Double-safe anti-reset temperature controller

A dual protection, thermostat technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of bimetal cooling, reset, repeated dry burning, damage to the thermostat, failure, etc., to achieve a simple structure and improve production efficiency. , the effect of convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

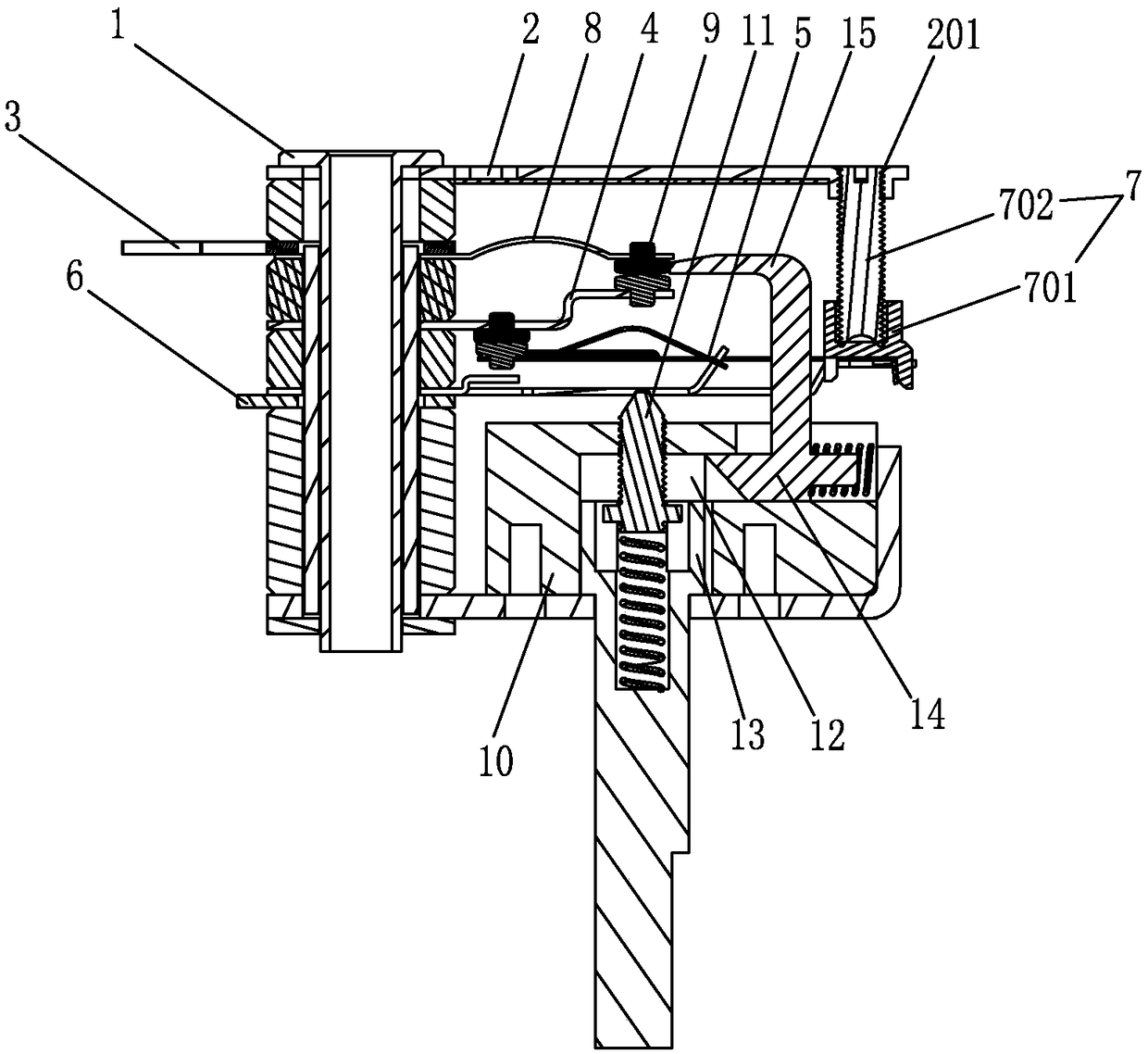

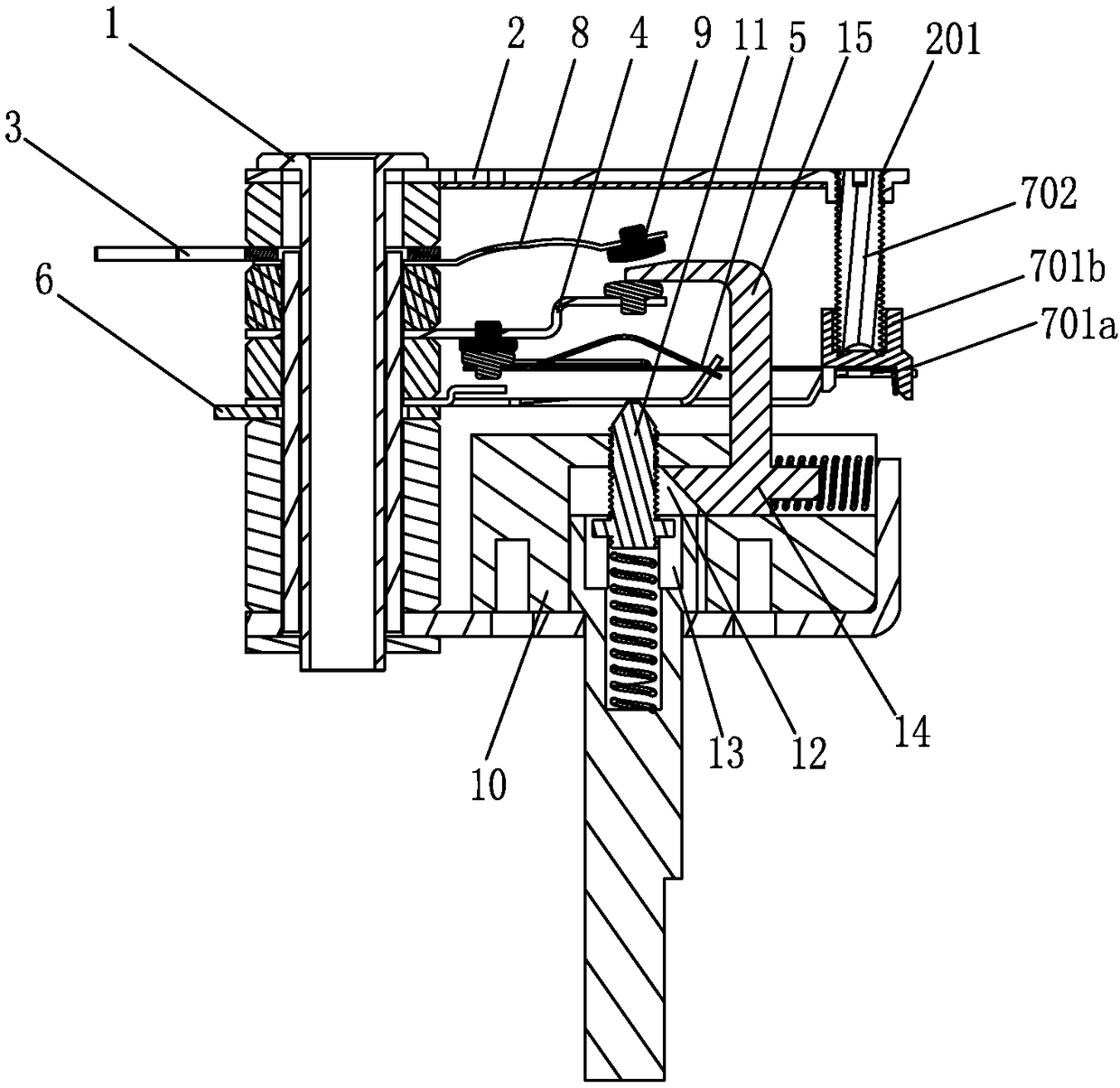

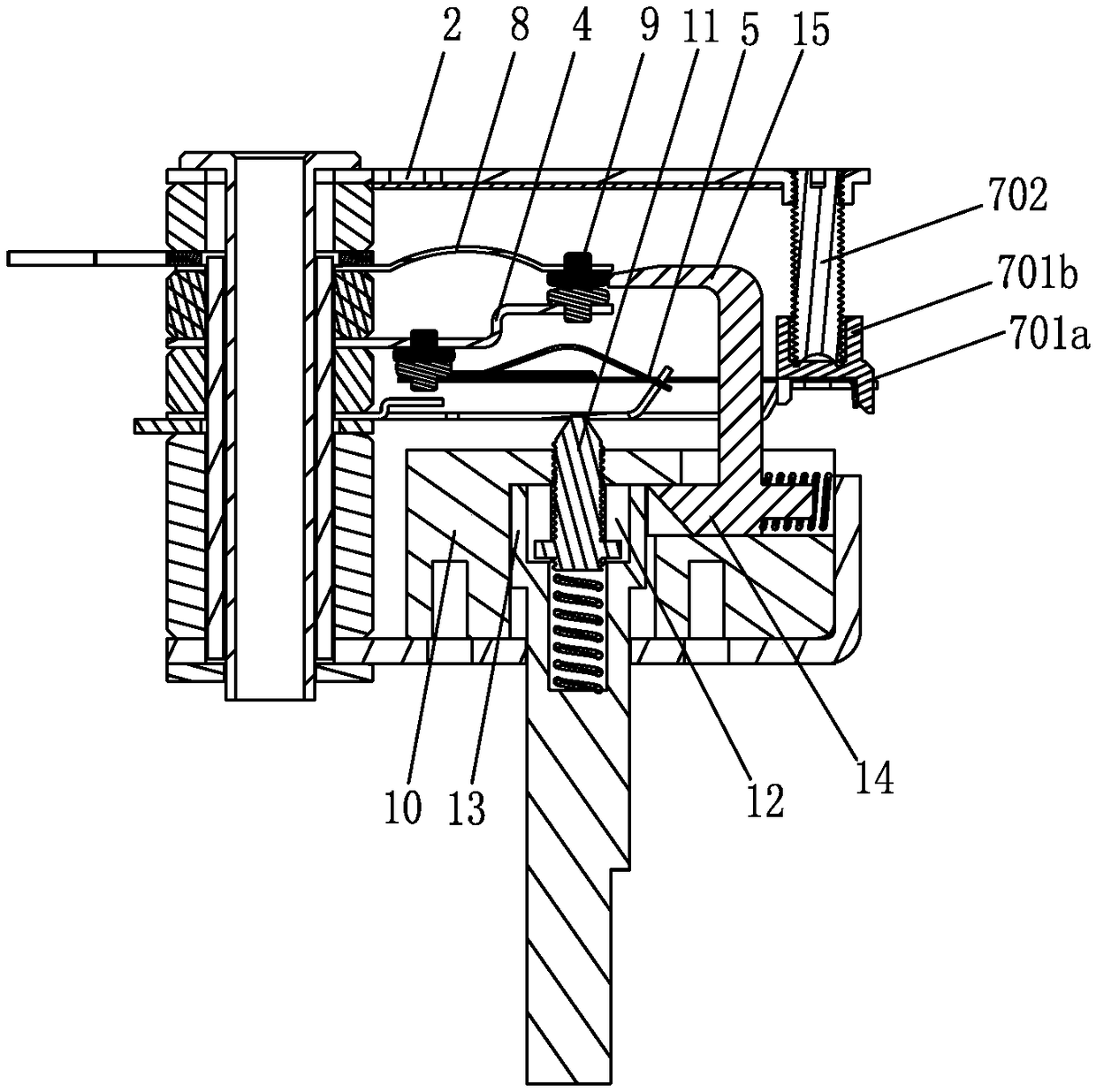

[0028] Such as figure 1 As shown, a dual-protection anti-reset thermostat includes an insulating column 1 on which a first bimetal 2, an upper terminal 3, a static contact 4, a moving contact assembly 5 and a The lower terminal 6 connected to the moving contact piece assembly 5, one end of the moving contact piece assembly 5 is electrically connected to the static contact piece 4, and the other end of the moving contact piece assembly 5 is installed between the movable end of the first bimetal 2 Insulation adjustment device 7, the upper terminal 3 is electrically connected with a second bimetal 8, the movable end of the second bimetal 8 is equipped with an upper movable contact 9, and the upper movable contact 9 is electrically connected to the static contact 4. connection; under normal conditions, the thermostat is provided with a first bimetal 2 stru...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap