Pile body defect detection method

A defect detection and pile body technology, which is applied in the test of basic structure, construction, basic structure engineering, etc., can solve the problems of complicated detection process and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to illustrate the technical solution of the present invention more clearly, the present invention will be briefly introduced below using examples. Obviously, what is described below is only an embodiment of the present invention. For those of ordinary skill in the art, On the premise of paying creative efforts, other technical solutions can also be obtained according to these embodiments, which also belong to the disclosure scope of the present invention.

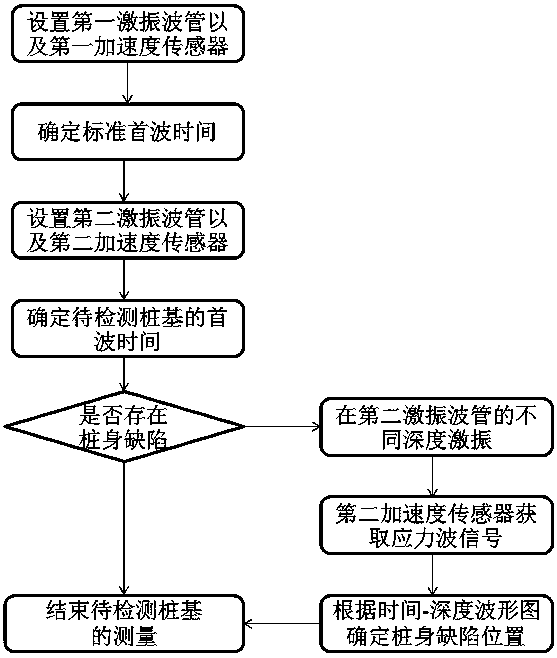

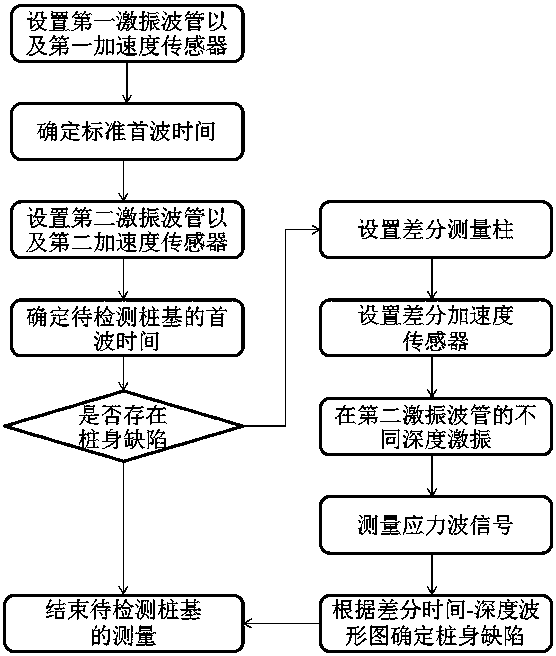

[0024] For the pile body defect detection method of the first embodiment of the present invention, see figure 1 , including the following steps: (1) setting the first vibration tube in the soil around the pile without defects, and setting the first acceleration sensor on the side wall of the top of the pile foundation; (2) placing the excitation source in the first excitation The bottom of the vibration tube is excited, and the first acceleration sensor is used to detect the time Tf when the first wave of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com