Paper cropping device

A cutting and paper technology, applied in the cutting field, can solve the problems of affecting paper winding, uneven surface of transfer roller, production loss and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

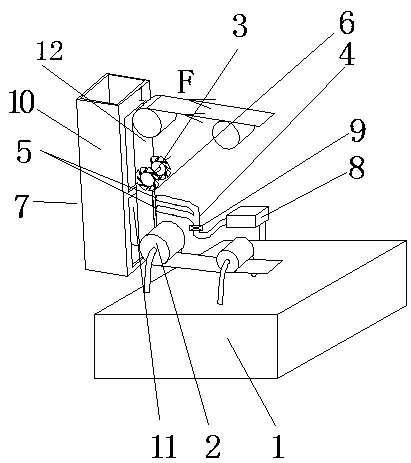

[0015] The present invention will be further described below in conjunction with the accompanying drawings

[0016] like figure 1 As shown, the paper cutting device includes a frame 1, with a transfer roller 2 and a cutting roller 3 on the frame, and the transfer roller is installed under the cutting roller, which is characterized in that: it is installed on the frame on the side of the cutting roller A blowing duct 4, the blowing duct has an outlet 5, the outlet faces the corner waste 6 produced in the cutting part and faces the outer side 7, and the blowing duct is connected to the air supply device 8.

[0017] When the present invention is used, the outlet of the blowing device blows air against the cutting part of the paper 12, so that the blowing outlet will blow out the scraps that fall off, so that they will not be involved in the conveying roller or fall into the printing device. , to ensure the normal use of the printing paper cutting device, the direction of the arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com