Automobile connector used for fixing lead

A plug-in and automobile technology, applied in the direction of vehicle components, electrical components, circuits or fluid pipelines, etc., can solve the problems of potential safety hazards, easy shaking, lack of fixation, etc., and achieve the effect of reducing force, reducing shaking, and effective protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

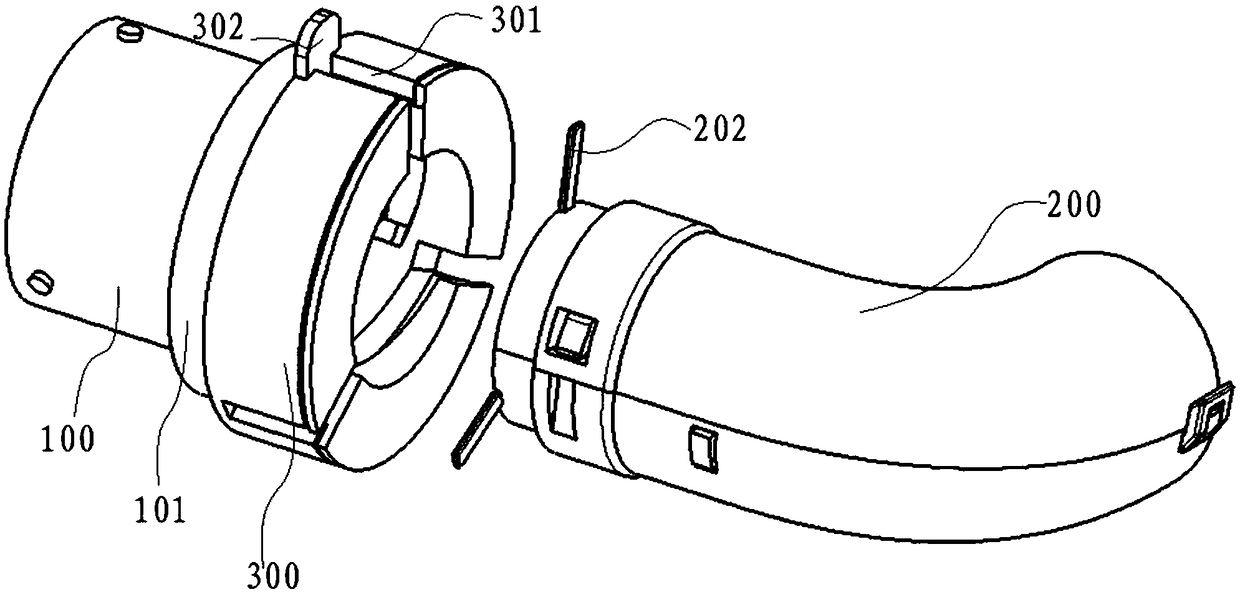

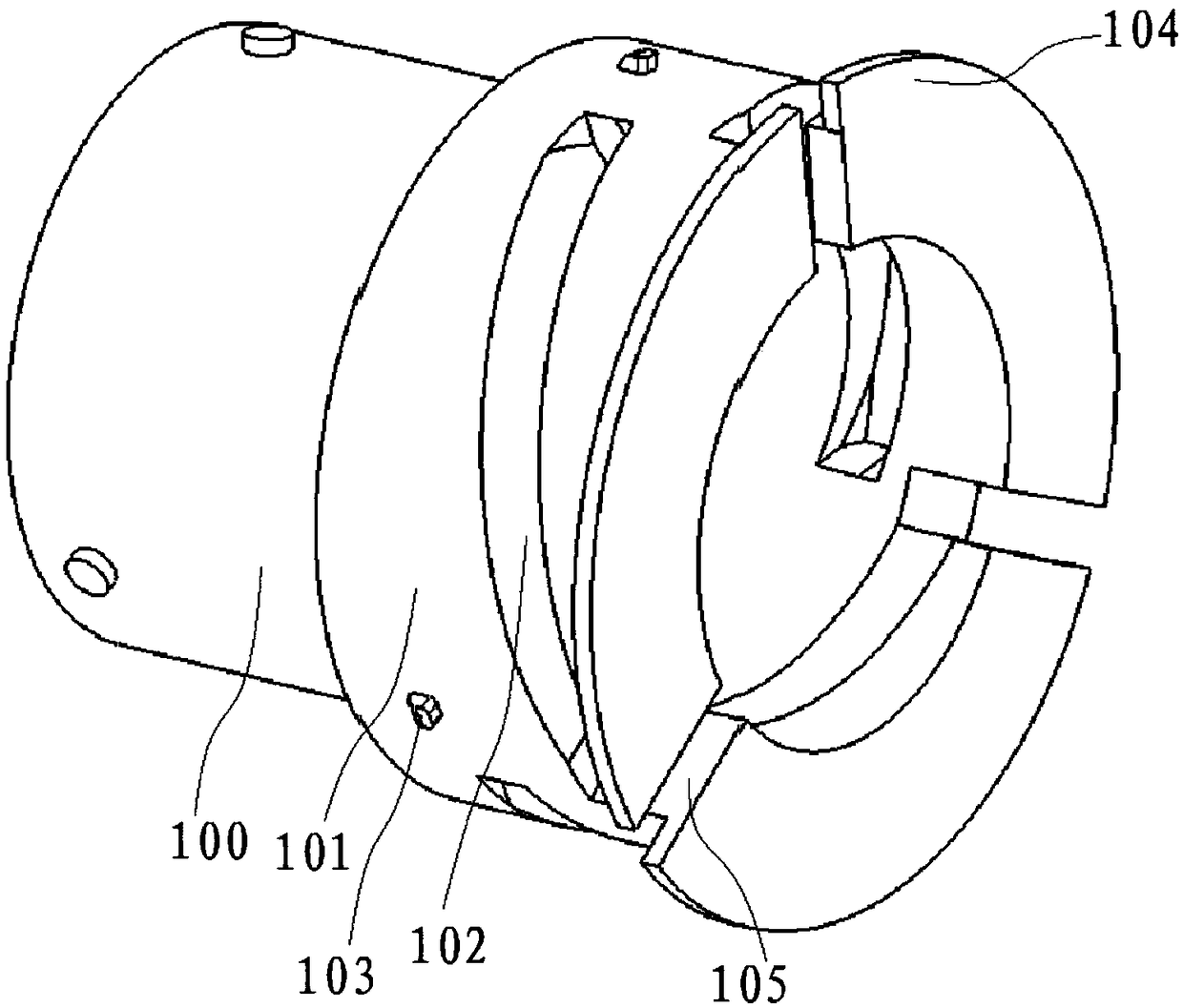

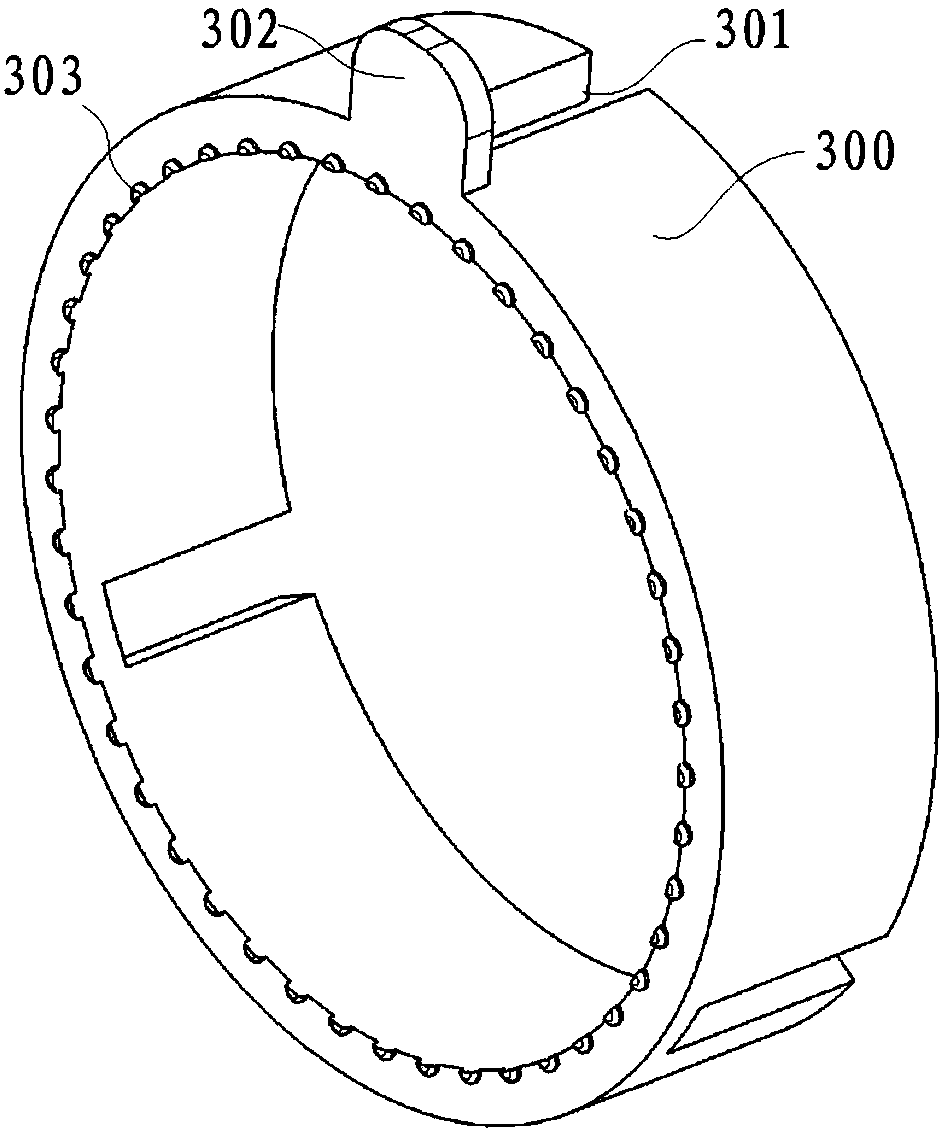

[0039] like figure 1 , Figure 4 , Figure 7 and Figure 8 As shown, the embodiment of the present invention provides a kind of automobile plug-in for fixing wire, comprises:

[0040] The plug-in body 100, the appearance of the plug-in body 100 is a cylinder commonly used in the prior art, and the plug-in body 100 is provided with a number of wire holes in the axial direction.

[0041] The back cover 200 is fixedly connected to the plug-in body 100. The shape of the back cover 200 is a bent tubular structure. The back cover 200 is axially penetrated with a passageway 201, so that the tail wire 500 of the plug-in body 100 is realized. effective protection.

[0042] The elastic pressing part 400 includes a base 401, a spring 402 and a moving part 403. The base 401 is a flat semicircular st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com