Relief valve device and high-pressure pump using same

A safety valve and valve body technology, applied in safety valves, valve devices, fuel injection devices, etc., can solve the problems of valve component lift fluctuation, pressure reduction degree fluctuation, damage to the spring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

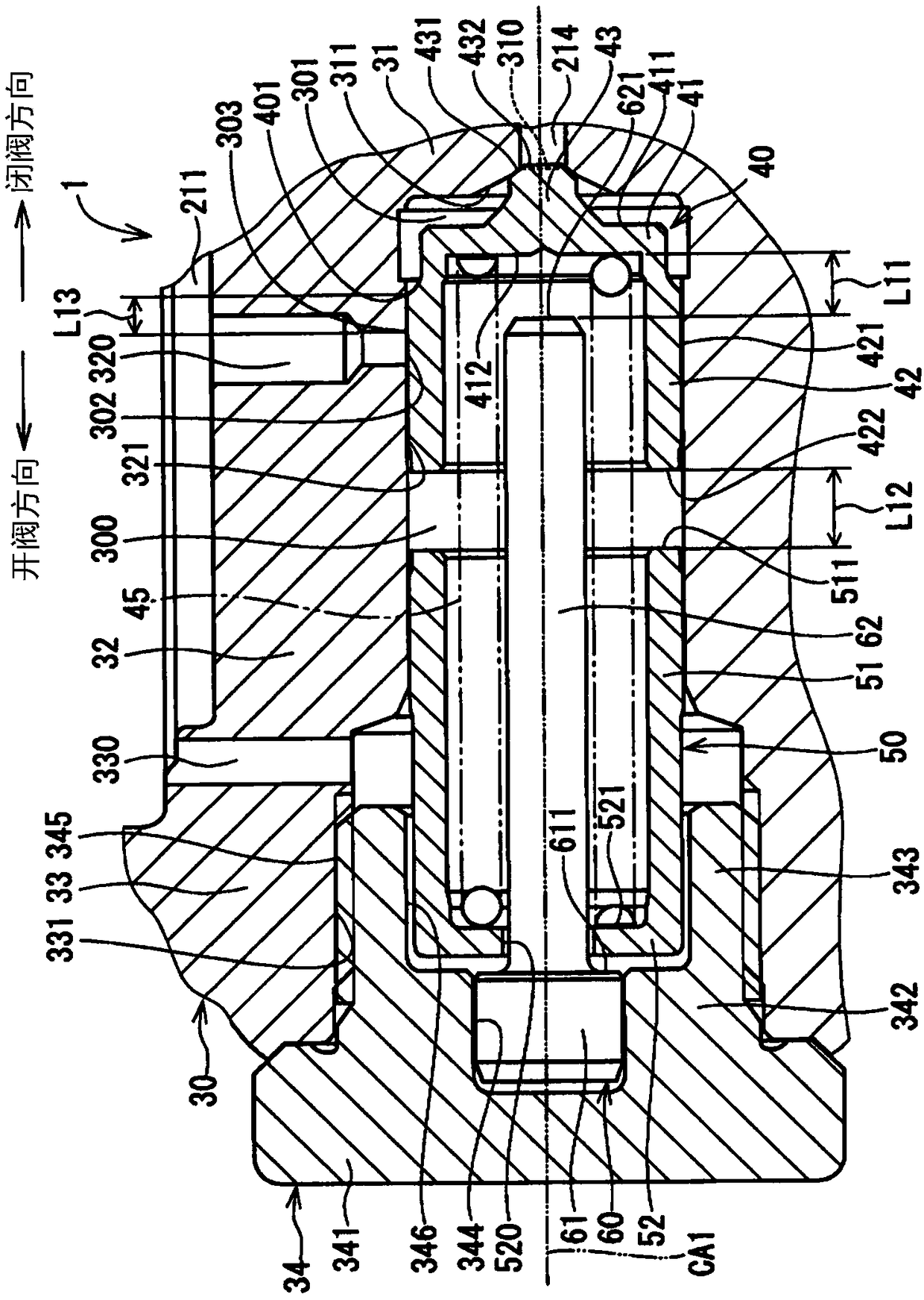

[0027] based on figure 1 , figure 2 The safety valve 1 which is the "safety valve device" which concerns on 1st Embodiment of this application is demonstrated.

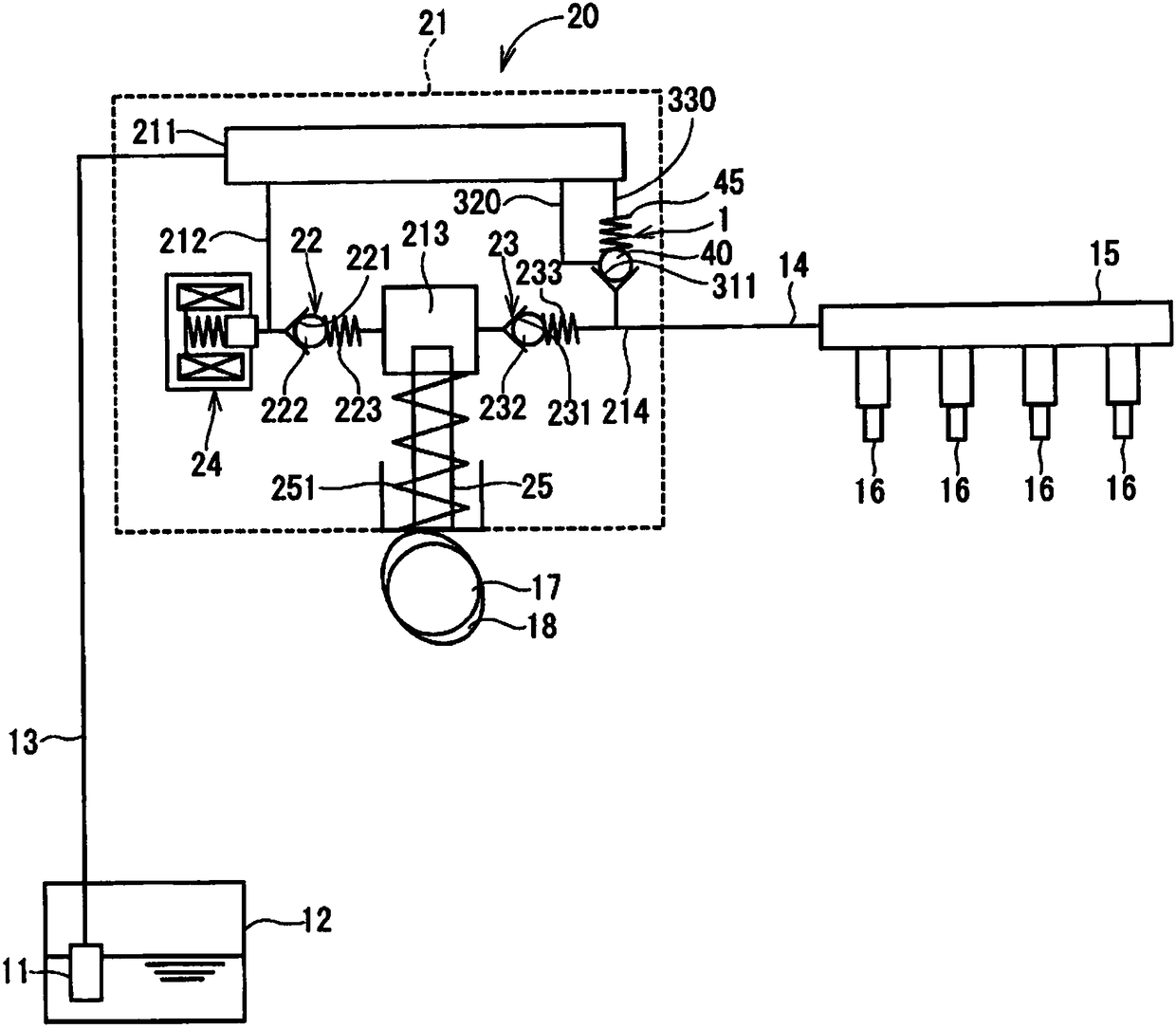

[0028] Such as figure 2 As shown, the safety valve 1 is provided on the high-pressure pump 20 . The high-pressure pump 20 is provided on a vehicle not shown. The vehicle referred to here can run, for example, using a gasoline-fueled internal combustion engine as a drive source.

[0029] The fuel pump 11 sucks fuel stored in the fuel tank 12 and supplies it to the high-pressure pump 20 through the pipe 13 . The high-pressure pump 20 pressurizes and discharges the fuel supplied from the fuel pump 11 , and supplies the fuel to the fuel rail 15 via the pipe 14 . The high-pressure fuel accumulated in the fuel rail 15 is supplied to the internal combustion engine of the vehicle via a plurality of injectors 16 connected to the fuel rail 15 .

[0030] The high-pressure pump 20 includes a pump housing 21 as a “casing”,...

no. 2 approach

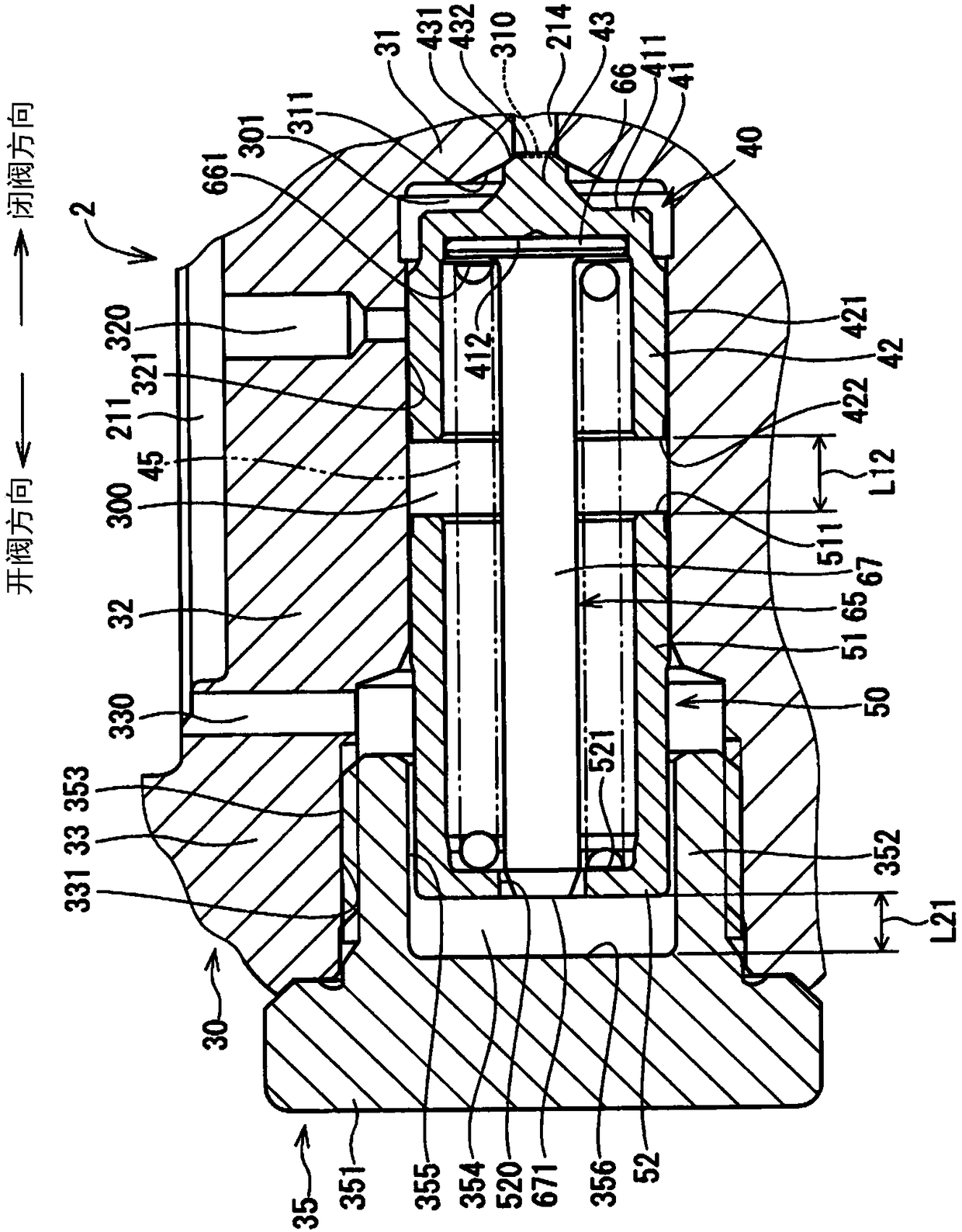

[0087] based on image 3 A safety valve device according to a second embodiment of the present application will be described. In the second embodiment, the valve housing and the stopper are different from the first embodiment.

[0088] The safety valve 2 as a "relief valve device" has a valve case 30, a valve member 40, a spring 4, a regulating pipe 50, a stopper 65 as a "restricting member", and the like. In addition, in image 3 Among them, the direction in which the inclined surface 431 of the valve member 40 moves so as to abut against the inner wall 311 of the valve housing 30 is referred to as the "valve closing direction", and the direction in which the inclined surface 431 moves so as to be separated from the inner wall 311 is referred to as the "opening direction". "Valve Direction" for illustration.

[0089] The valve housing 30 includes a valve seat portion 31 , a first cylinder portion 32 , a second cylinder portion 33 , a plug 35 serving as a “second valve body...

no. 3 approach

[0100] based on Figure 4 A safety valve device according to a third embodiment of the present application will be described. In the third embodiment, the restricting member is different from the first embodiment.

[0101] The safety valve 3 as a "relief valve device" has a valve member 40, a valve case 30 having a plug 35, a spring 45, an adjustment pipe 50, a stopper 70 as a "restricting member", and the like. In addition, in Figure 4 Among them, the direction in which the inclined surface 431 of the valve member 40 moves so as to abut against the inner wall 311 of the valve housing 30 is referred to as the "valve closing direction", and the direction in which the inclined surface 431 moves so as to be separated from the inner wall 311 is referred to as the "opening direction". "Valve Direction" for illustration.

[0102] The limiter 70 is disposed on the radially outer outer wall 421 of the sliding portion 42 . Specifically, the stopper 70 fits into the inner groove 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com