Modular coupling structure with sound insulation, sound absorption and sound diffusion functions

A modular and structural technology, applied in the direction of sound insulation, building components, indoor acoustics, etc., can solve the problems of high maintenance costs, difficult to meet the requirements of the sound field environment, and complicated decoration, so as to save manpower, material resources and time costs, The effect of shortening the time in the acoustic environment and avoiding harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

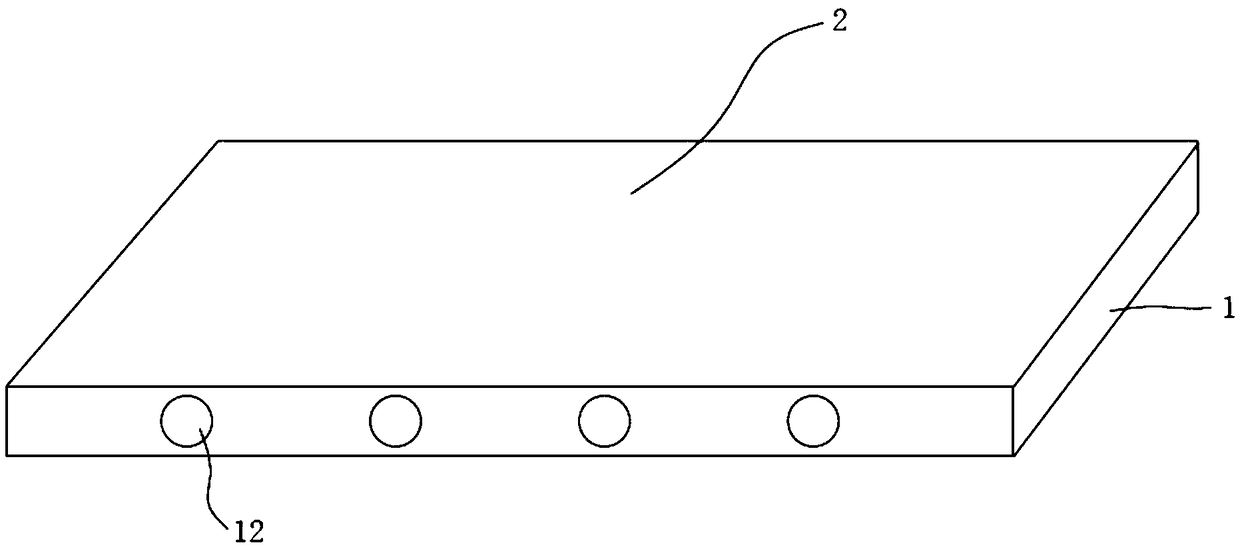

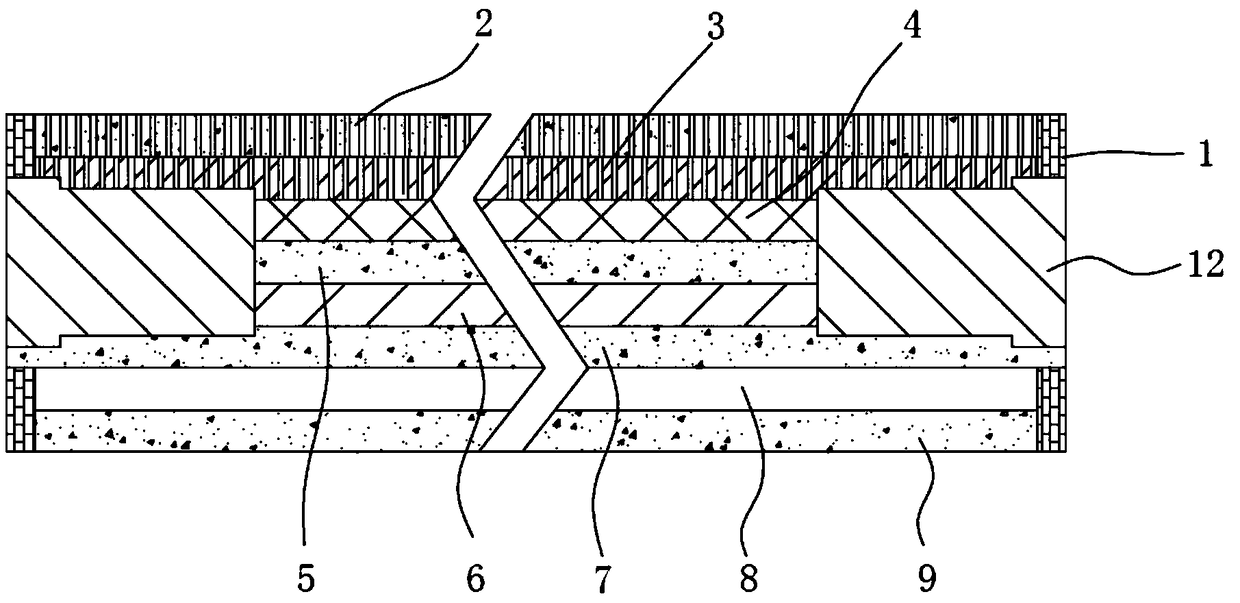

[0043] refer to Figure 1 to Figure 3 , this embodiment provides a modular coupling structure with sound insulation, sound absorption, and sound diffusion functions, which includes a frame body 1 with an upper opening and a lower opening, and the frame body 1 is installed sequentially from top to bottom. Perforated sound-absorbing material board 2, perforated flame-retardant board 3, porous sound-absorbing material board I4, gypsum board 5, porous sound-absorbing material board II6, wooden material board 7 and aluminum buckle board 9.

[0044] In this embodiment, the frame body 1 is preferably a rectangular structure, so as to be easily installed on the wall and spliced with each other, and its material is metal or wooden; the perforated sound-absorbing material board 2 is uniform A number of small holes are opened; the perforated flame-retardant plate 3 is a number of small holes evenly opened on the flame-retardant plate; the porous sound-absorbing material plate I4 and th...

Embodiment 2

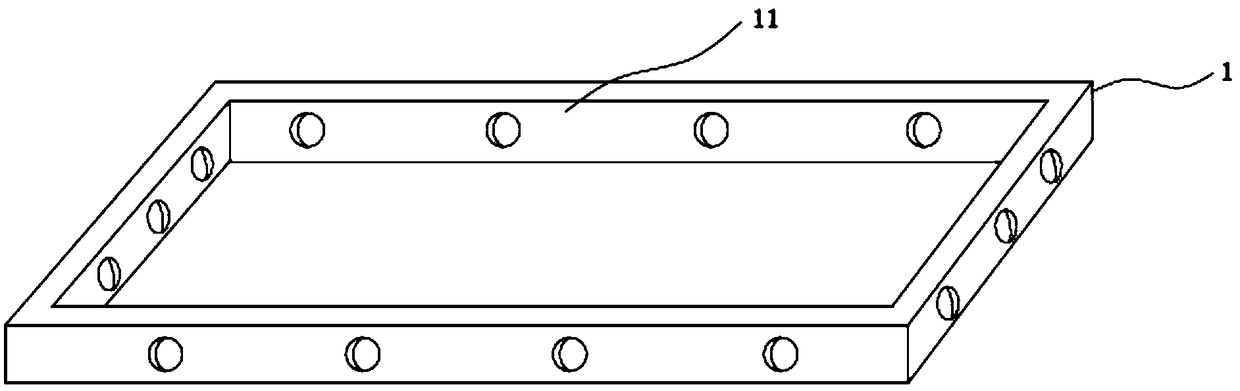

[0060] This embodiment is further optimized based on Embodiment 1. The optimization lies in the structure of the frame body 1. For details, refer to Figure 4 In this embodiment, ribs 13 and grooves 14 are respectively provided on opposite sides of the frame 1, and the ribs 13 of one frame 1 are set in cooperation with the grooves 14 of the other frame 1, so as to ensure that two adjacent The sealing effect when a modular coupling structure is assembled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com