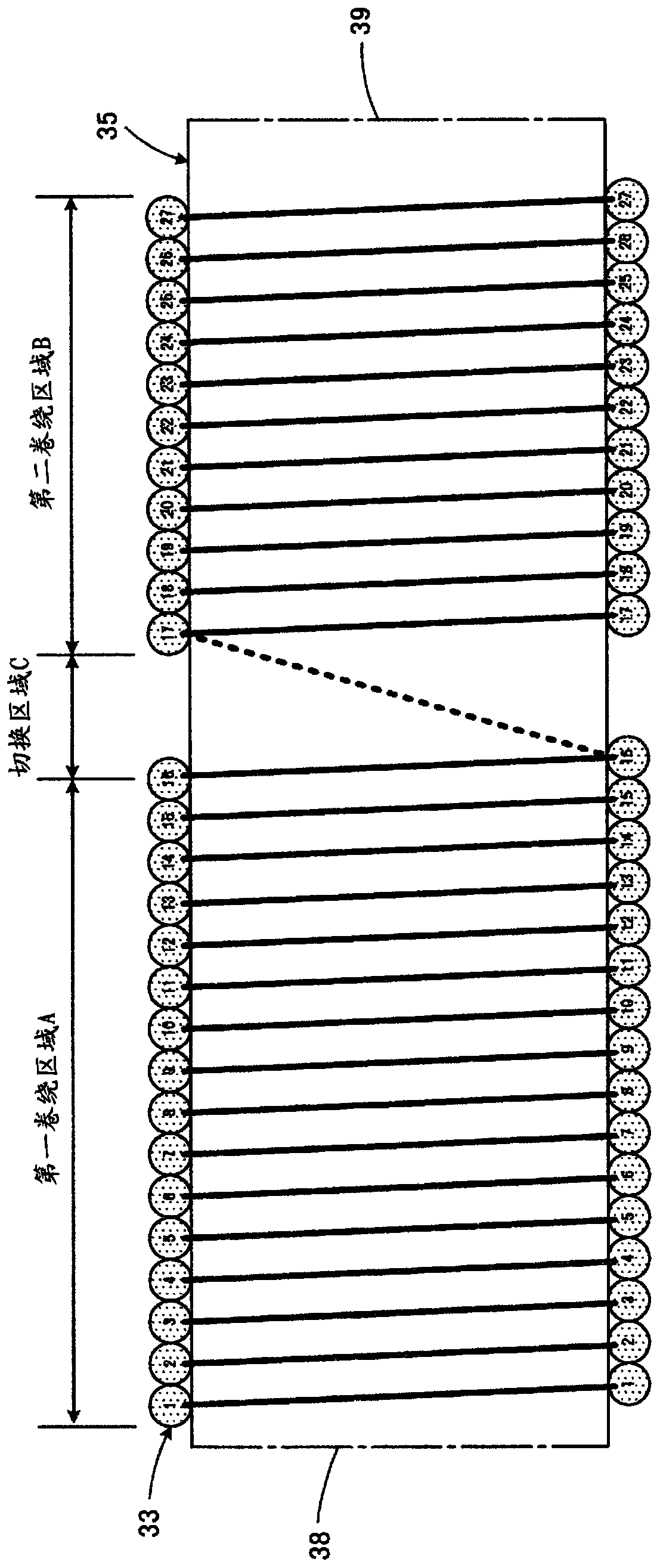

[0062] in figure 2 Shown in a schematic cross-sectional view figure 1 The winding state of the first wire 33 and the second wire 34 in the common mode choke coil 51 is shown. Compared figure 1 (B) and figure 2 , About t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap