a coupler

A technology of couplers and moving contacts, which is applied in the field of couplers, can solve the problems of easy aging of electrical appliances, increase production costs, and shorten lifespan, and achieve the effects of solving inaccurate specified stability values, reducing production costs, and facilitating installation and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

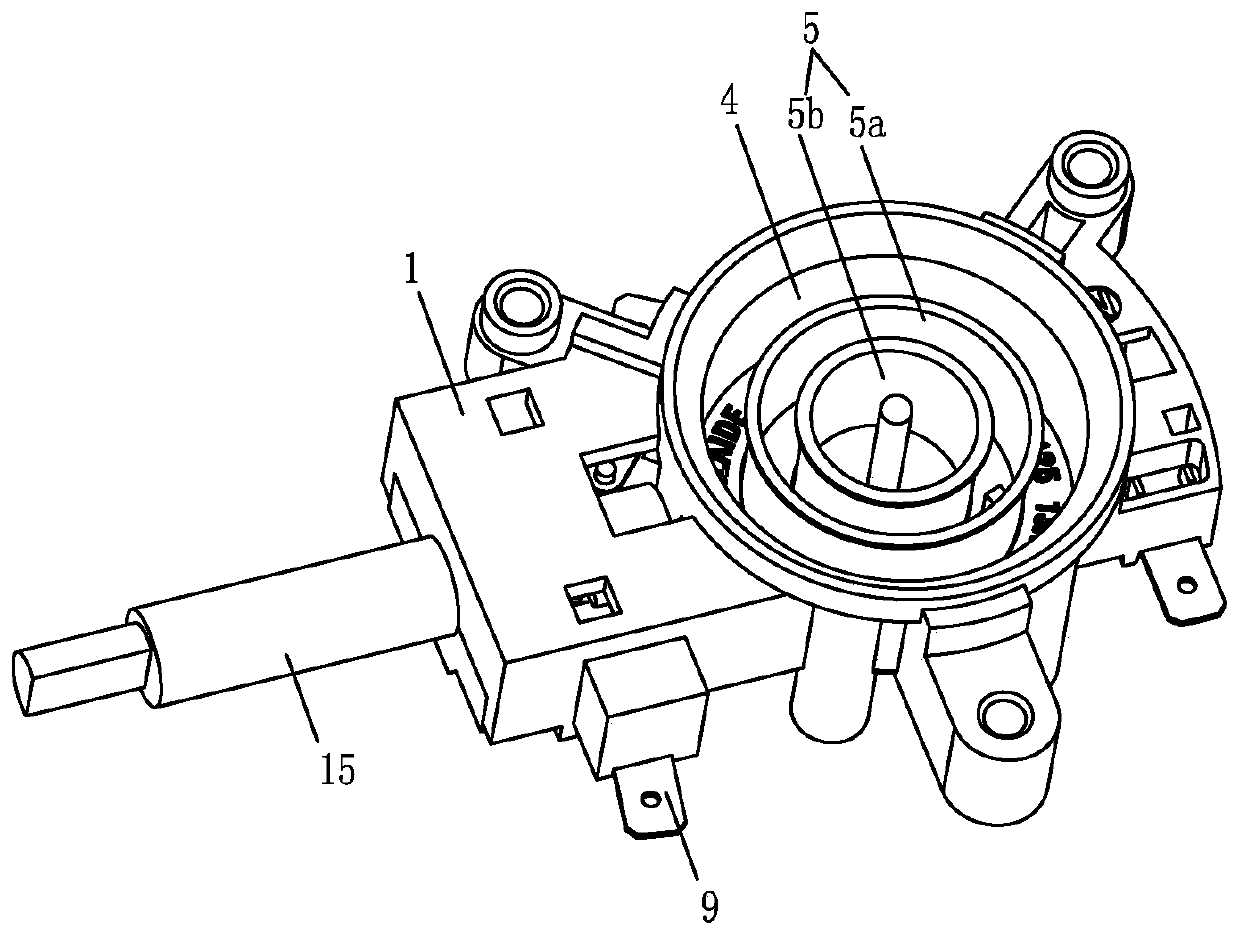

[0047] Example one, such as Figure 1 to Figure 2 As shown, a coupler includes an upper coupler 1, a plug cavity 4 is opened at the bottom of the upper coupler 1, a conductor 5 is fixed in the plug cavity 4, and a first connector connected to the conductor 5 is installed on the upper coupler 1. The movable contact piece 8, each first movable contact piece 8 is electrically connected with the corresponding first static contact piece 9, and further includes an adjusting rod 15 extending on the adjusting rod 15 to contact and cooperate with the first moving contact piece 8. Section 16. The coupler of this structure is simple and compact, quick to assemble, and reduces production costs. It enables the coupler to quickly switch on multiple heat preservation functions, and can accurately switch to the specified heat preservation value, which solves the problem of infinitely variable temperature regulation. Accurate and so on.

[0048] There are two first movable contact pieces 8 and tw...

Embodiment 2

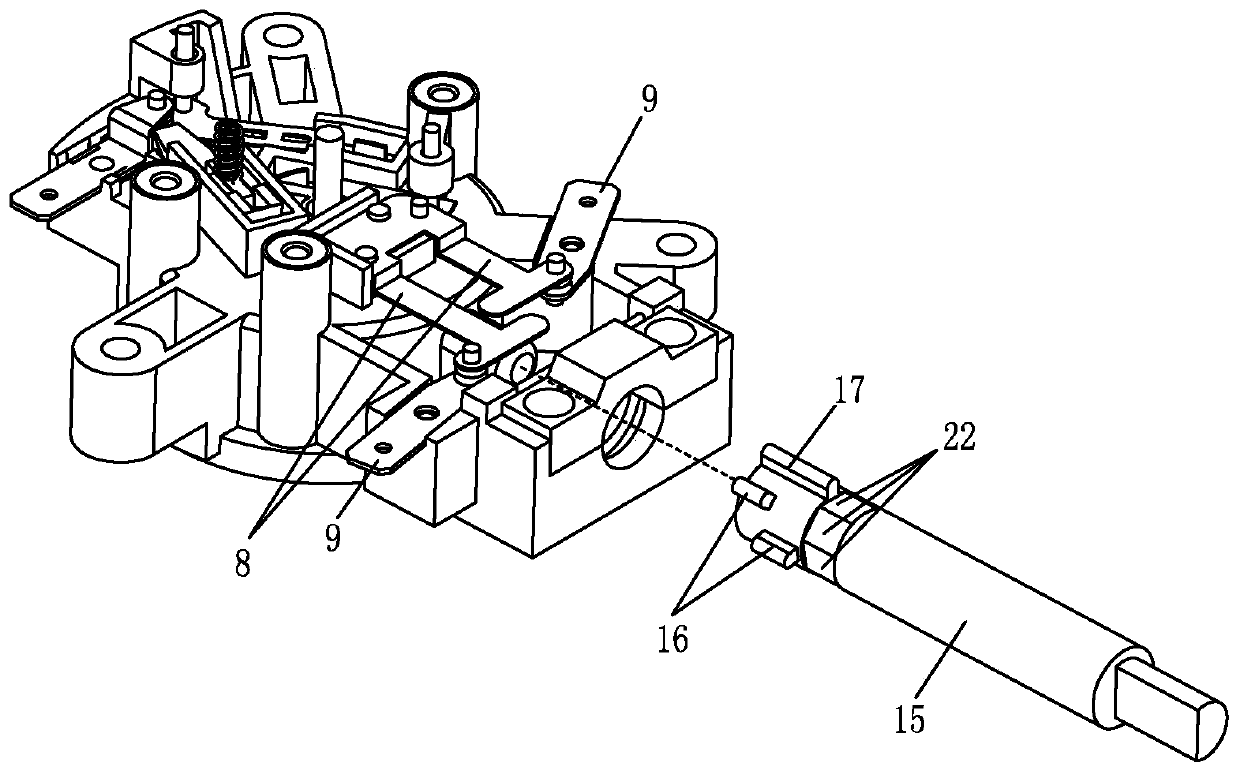

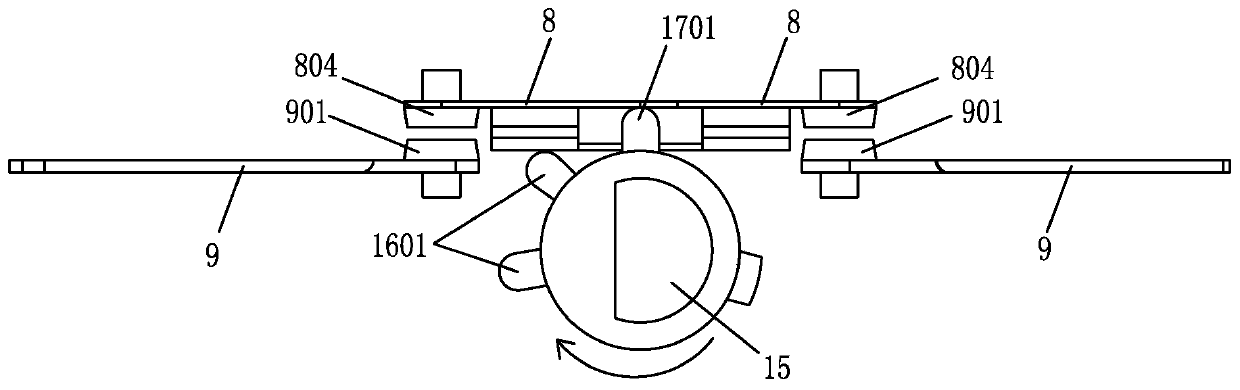

[0049] Example two, such as Figure 3 to Figure 6 As shown, the adjusting portion 16 is an adjusting convex portion 1601. By driving the adjusting rod 15, the adjusting convex portion 1601 is selectively pressed against the corresponding first movable contact piece 8, so that the first movable contact piece 8 matches the corresponding first movable contact piece 8 A static contact piece 9 is separated.

[0050] The on-off portion 17 is the on-off convex portion 1701, and the on-off convex portion 1601 is pressed against all the first moving contact pieces 8 by driving the adjusting rod 15 so that all the first moving contact pieces 8 and the first static contact piece 9 Separate and power off.

[0051] When there are two first static contact pieces 9 (for example: one first static contact piece 9 is connected to heat 100°, and the other first static contact piece 9 is connected to heat preservation 50°), the corresponding first moving contact piece 8 It is also set to two, the two...

Embodiment 3

[0053] Example three, such as Figure 7 to Figure 10 As shown, the adjusting portion 16 is an adjusting concave portion 1602. By driving the adjusting rod 15, the selected first movable contact piece 8 is pressed into the corresponding adjusting concave portion 1602, so that the first movable contact piece 8 is aligned with the corresponding first movable contact piece 8 The static contact piece 9 is turned on.

[0054] The on-off portion 17 is an on-off recess 1702. By driving the adjusting rod 15 to press all the first movable contact pieces 8 into the on-off recess 1702, all the first movable contact pieces 8 and the first static contact pieces 9 are connected and energized. .

[0055] In addition, by driving the adjusting rod 15 to press all the first moving contact pieces 8 against the outer side wall of the adjusting rod 15, all the first moving contact pieces 8 and the first static contact pieces 9 are separated and powered off.

[0056] Such as Figure 11 to Figure 18 As sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap