Novel central circular hole type range hood rectifying plate

A round-hole lampblack and rectifying plate technology is applied in the fields of lampblack removal, heating mode, household heating, etc. It can solve the problems that the structural form affects the airflow distribution and the lampblack capture effect of the lampblack machine, so as to improve the lampblack capture path. , good oil fume capture effect, improve the effect of oil fume capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

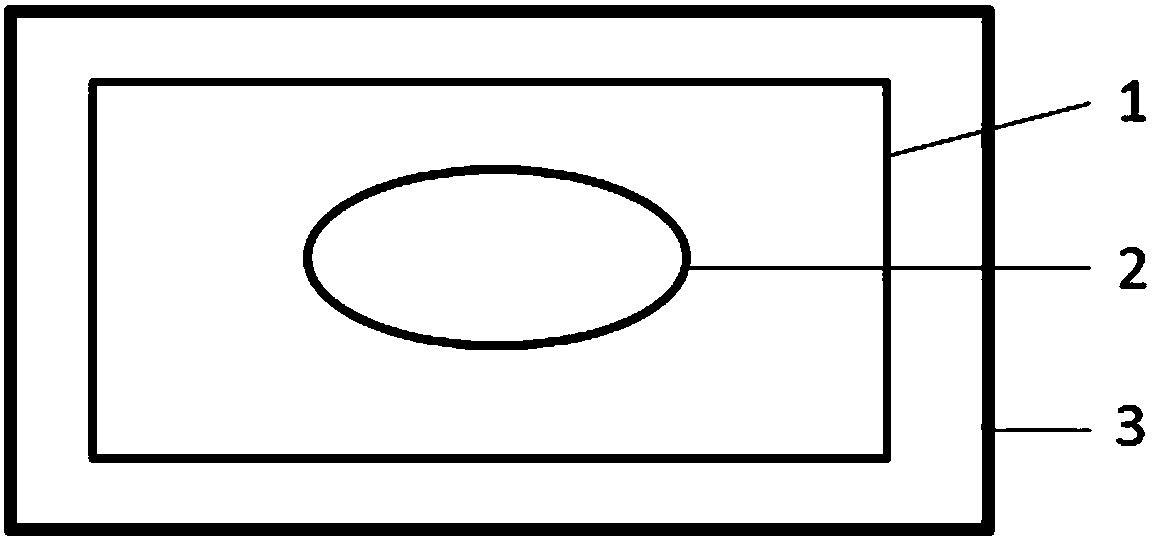

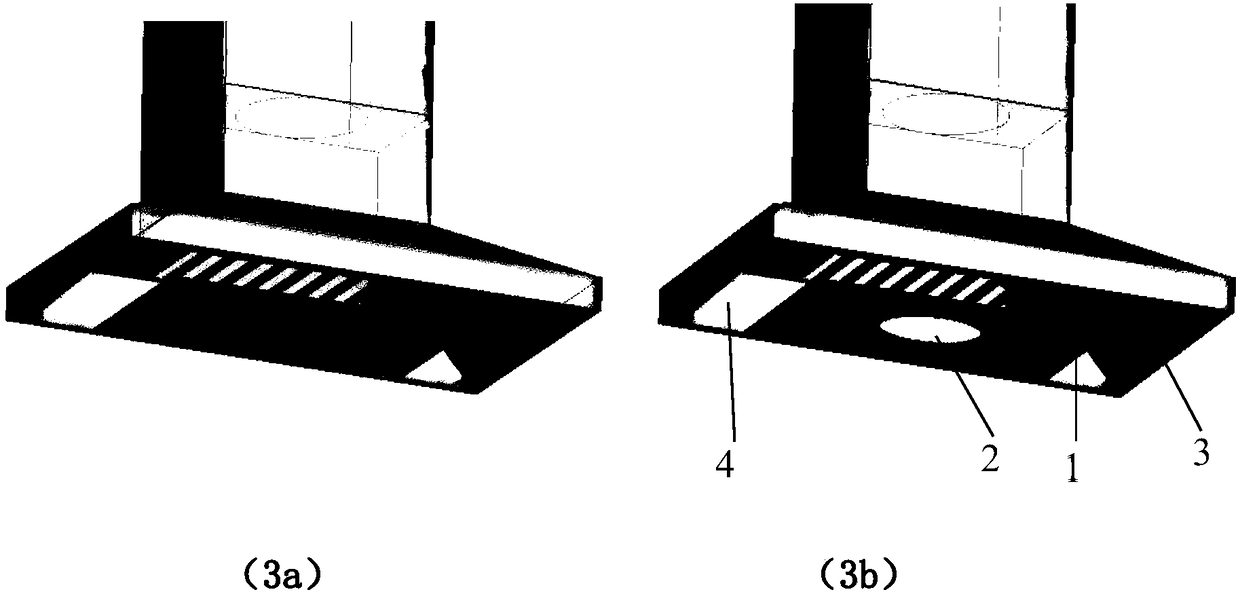

[0017] Such as figure 1 As shown, it is a schematic diagram of a rectifying plate of a novel central circular hole range hood of the present invention. The new rectifying plate includes the widely used square rectifying plate 1 and the edge 3 of the fume hood; a central round hole 2 (that is, an elliptical opening in the center of the rectifying plate) is set in the center of the square rectifying plate, which directly faces the air duct opening to generate upward exhaust air. The speed is relatively high, and the exhaust air in the center guides most of the rising oil fume from the left or right stove to the center of the fume hood to quickly suck it away; there is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com