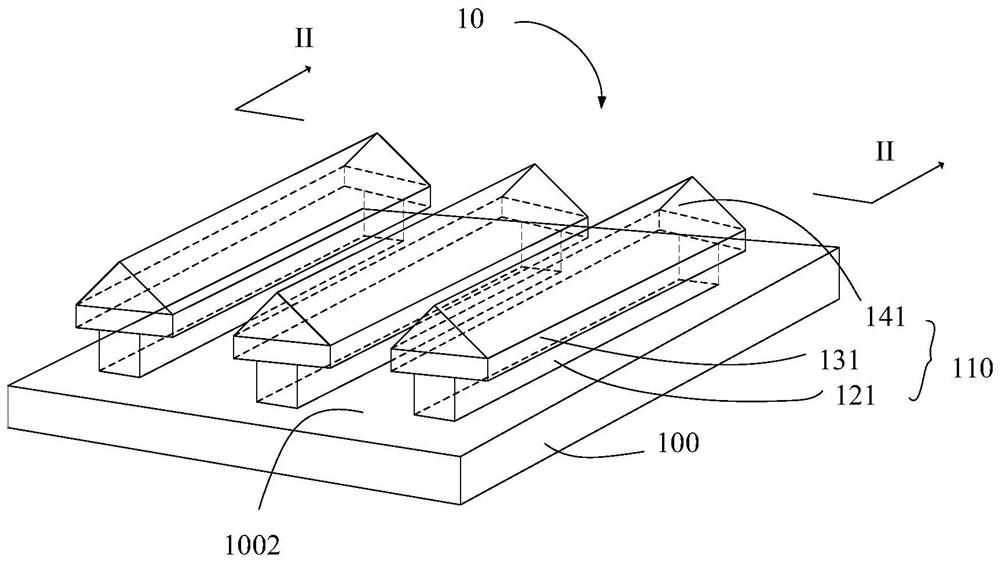

Pine-like metal nanograting

A technology of metal nano and pine trees, which is applied in the direction of diffraction grating, nanotechnology, nanotechnology, etc., can solve the problems of large structure size, difficulty of three-dimensional gold nanostructure, limiting application and development, etc., and achieves the effect of expanding the range and realizing broadband absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

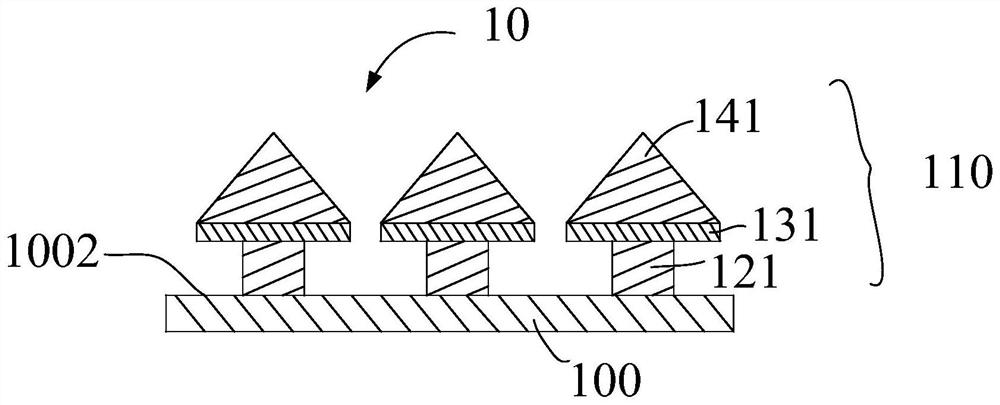

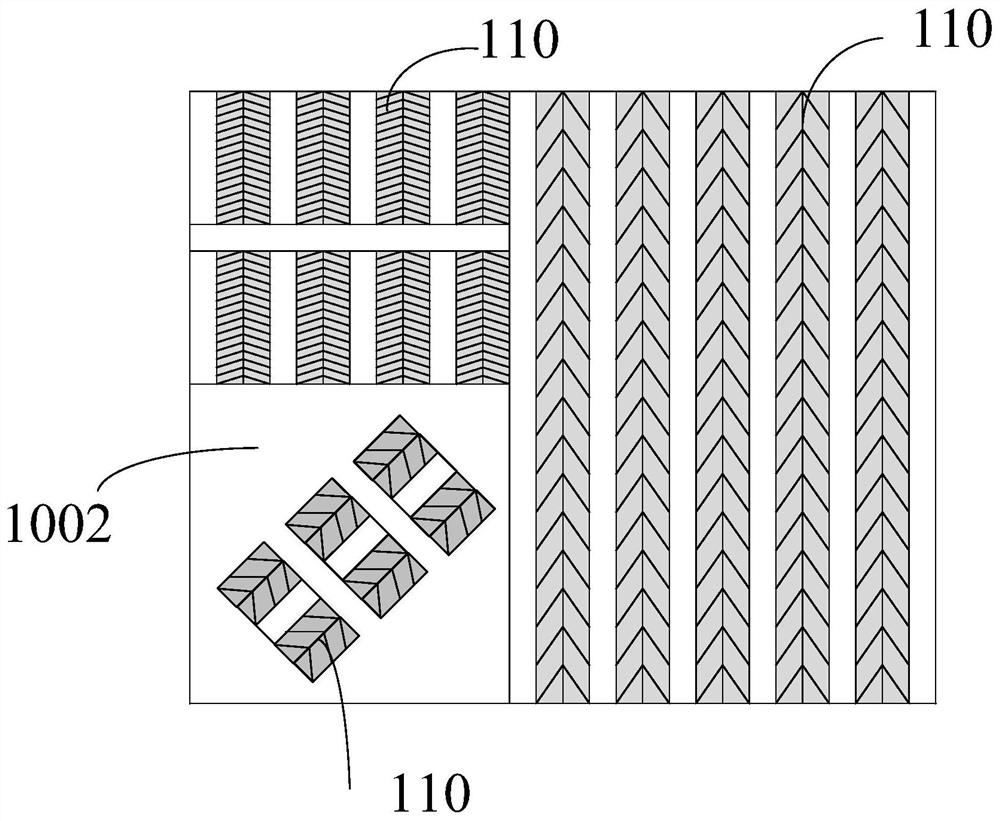

[0031] see Figure 5 , the first embodiment of the present invention provides a method for preparing the pine-like metal nano-grating 10 . The preparation method of the pine-like metal nano-grating 10 comprises the following steps:

[0032]S10: providing a substrate 100;

[0033] S20: disposing a first metal layer 120 on the surface of the substrate 100, disposing an isolation layer 130 on the surface of the first metal layer 120 away from the substrate 100, and disposing an isolation layer 130 on the surface of the isolation layer 130 away from the first metal layer 120 setting a second metal layer 140;

[0034] S30: disposing a patterned first mask layer 151 on the surface of the second metal layer 140 away from the isolation layer 130, the patterned first mask layer 151 covering a partial area of the surface of the second metal layer 140 , and expose the rest of the area;

[0035] S40: Etching the second metal layer 140 to obtain a plurality of parallel and spaced tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com