A kind of puffing method of wood and puffed wood prepared therefrom

A technology for wood and wood drying, which is applied in the field of puffing of wood and puffed wood, and can solve the problems of single puffed wood products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

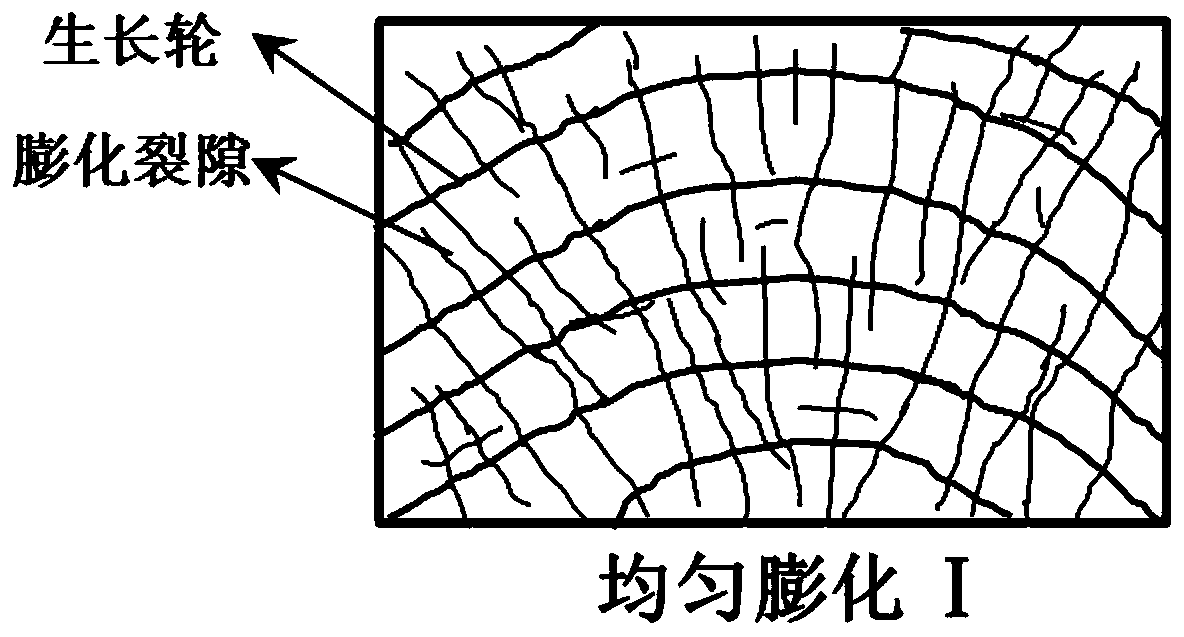

[0056] Example 1 Whole wood is uniformly expanded

[0057] Processing object: the sawn timber of Pinus sylvestris pine with a size of 22cm (width)*12cm (thickness)*200cm (length), with a moisture content of 40%.

[0058] Specific steps are as follows:

[0059] (1) Use a drying kiln to adjust the moisture content of the sylvestris pine sawn timber. Among them, the drying section: the dry bulb temperature is 55°C, the wet bulb temperature is 50°C, and the balance section: the dry and wet bulb temperature is 35°C, so that the whole sawn timber of the sylvestris pine The moisture content is controlled at 45%;

[0060] (2) Continuous tunnel microwave processing equipment (Nanjing Sanle Microwave Technology Development Co., Ltd., model WX100L, the same below) is used for microwave processing of wood. In order to obtain uniform puffed wood with different puffing degrees, 2 powers and 2 treatment time, the treatment process parameters are: microwave frequency 915MHz, microwave sourc...

Embodiment 2

[0063] Processing objects: sylvestris pine with a size of 22cm (width)*12cm (thickness)*200cm (length).

[0064] Specific steps:

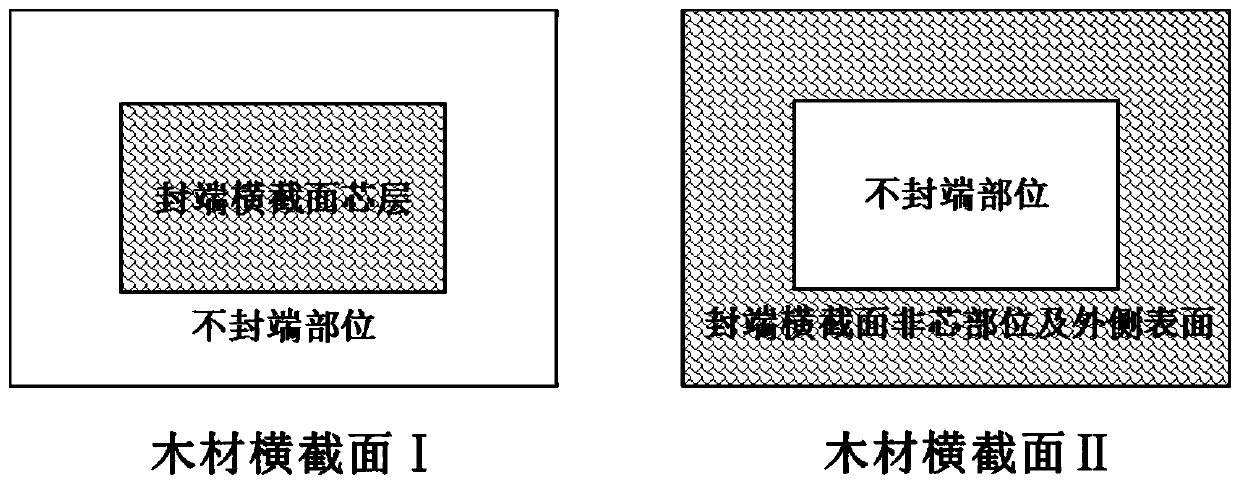

[0065] (1) if figure 1 I: The core layer of the green material is sealed with epoxy resin, and the amount of epoxy resin is 150g / m 2 ;

[0066] (2) The moisture content of the wood is adjusted by kiln drying. The dry bulb temperature of the drying section is 45°C, the wet bulb temperature is 40°C, and the dry and wet bulb temperature of the balance section is 35°C.

[0067] (3) Take out the board and use tunnel-type microwave equipment for wood puffing. The microwave power is 140kW, the cavity size is 15cm*30cm*50cm, and the conveyor belt speed is 1.5m / min. The wood moves with the conveyor belt and passes through the resonant cavity. Expansion treatment to obtain expanded wood.

Embodiment 3

[0069] Processing object: the size is 22cm (width) * 12cm (thickness) * 200cm (length) of sylvestris pine wood, and the wood moisture content is 10%.

[0070] Specific steps:

[0071] (1) Use epoxy resin to completely seal the cross-section core of Pinus sylvestris, and the resin dosage is 150g / m 2 , then soak the sealed wood in water at normal temperature for 24 hours, adjust the moisture content of the wood surface to about 50%, and the moisture content of the core layer to be below 20%;

[0072] (3) Take out the board and use tunnel-type microwave equipment for wood puffing. The microwave power is 140kW, the cavity size is 15cm*30cm*50cm, and the conveyor belt speed is 1m / min. The wood moves with the conveyor belt and the wood puffing is completed after passing through the resonant cavity. Processing to obtain expanded wood.

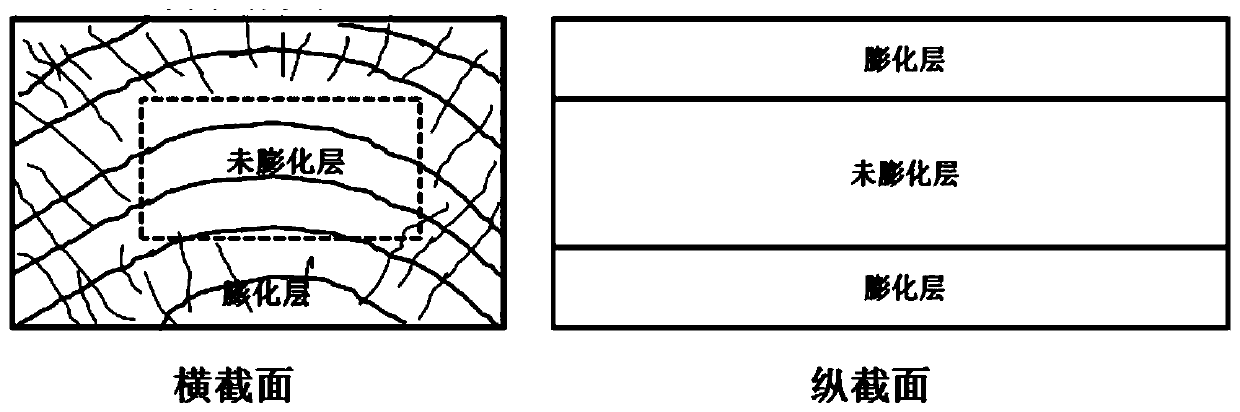

[0073] By observing and measuring the end face of the expanded wood with the naked eye and soft X-ray, it was found that the upper and lower surfaces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com