Construction method of two-wall sandwiched plastic film for sandy soil dike foundation seepage cutoff

A construction method and technology of cut-off walls, which are applied in infrastructure engineering, water conservancy engineering, sea area engineering, etc., can solve problems such as impracticability and technical difficulties in lapping, so as to improve construction efficiency, avoid sharp bend construction and space obstacles, The effect of increasing the seepage diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

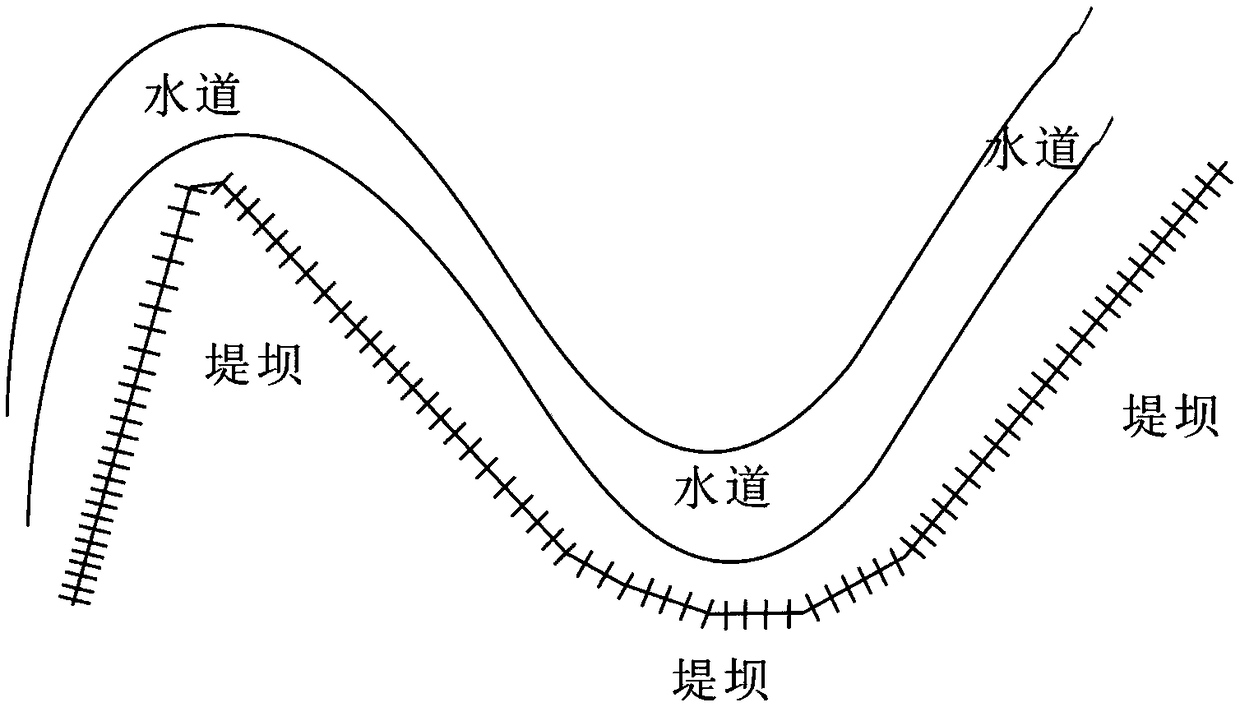

[0033] Suppose a certain section of embankment is located on the sand embankment foundation, the length of the embankment is 1120 meters, the embankment width is 15-20 meters, and the embankment height is 15 meters. This section of embankment has a first sharp bend at 430 meters, with an inflection angle of 30°, and a second sharp bend at 840 meters, with an inflection angle of 45°.

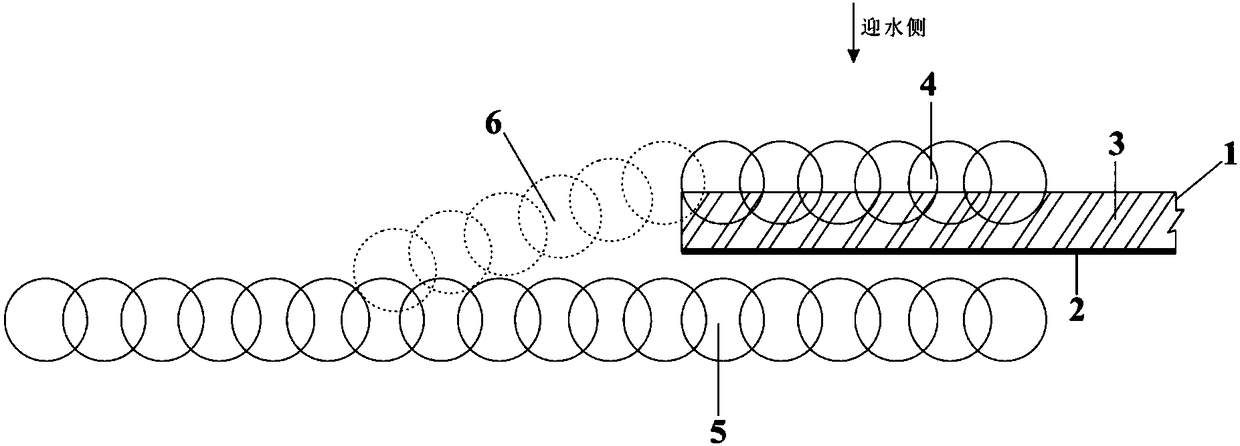

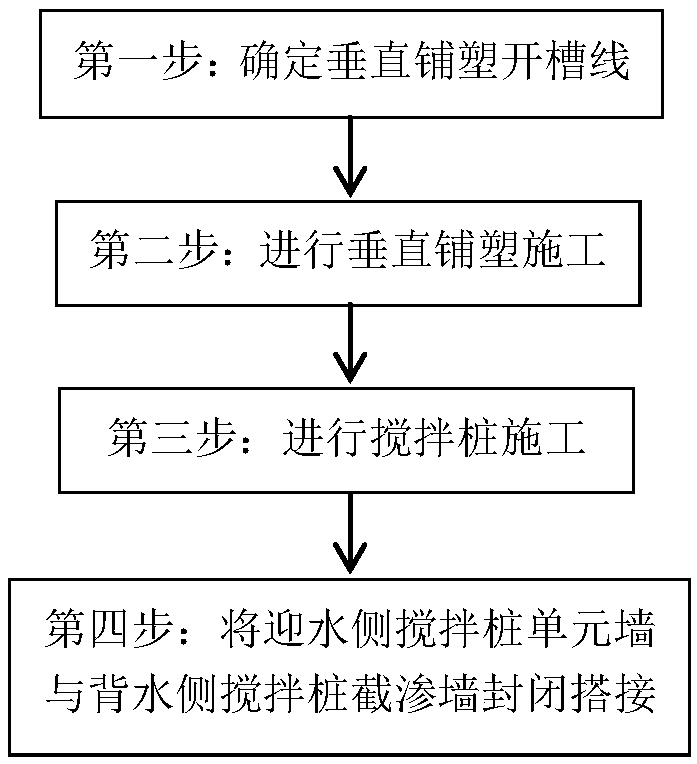

[0034]Carry out embankment seepage intercepting project according to set condition, at first adopt conventional vertical plastic-laying construction in embankment straight line section, form the anti-seepage groove (1) of the vertical plastic-laying of 2.5 meters wide, then adopt the sand embankment that the present invention proposes The two-wall plastic film sandwich construction method for base seepage interception is used to construct the first inflection point of the first sharp bend of the embankment, and the specific steps are as follows:

[0035] The first step is to determine the vertica...

Embodiment 2

[0041] Suppose a section of embankment is located on a sandy soil embankment foundation, with a dike length of 360 meters, a dike width of 15-20 meters, and a dike height of 15 meters. This section of embankment has a sharp bend section at 180 meters, and the inflection point angle of the sharp bend section is 35°.

[0042] The embankment seepage interception project of this section adopts conventional vertical plastic-laying construction in the straight section of the embankment to form a 2.5-meter-wide vertical plastic-laying anti-seepage groove (1), and then adopts the two walls proposed by the present invention for intercepting seepage of the sand embankment foundation The plastic film construction method is used to construct the first inflection point of the sharp bend section of the embankment. The specific construction steps are as follows:

[0043] The first step is to determine the vertical plastic laying slot line: accurately determine and record the slotting starti...

Embodiment 3

[0048] Assume that a section of embankment is located on a sandy soil embankment, with a length of 520 meters, a width of 15-20 meters, and a height of 15 meters. This section of embankment has a sharp bend section at 310 meters, and the inflection point angle of the sharp bend section is 27°.

[0049] The embankment seepage interception project of this section adopts conventional vertical plastic-laying construction in the straight section of the embankment to form a 2.5-meter-wide vertical plastic-laying anti-seepage groove (1), and then adopts the two walls proposed by the present invention for intercepting seepage of the sand embankment foundation The plastic film construction method is used to construct the first inflection point of the sharp bend section of the embankment. The specific construction steps are as follows:

[0050] The first step is to determine the vertical plastic laying slot line: accurately determine and record the slotting starting point of the anti-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion force | aaaaa | aaaaa |

| Expansion force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com