Air chamber cover and vehicle

An air chamber and cover plate technology, which is applied in the field of vehicles, can solve the problems of difficult filling of brake pots and washing pots, and water leakage at the sealing connection position, so as to achieve the effect of convenient filling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

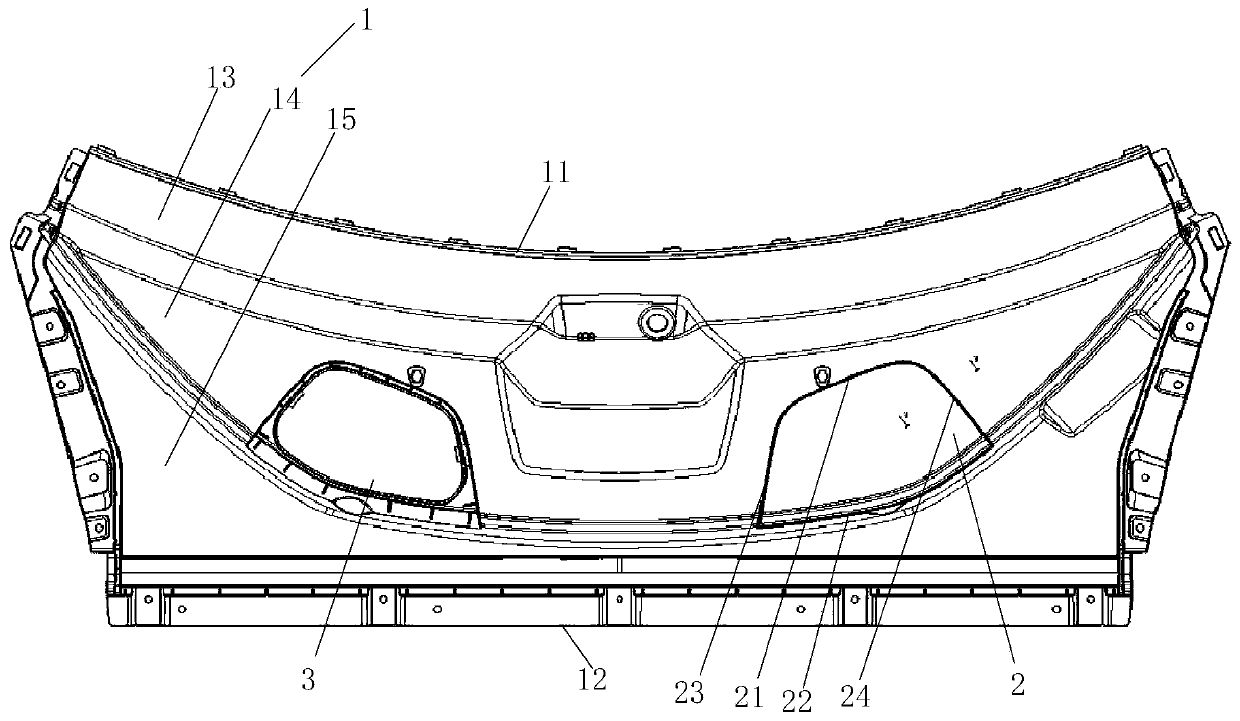

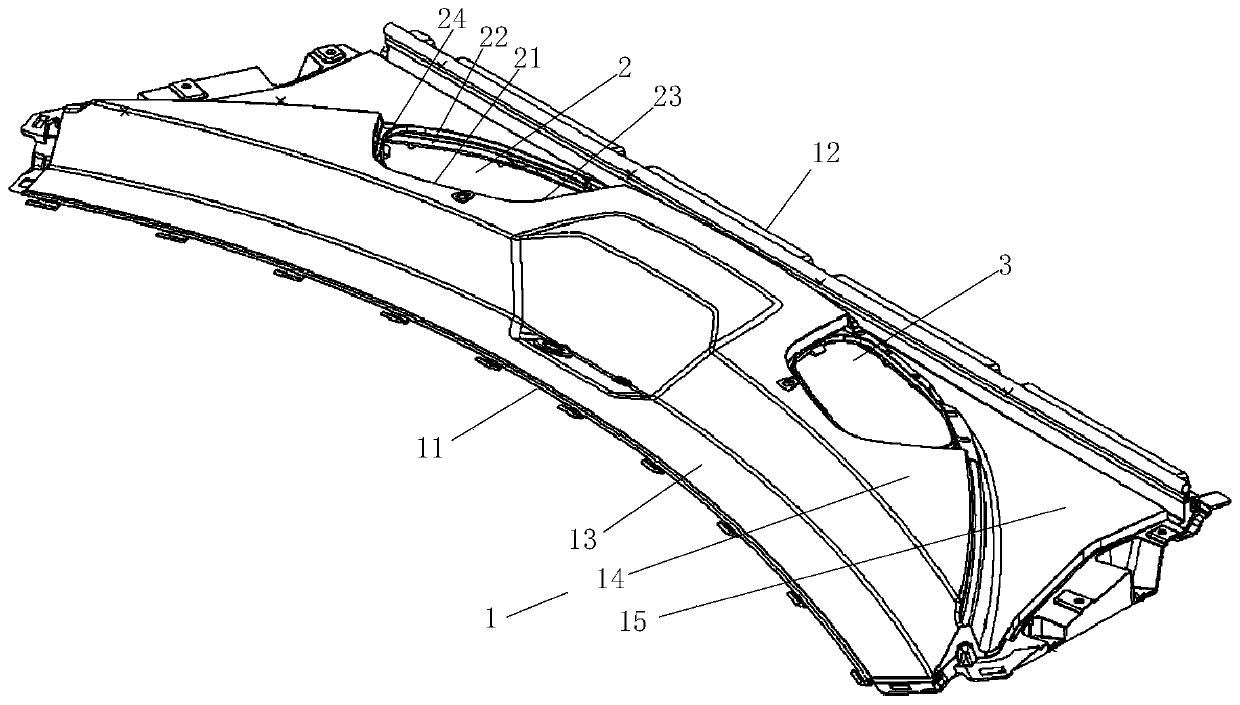

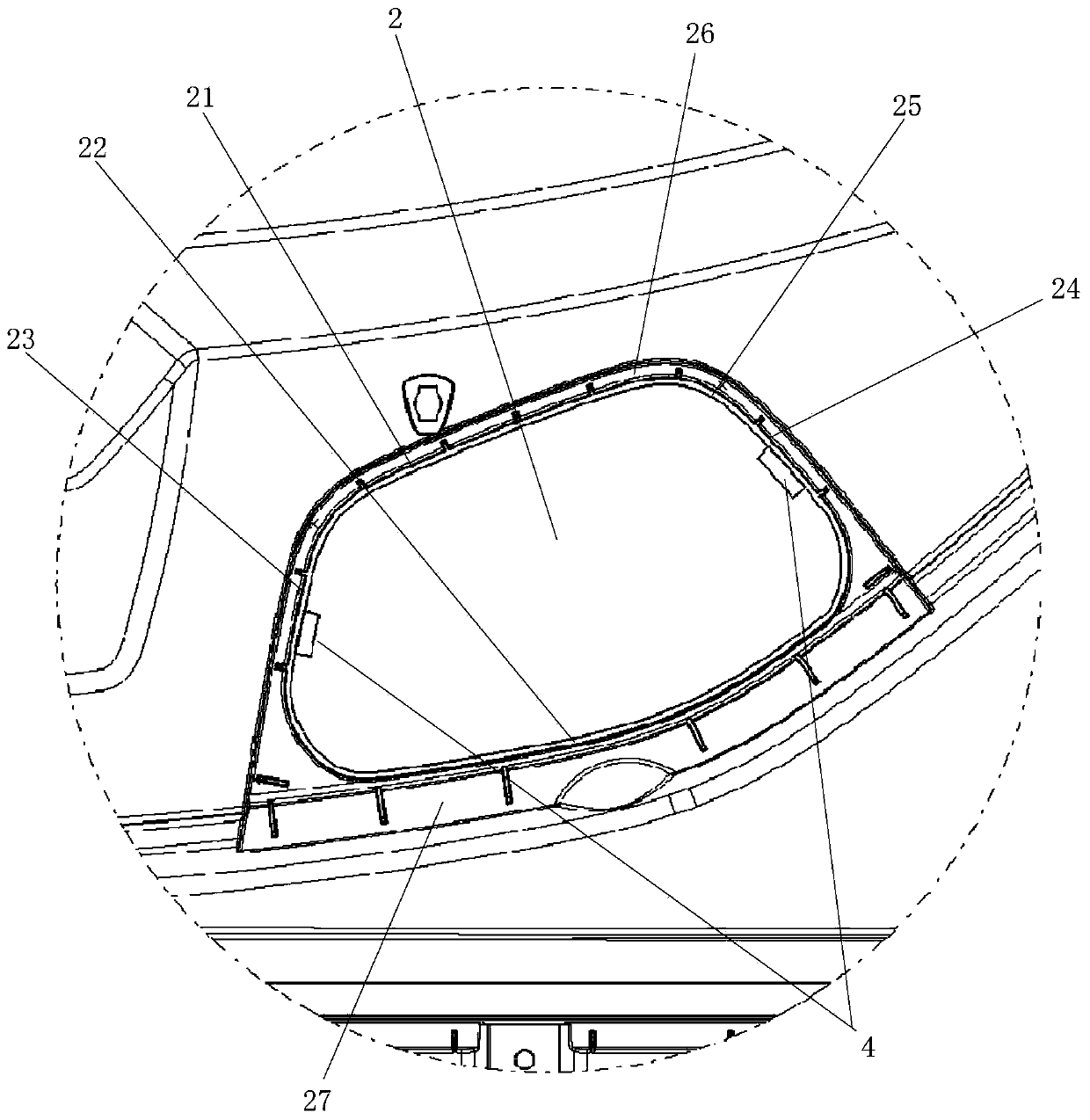

[0045] Such as figure 1 with figure 2 As shown, the first embodiment of the present invention proposes an air chamber cover, which includes: a body 1, a first window 2 and a second window 3; the first window 2 and the second window 3 are arranged at intervals on the On the body 1; wherein, the first window 2 is used to reveal the filling port of the brake pot, and the second window 3 is used to reveal the filling port of the washing pot.

[0046]Specifically, the air chamber cover is an important part arranged between the front windshield glass and the front cabin cover of the vehicle. , and it also needs to have the function of draining water, preventing sundries from entering the air conditioner and the front cabin, etc. The body is the main part of the air chamber cover, including the above-mentioned connecting structures for connecting with the strong windshield glass and the front cabin cover, the structure for draining water, the first window and the second window for...

Embodiment 2

[0067] Embodiment 2 of the present invention proposes a vehicle, which includes: an air chamber cover plate; the air chamber cover plate includes: a body 1, a first window 2 and a second window 3; the first window 2 and the second window The windows 3 are arranged on the body 1 at intervals; wherein, the first window 2 is used to reveal the filling port of the brake pot, and the second window 3 is used to reveal the filling port of the washing pot.

[0068] Specifically, the air chamber cover described in Embodiment 2 can directly use the air chamber cover provided in Embodiment 1 above. For the specific implementation structure, please refer to the relevant content described in Embodiment 1 above, and will not repeat them here. .

[0069]In the technical solution of the present invention, the air chamber cover is provided with a first window and a second window. When the air chamber cover is installed on the vehicle, the first window can reveal the filling port of the brake p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com