C-type tubing cutter

A technology of pipe cutters and cutters, which is applied in the direction of pipe shearing devices, shearing devices, manufacturing tools, etc., and can solve problems such as time-consuming and monotonous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

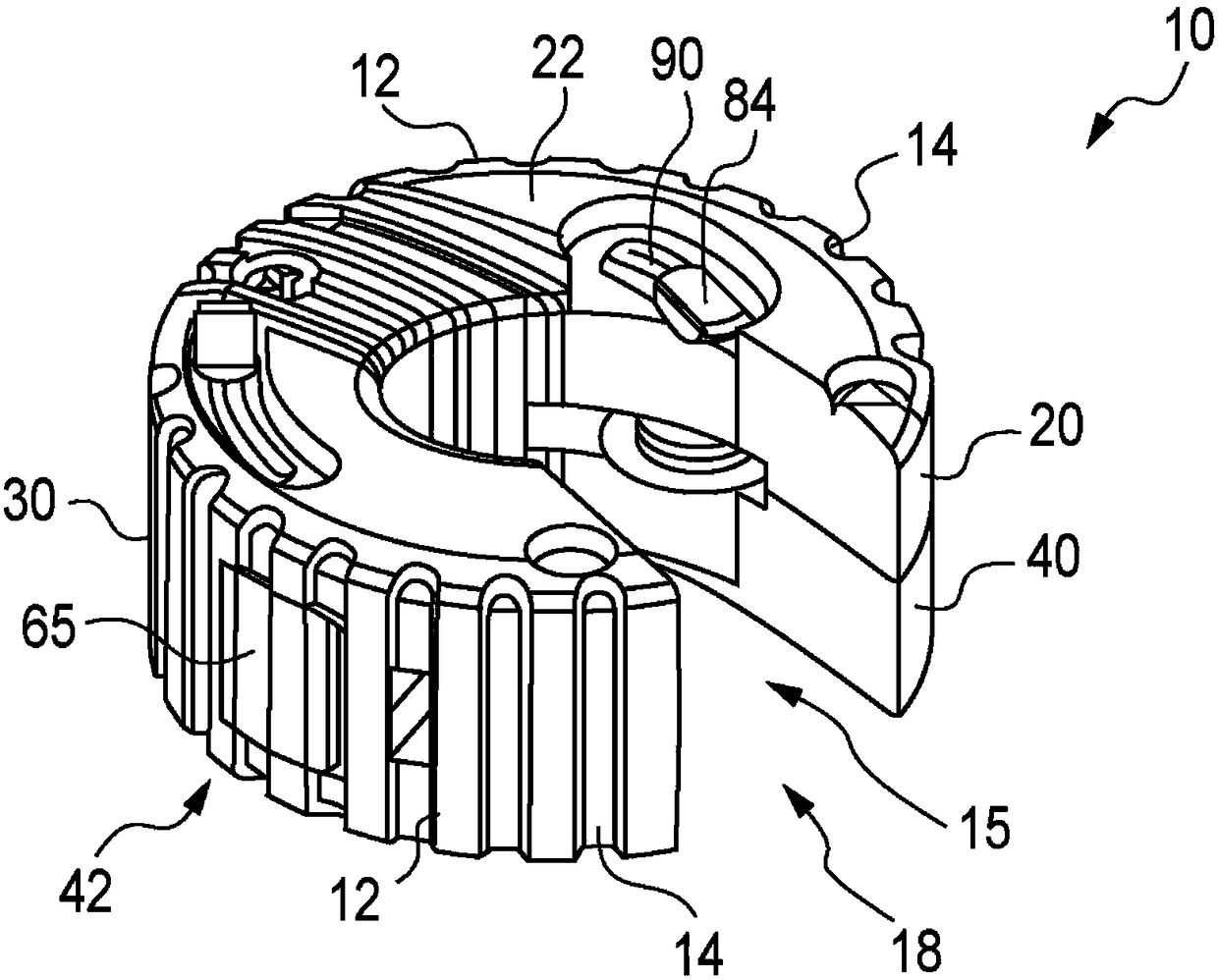

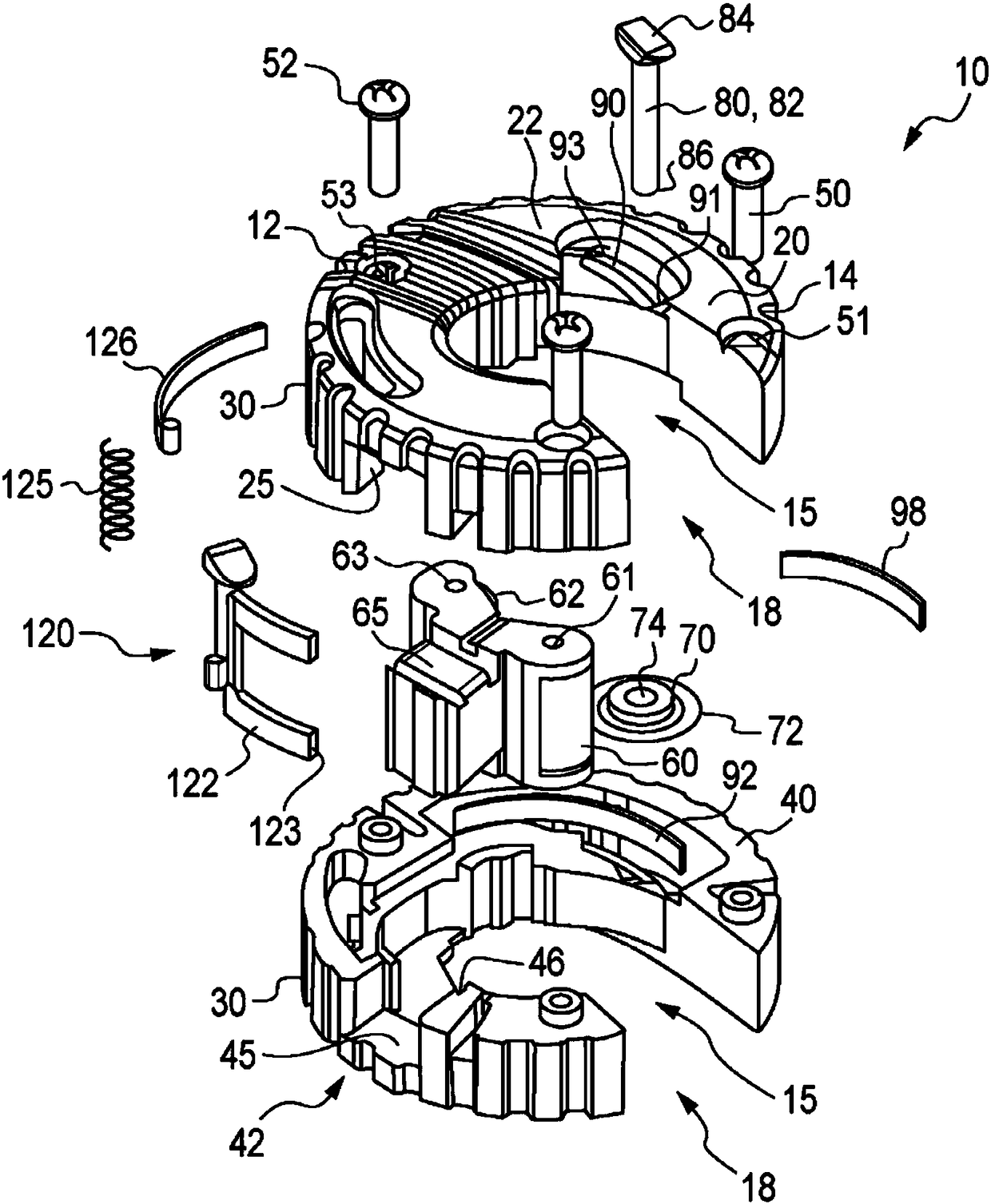

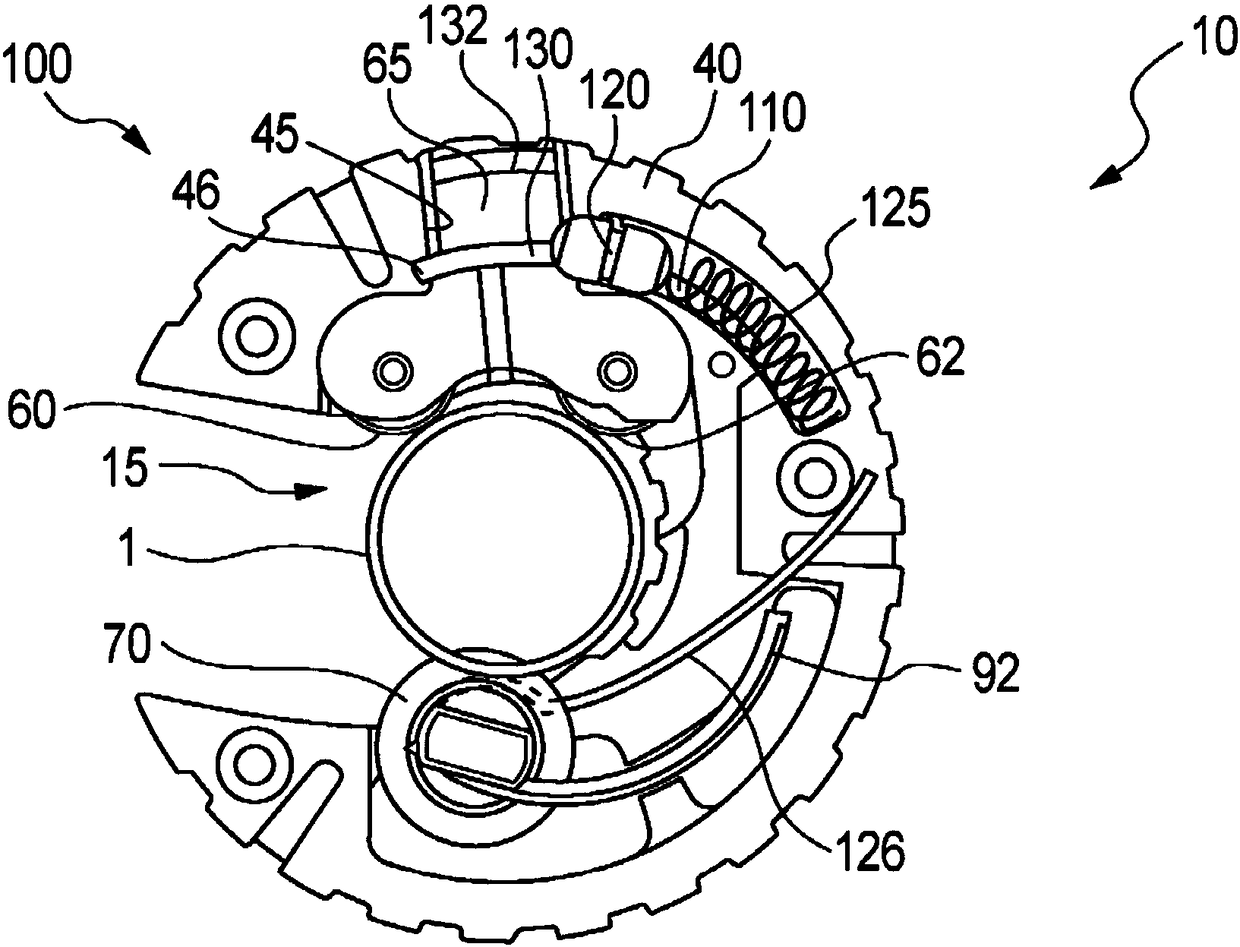

[0020] This subject provides a C-tube cutter that can be used to cut a range of different sizes of tube, pipe or other workpiece. Although the terms "pipe" or "pipe" are generally used herein, it should be understood that the subject cutter can be used to cut or severe various other types of workpieces. In many embodiments, the cutter utilizes a size index assembly that selectively accommodates multiple discrete sizes of tubing. The size index assembly can be quickly and easily adjusted so that the cutter can receive and cut different size tubes.

[0021] In some embodiments, the pipe cutter has a selectively positionable idler housing. Typically, the roller housings can be positioned radially. The roller housing may be selectively locked in one of a plurality of discrete predetermined positions by a movable trigger. Specifically, in many forms of cutters, the trigger is slidable along an arcuate slot provided in the housing and biased toward a locked position. When the tr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap