Performance test device for visual packer rubber cartridge

A test device and packer technology, applied in the field of exploration, can solve the problems of no anti-retraction mechanism, no accurate test of the setting distance of the rubber tube, and the inability to display the influence of the retreat amount and sealing pressure, so as to achieve accurate measurement The effect of the operation

Active Publication Date: 2020-05-22

CHINA NAT OFFSHORE OIL CORP +1

View PDF10 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the performance testing device of the packer in the prior art only includes a setting mechanism and a seal inspection mechanism, and does not accurately test the setting distance of the rubber sleeve, and the performance of the sealing annulus of the rubber sleeve depends on the setting force The change of the setting distance caused by it is positively correlated with the setting distance

At the same time, the single rubber cartridge performance test device does not have an anti-retraction mechanism, cannot display the influence of the retraction amount on the sealing pressure, and cannot completely simulate the sealing performance of the downhole packer and the rubber cartridge fatigue test under real conditions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

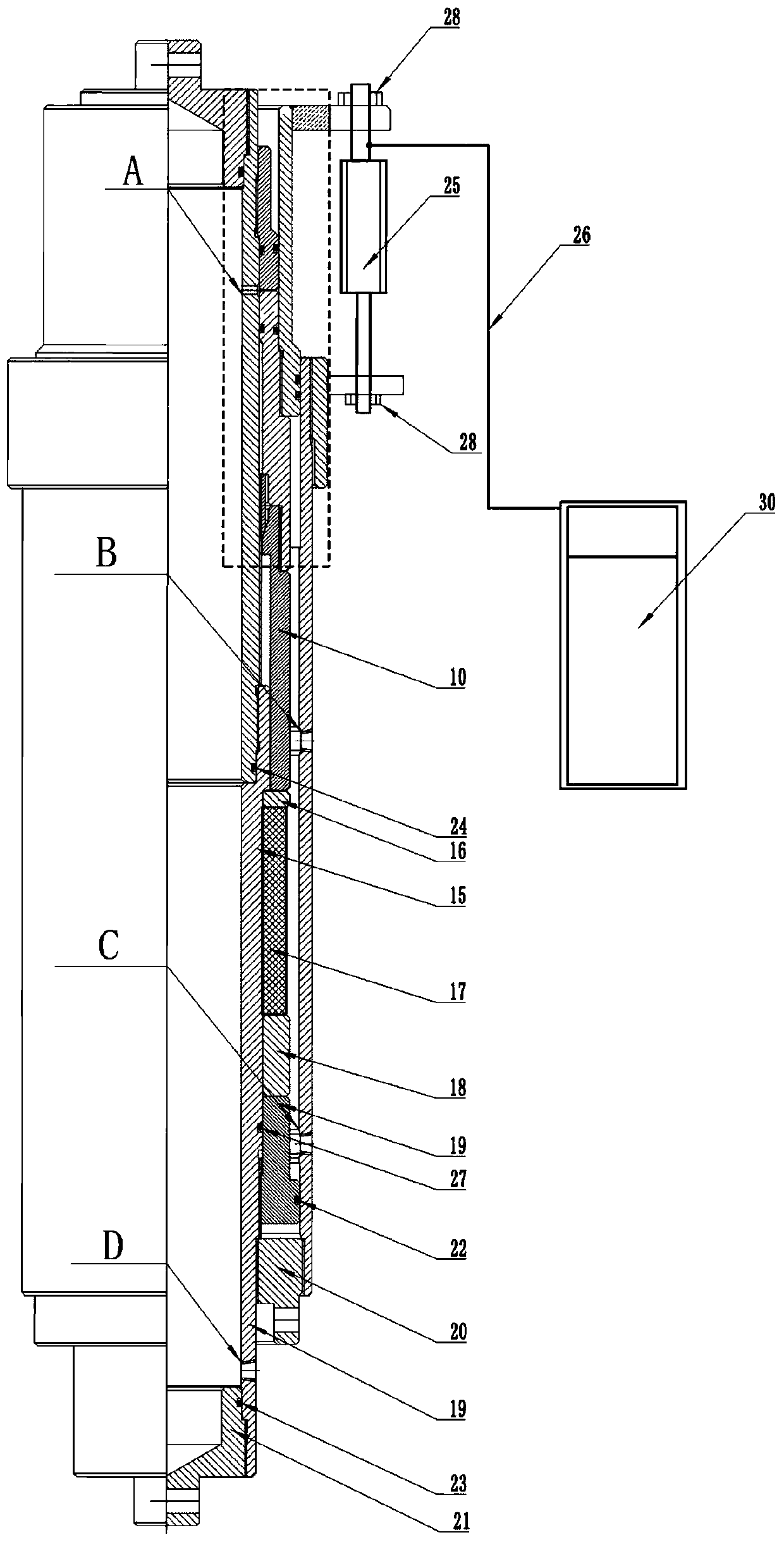

[0043] combine figure 1 As shown, Embodiment 1 of the present invention provides a performance testing device for a visual packer rubber cartridge, including a packer assembly and a test assembly;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a performance testing device for a visual rubber packer, which comprises a packer assembly, a test assembly and a display; wherein the testing assembly is connected with the packer assembly and comprises a displacement sensor and a control circuit. The displacement sensor is used for detecting the displacement of the rubber packer and generating a corresponding detection signal; and the control circuit is used for receiving the detection signals, the control circuit is connected with the display, and the display is used for displaying the specific numerical value of thesetting distance and the back-off distance of the rubber packer.

Description

technical field [0001] This application relates to but not limited to the field of exploration technology, especially a performance testing device for visual packer rubber cartridges. Background technique [0002] A packer is a downhole operation tool that seals the annulus with a sealing element rubber tube and isolates the production layer to control fluid production or injection and protect the casing. At present, compression packers have a wide range of applications, whether in drilling, exploration or completion processes. Its working principle: Under the action of axial force, the pressure sleeve at one end of the rubber tube produces axial displacement and compresses the rubber tube, making it radially expand and fit the inner wall of the casing, so as to seal the annular gap and prevent liquid leakage. Purpose. [0003] As a key downhole tool, its main component, the rubber cartridge, must undergo strict performance testing before entering the well to ensure that t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M13/00

CPCG01M13/00

Inventor 程文佳高彦才谢涛饶志华董社霞李英松梁月松王东刘明娟

Owner CHINA NAT OFFSHORE OIL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com