Piercing wire connector live working wire-connecting apparatus and branch wire clamping apparatus thereof

A clamping device and branch line technology, applied in the direction of conductive connection, clip connection conductor connection, circuit, etc., can solve the problems of different clamping force of lead wires, large conductive range, easy detachment of thin wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0045] Figure 1 to Figure 15 Some embodiments according to the invention are shown.

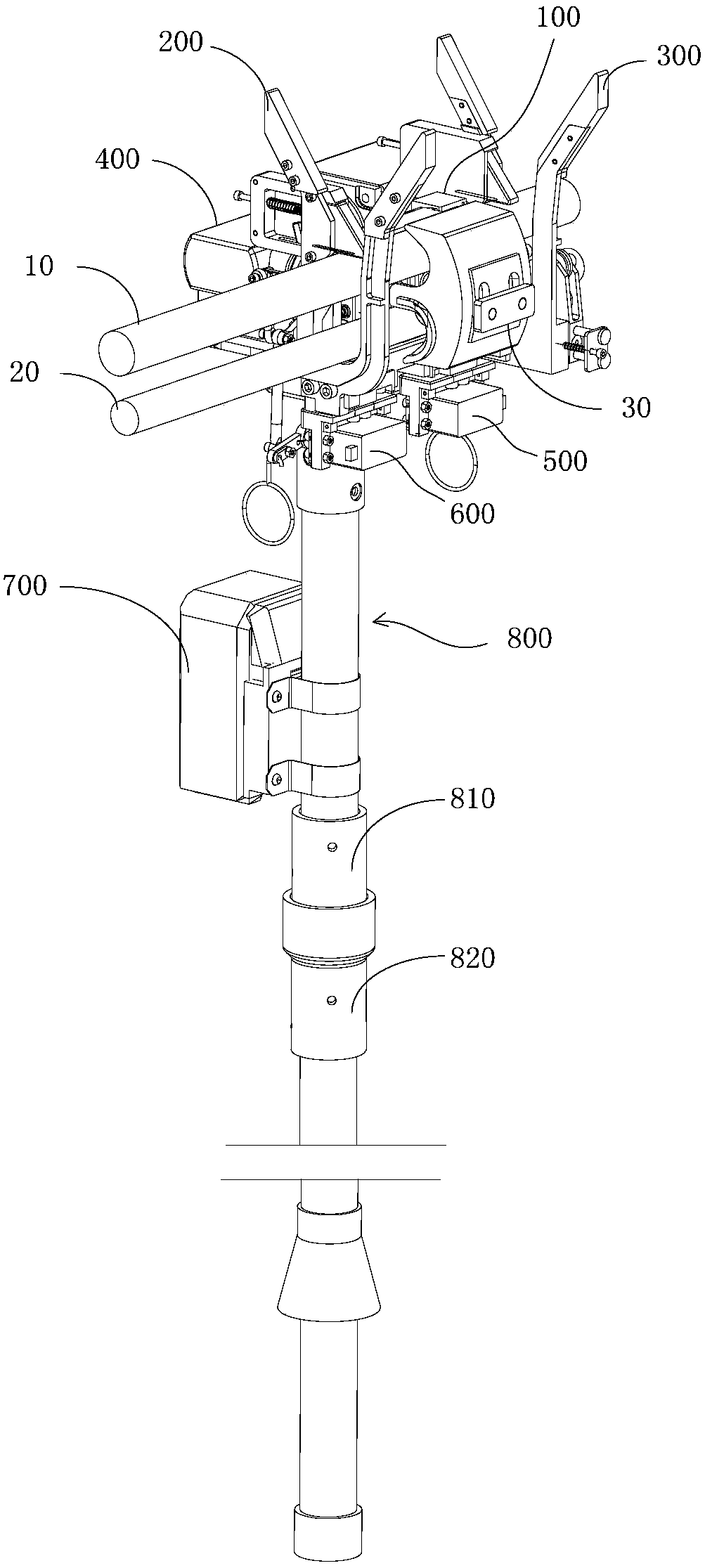

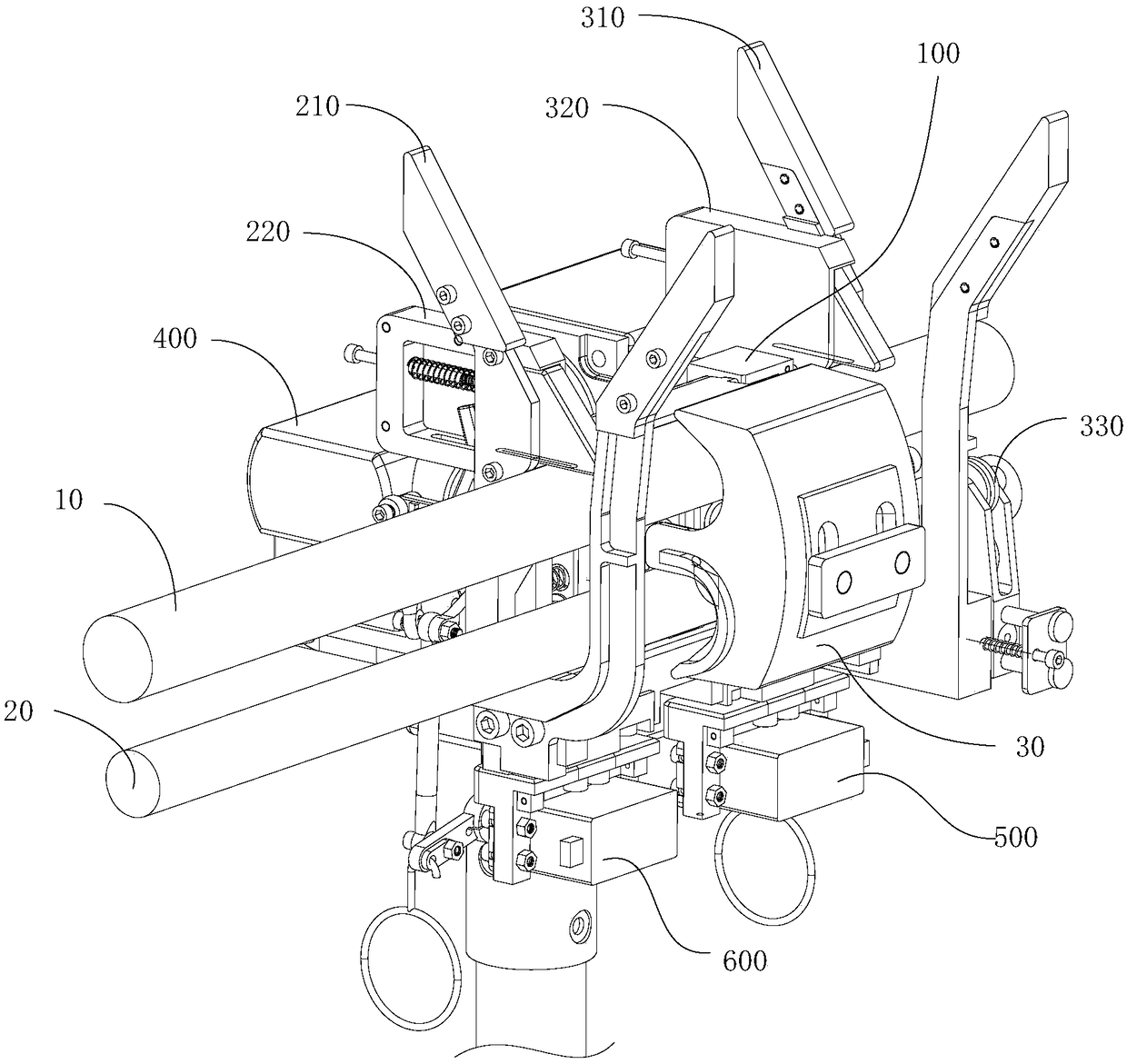

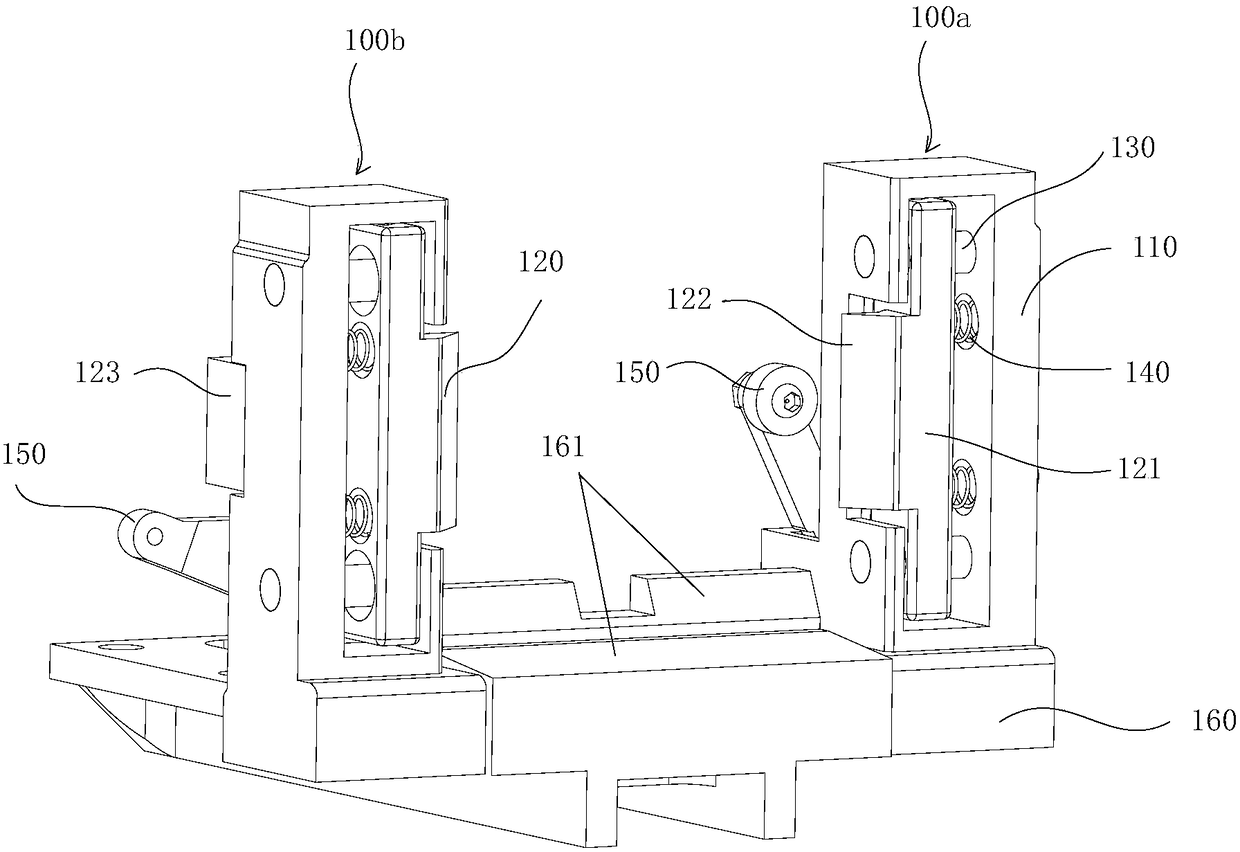

[0046] Such as figure 1 and figure 2 As shown, the live fire contacting device includes a clamp holding device 100, a left wire clamp frame 200, a right wire clamp frame 300, a branch wire clamp device 330, a striking device 400, a first steering gear 500, a second steering gear 600, A battery box 700, and an insulating rod 800.

[0047] The live ignition device is used to operate the puncture wire clip 30 to electrically connect the branch wire 20 (or called lead wire) to the main lead 10, and then the live fire connection device breaks away from the puncture wire clip, and as a result, the puncture wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com