Laser welding equipment

A technology of laser welding and equipment, applied in laser welding equipment, welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

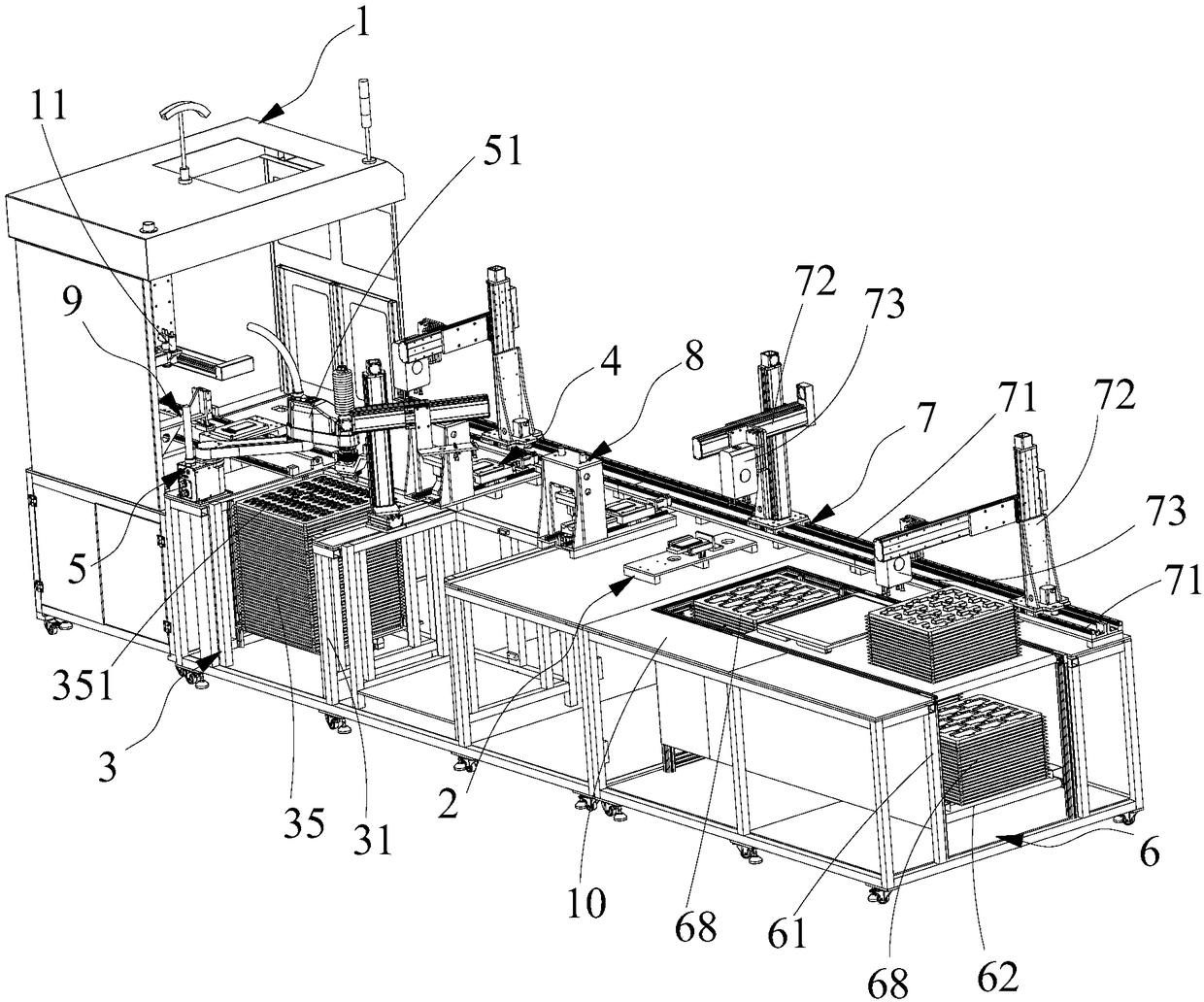

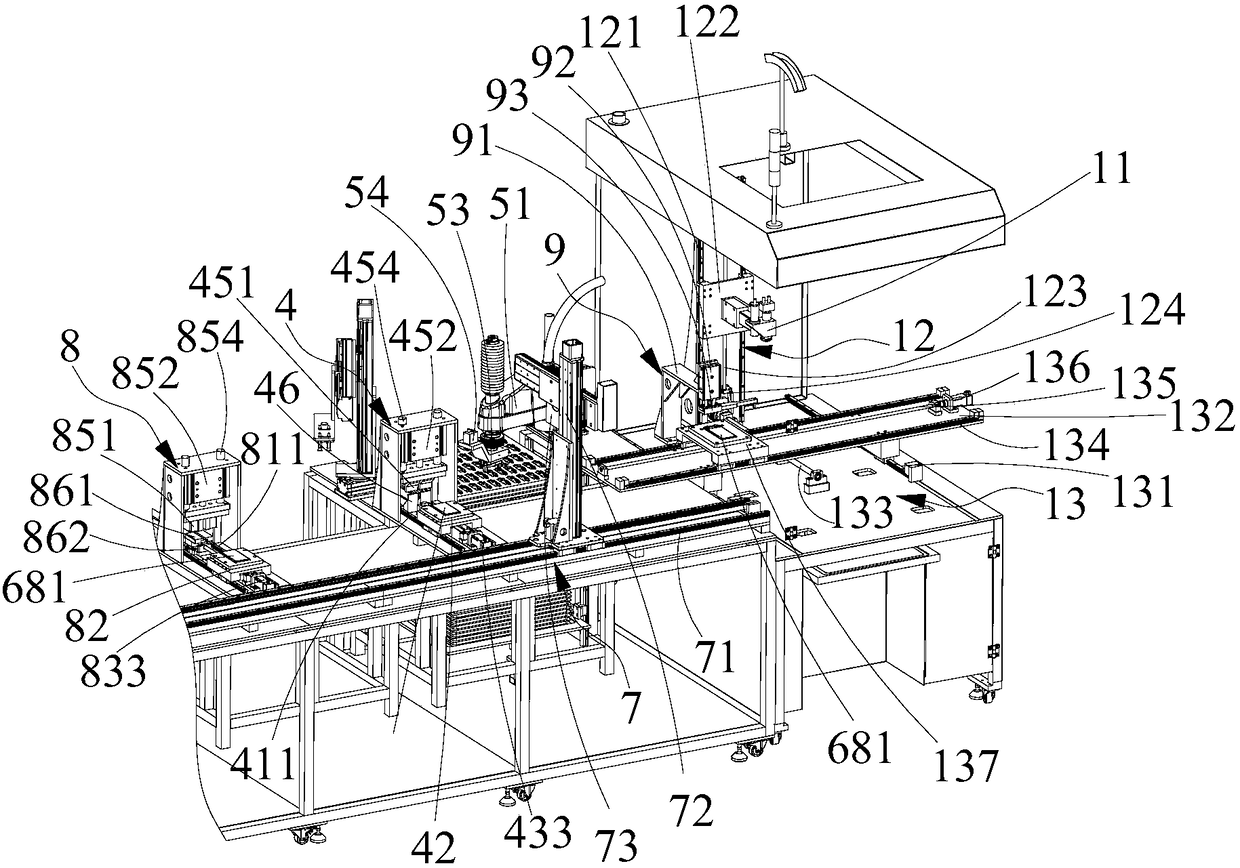

[0045] Further, see Figure 1-Figure 2 and Figure 4 As a specific implementation of the laser welding equipment provided by the present invention, the plate transfer device 5 includes a plate transfer manipulator 51, and a plate loading connecting plate 52 connected to the output end of the plate transfer manipulator 51 , The plate pneumatic finger 53 provided on the plate feeding connecting plate 52, and the CCD sensor 54 provided on the plate feeding connecting plate 52; the plate feeding device 3 includes the The plate supporting frame 31 connected to the platform 10, the plate loading lifting plate 32 slidably connected to the plate supporting frame 31 and used for placing the plate material tray 35, and used to drive the plate loading The lifting plate 32 moves up and down the plate feeding and lifting driving device. The plate feeding and lifting drive device includes a plate feeding screw nut connected to the plate feeding lifting plate 32, and a plate feeding screw sha...

specific Embodiment approach

[0049] Further, see figure 2 As a specific implementation of the laser welding equipment provided by the present invention, the carrier drive mechanism 13 includes a first carrier slide 131, and a carrier slide 132 slidably connected to the first carrier slide 131 , A first carrier screw nut connected to the carrier sliding seat 132, a first carrier screw shaft 133 matched with the first carrier screw nut, for driving the first carrier The first carrier drive motor rotated by the screw shaft 133, the second carrier slide 134 provided on the carrier slide 132, the second carrier screw nut connected to the welding carrier 137, and The second carrier screw shaft 135 matched with the second carrier screw nut, and the second carrier drive motor 136 for driving the second carrier screw shaft 135 to rotate; the welding carrier 137 It is slidably connected to the second carrier rail 134, and the first carrier rail 131 and the second carrier rail 134 are perpendicular to each other. T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap