A cosmetic composition comprising α-mangostin, its preparation method and its use

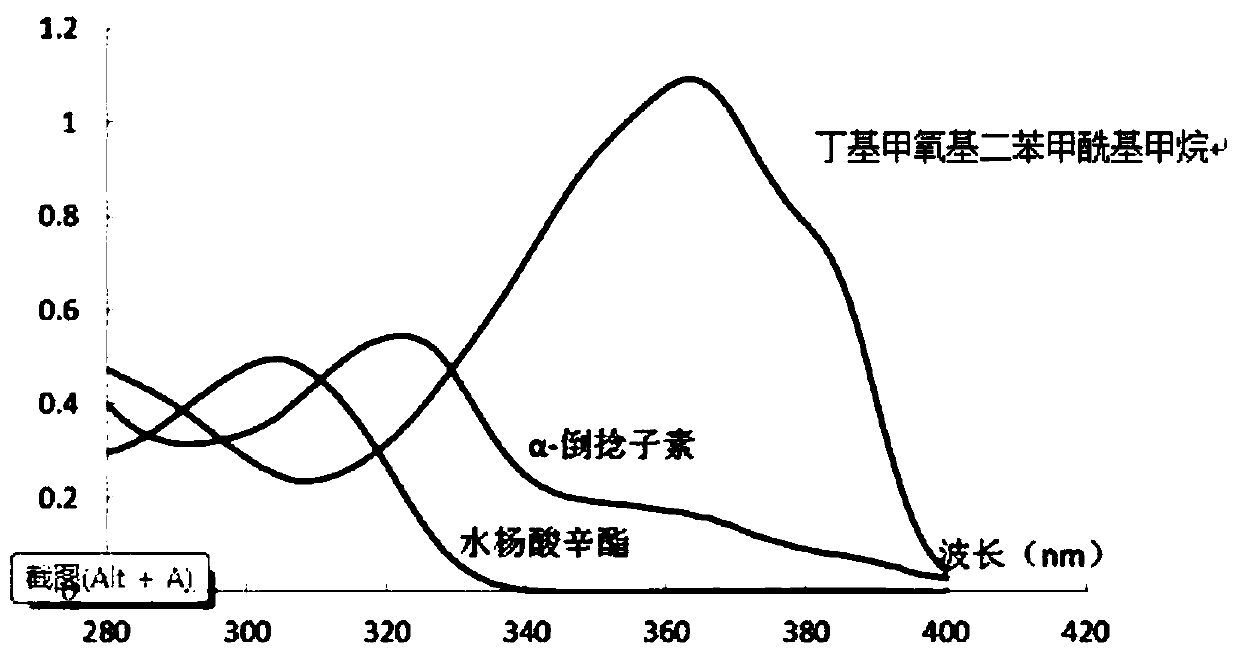

A cosmetic composition, mangostin technology, applied in sunscreen or whitening cosmetic composition, cosmetic composition field, can solve the problems of new technology safety, narrow ultraviolet absorption band, lack of new sunscreen, etc., to achieve enhanced photostability Strong solubility and high SPF value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The present embodiment is control sample 1, and its composition is as follows table 1:

[0051]

[0052]

[0053] Table 1

[0054] Preparation process: according to the amounts shown in Table 1, respectively weigh vaseline, lanolin, stearic acid and liquid paraffin to mix to obtain an oil phase; weigh SE-11, glycerin and water, and mix them evenly to obtain an aqueous phase; weigh Carbomer 980, and slowly added to the high-speed stirring water, the gel phase was obtained after the dissolution was complete; α-mangostin was weighed and mixed with methylparaben, and the mixture was dissolved in ethanol.

[0055] Heat the oil phase and water at the same time until the oil phase is completely dissolved (about 80°C), add the water phase to the oil phase under isothermal conditions and keep grinding and stop heating. After grinding to close to room temperature, add the gel phase and continue grinding , adding an ethanol solution in which α-mangostin and methylparaben we...

Embodiment 2

[0057] This embodiment is sample 2 under one of the implementation modes of the present invention, and its components are as follows in Table 2:

[0058]

[0059] Table 2

[0060] Preparation process: According to the dosage shown in Table 2, respectively weigh vaseline, lanolin, stearic acid and liquid paraffin and mix to obtain an oil phase; weigh SE-11, glycerin and water, and mix them evenly to obtain an aqueous phase; weigh Carbomer 980, and slowly added to the high-speed stirring water, the gel phase was obtained after the dissolution was complete; α-mangostin was weighed and mixed with methylparaben, and the mixture was dissolved in ethanol.

[0061] Heat the oil phase and water at the same time until the oil phase is completely dissolved (about 80°C), add the water phase to the oil phase under isothermal conditions and keep grinding and stop heating. After grinding to close to room temperature, add the gel phase and continue grinding , add the ethanol solution that...

Embodiment 3

[0063] This embodiment is sample 3, and it is compared with embodiment 2, does not contain α-mangostin, and component is as follows table 3:

[0064]

[0065] table 3

[0066] Preparation process: According to the dosage shown in Table 3, respectively weigh vaseline, lanolin, stearic acid and liquid paraffin and mix to obtain the oil phase; weigh SE-11, glycerin and water, and mix them evenly to obtain the water phase; weigh Carbomer 980, and slowly added to the high-speed stirring water, the gel phase was obtained after complete dissolution; weighed methyl paraben and dissolved in ethanol.

[0067] Heat the oil phase and water at the same time until the oil phase is completely dissolved (about 80°C), add the water phase to the oil phase under isothermal conditions and keep grinding and stop heating. After grinding to close to room temperature, add the gel phase and continue grinding , adding an ethanol solution in which methylparaben was dissolved, and grinding evenly, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com