A multifunctional strong impact simulation test device and method

A technology of simulating test and test method, applied in impact test, measuring device, testing of machine/structural components, etc., can solve the problems of many experiments, increased test cost, complicated tooling, etc., and achieve the effect of suppressing clutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

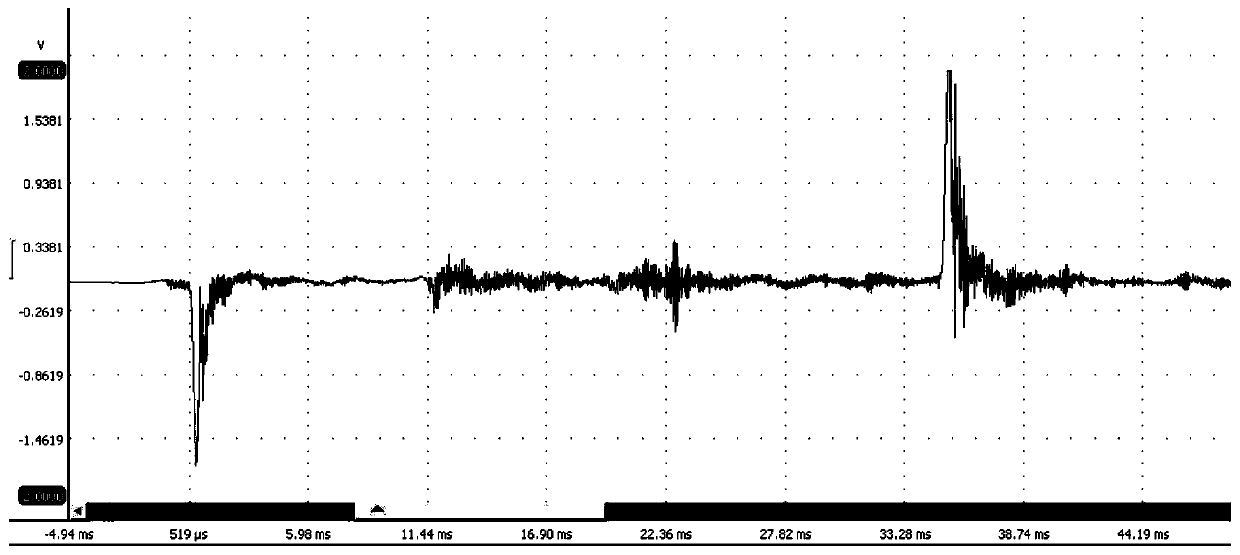

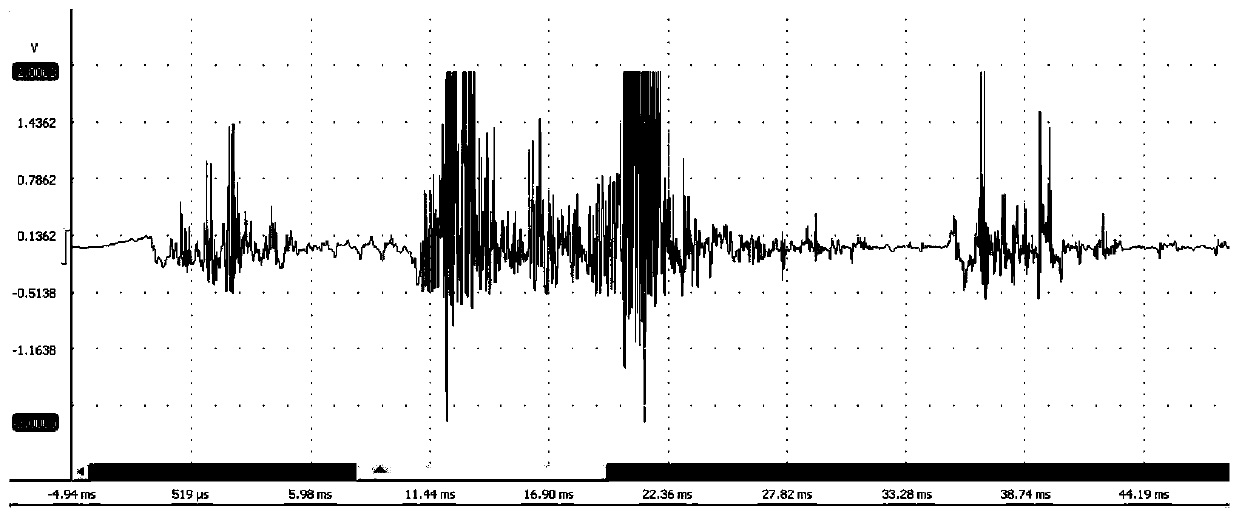

Examples

Embodiment 1

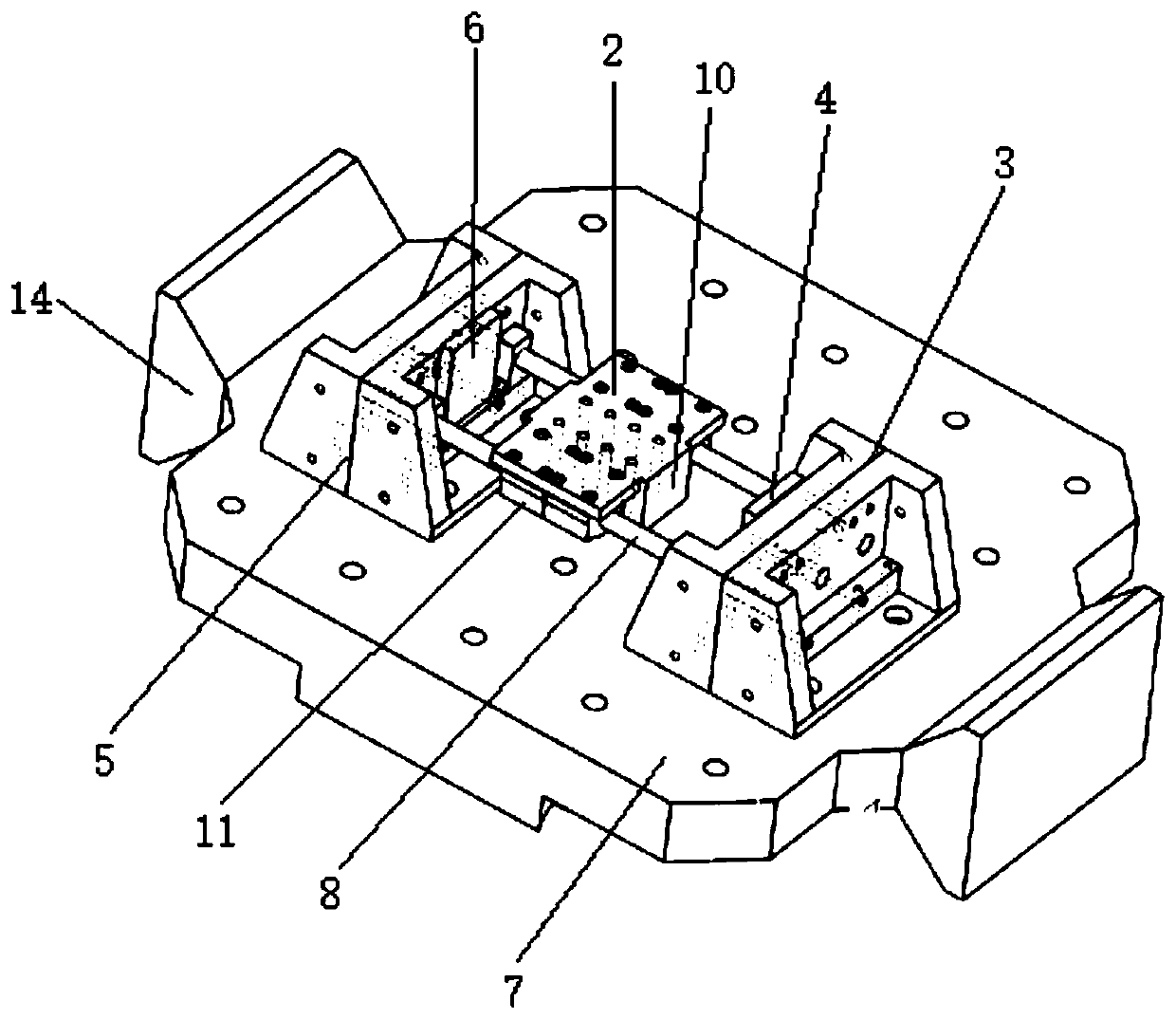

[0036] The invention provides a multifunctional strong impact simulation test device, the specific structure is as follows figure 1 and figure 2 As shown, it includes a power unit and a multifunctional strong impact device, and the multifunctional strong impact device includes a sliding work surface 2, a front baffle 3, a front baffle cushion 4, a rear baffle 5 and a rear baffle cushion 6; this implementation The power device in the example is an aerodynamic horizontal shock response spectrum impact table, and the front baffle 3 and the rear baffle 5 are installed on the shock response plate 7 of the aerodynamic horizontal shock response spectrum impact table. The aerodynamic horizontal shock response spectrum shock table in this embodiment is an existing device, and its specific structure will not be described here.

[0037]The front fender 3 and the rear fender 5 are arranged oppositely, the distance between the front fender 3 and the rear fender 5 is adjustable, and a pai...

Embodiment 2

[0054] Such as Figure 5 As shown, when the test conditions of the horizontal shock response spectrum table are not available, the power device includes a high-speed impact cylinder and a horizontal metal base 9, and an impact through hole is opened in the middle of the tailgate 5, and the high-speed impact cylinder includes an impact cylinder 12 and a cylinder piston rod 13. The impact cylinder 12, the rear baffle 5 and the front baffle 3 are successively installed on the horizontal metal base 9. There is a gap between the cylinder piston rod 13 and the rear baffle 5, and the cylinder piston rod 13 can be quickly extended under the air pressure. The impact head 10 goes out and passes through the impact through hole to collide with the impact head 10 of the sliding table 2 at a high speed.

[0055] The test method of the multifunctional strong impact simulation test device provided by the embodiment of the present invention 2 comprises the following steps:

[0056] Step 1: In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com