Preparation method for heat-not-burn cigarette core stick of rolling cigarette

A heat-not-burn, cigarette wick technology, applied in e-liquid filter, tobacco, application and other directions, can solve the problems of complex preparation and molding, difficulty in rolling and molding of high-viscosity tobacco media, insufficient sensory quality, etc., and achieve sensory quality improvement, Reduced opening and wrinkling steps, improved smoke consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of a dry-process reconstituted tobacco leaf of a heat-not-burn cigarette

[0025] Choose quantitative 115g / m 2 , the special reconstituted tobacco leaves for heat-not-burn cigarettes with a width of 11.0cm are respectively prepared into single sticks with a length of 120mm and a circumference of 24.0mm smoke core rod. In the preparation method of the present invention, the coiled shred width is 1.00mm, and the humidity environment for processing and molding is 40% relative humidity.

Embodiment 2

[0026] Example 2: Performance test of smoke core rod

[0027] Taking the two kinds of cigarette core rods in Example 1 (the control sample of the smoke core rod prepared by the conventional tobacco rod molding process and the smoke core rod prepared by the present invention) as the research objects, the performance comparison was carried out around the circumference, weight and draw resistance. The results are shown in Tables 1 and 2.

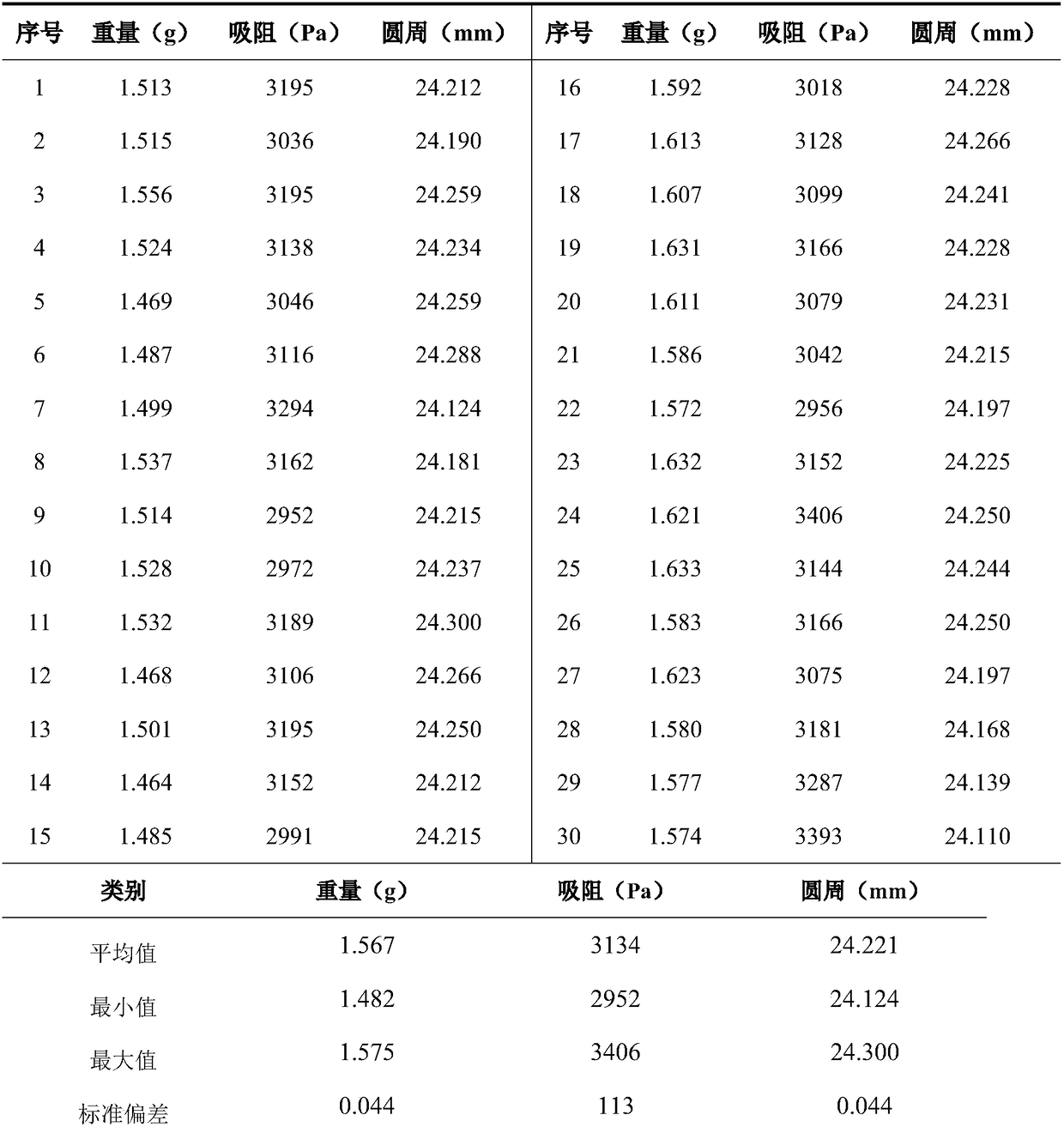

[0028] Table 1 control sample

[0029]

[0030]

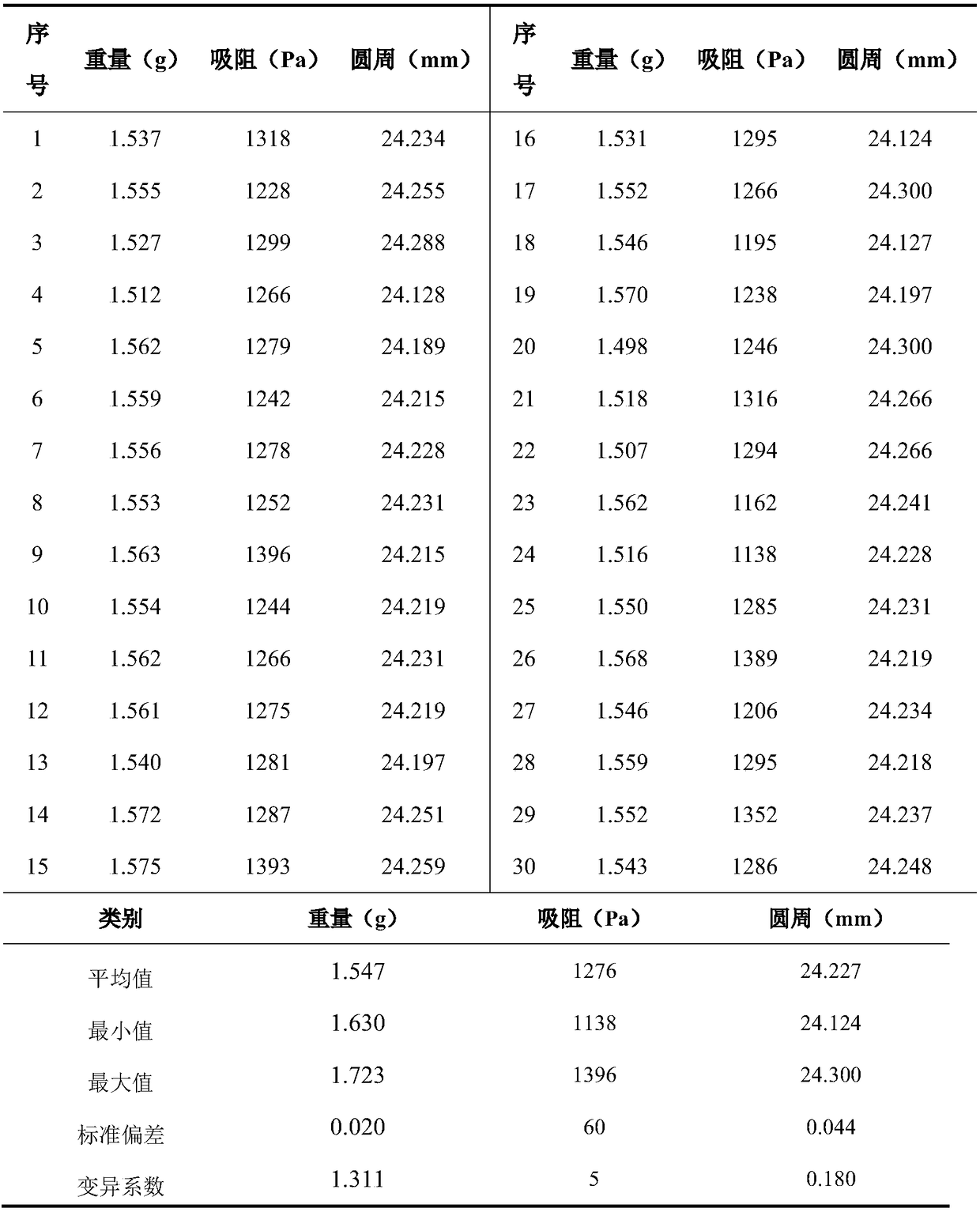

[0031] Table 2 The present invention

[0032]

[0033] As can be seen from Table 1 and Table 2, the reconstituted tobacco leaf product prepared by the preparation method of the present invention can better adapt to the processing requirements of the gathering process, and the physical index of the formed cigarette core rod is the same as that of the conventional one processed by the opening and wrinkling process. Compared with the physical indicators of the cigarette core rod made of ...

Embodiment 3

[0034] Embodiment 3: sensory quality evaluation method

[0035] Use two kinds of cigarette core rods in Example 1 respectively (the smoke core rod control sample prepared by the conventional tobacco core rod forming process and the smoke core rod prepared by the present invention) to prepare heat-not-burn cigarettes, and carry out according to the standards in Table 3 Sensory evaluation.

[0036] Table 3: Evaluation criteria for sensory quality of heat-not-burn cigarettes

[0037]

[0038] Inspection procedure: Provide samples and inspection forms to the evaluation experts, and require the evaluation staff to evaluate various indicators according to the requirements of the form.

[0039] Result statistics: The evaluation results of all appraisers are valid. Calculate the arithmetic mean of the individual evaluation results of each appraiser, keep the result to one decimal place, and add the arithmetic mean of each individual item to get the total score , the results are k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com