Controller for electric vehicle

A technology for electric vehicle controllers and circuit boards, applied in the direction of electrical components, electrical equipment shells/cabinets/drawers, etc., can solve the problem of not being able to achieve a satisfactory sealing and waterproof effect, not having rework, repair, maintenance performance, profiles There are gaps between the end face and the rubber pad to achieve good sealing and waterproof effects, saving processes and avoiding water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

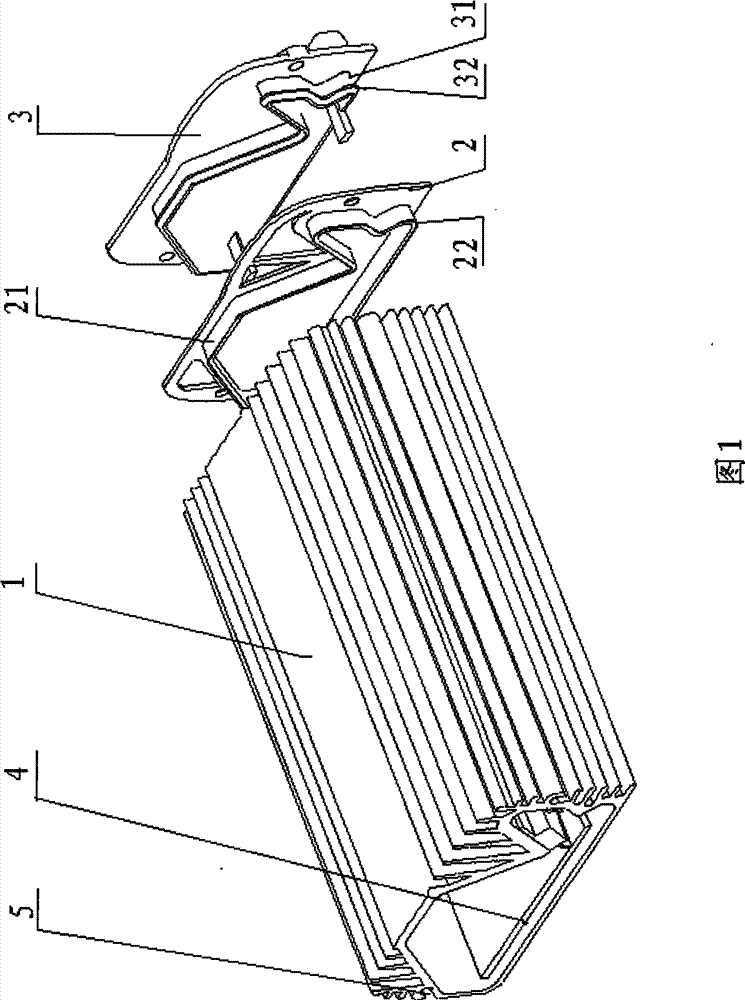

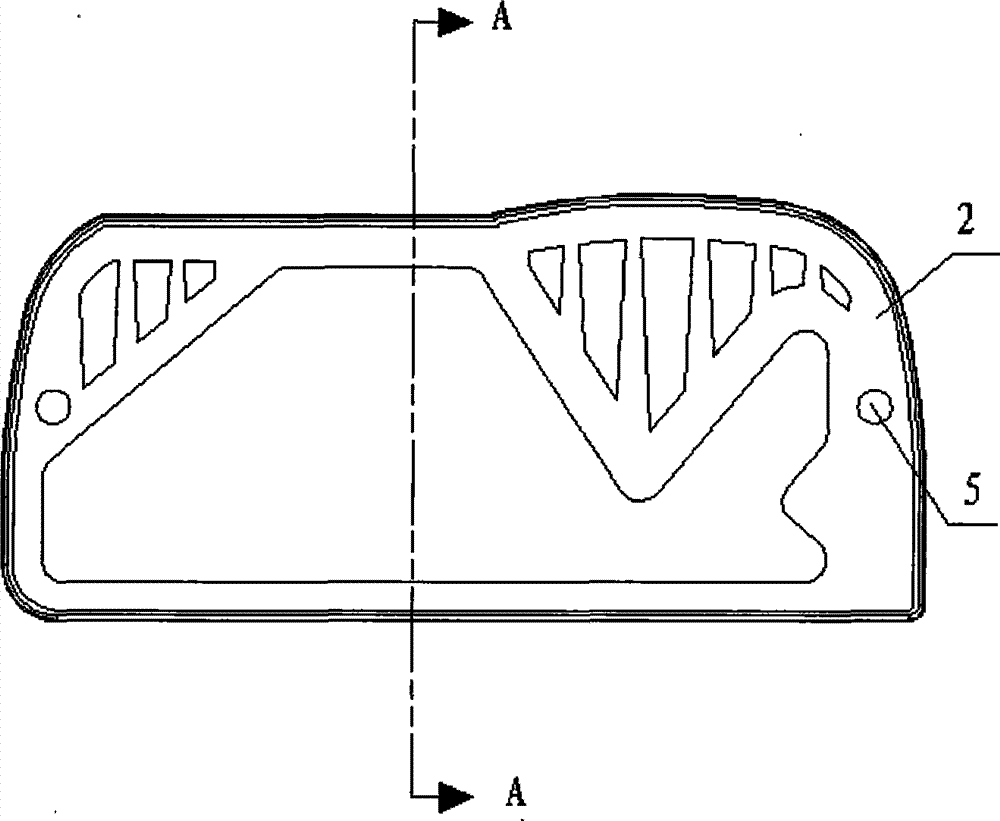

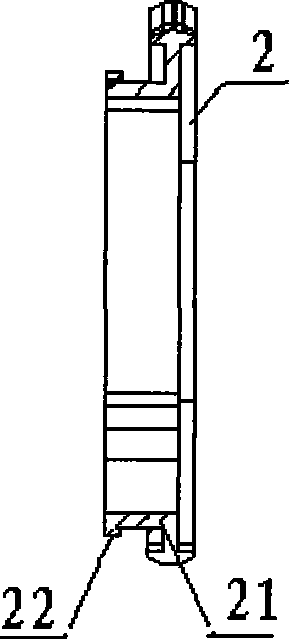

[0024] Such as figure 1 -As shown in 6, 1—housing; 2—inner pad; 21—rib; 22—convex; 3—outer cover; 31—rib; 32—protrusion; 4—circuit board; 5—screw hole; 6—fastener; 7—opening piece; 8—buckle.

[0025] The technical scheme of the present invention is as follows: the electric vehicle controller of the present invention comprises a cavity type housing 1, a circuit board 4 arranged in the housing 1 and an end cover 3 arranged at the outer end of the housing, the housing 1 and the An inner pad 2 is arranged between the end covers 3, and an inwardly protruding annular rib 21 is arranged on the inner pad 2, and the rib 21 is closely matched with the surface of the inner cavity of the housing. The cover 3 is provided with an inwardly protruding annular rib 31 , the rib 31 is embedded in the inner surface of the rib 21 , and the rib 31 supports the rib 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com