Double-glass photovoltaic module and manufacturing method thereof

A technology of double-glass photovoltaic and manufacturing method, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of low power of photovoltaic modules, and achieve the effect of overcoming the problem of water vapor transmission, expanding the spacing between sheets, and reducing production and manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

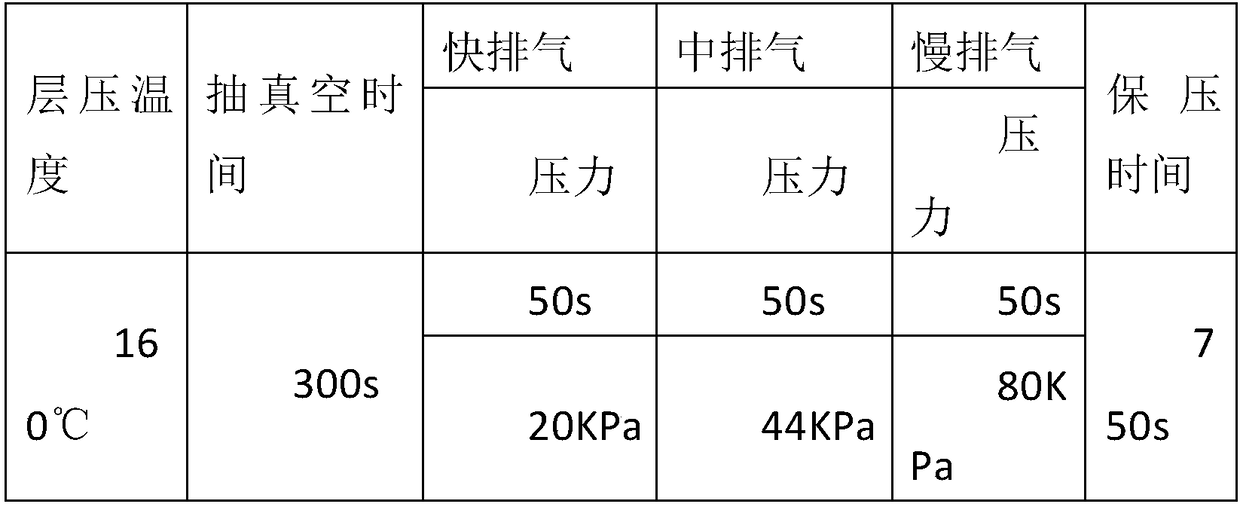

[0032] Example: A double-glass photovoltaic module and its manufacturing method

[0033] The manufacturing method of the double-glass photovoltaic module in this embodiment includes the following steps:

[0034] In the first step, an embossed coated glass is taken, and an encapsulating film is laid on the embossed coated glass.

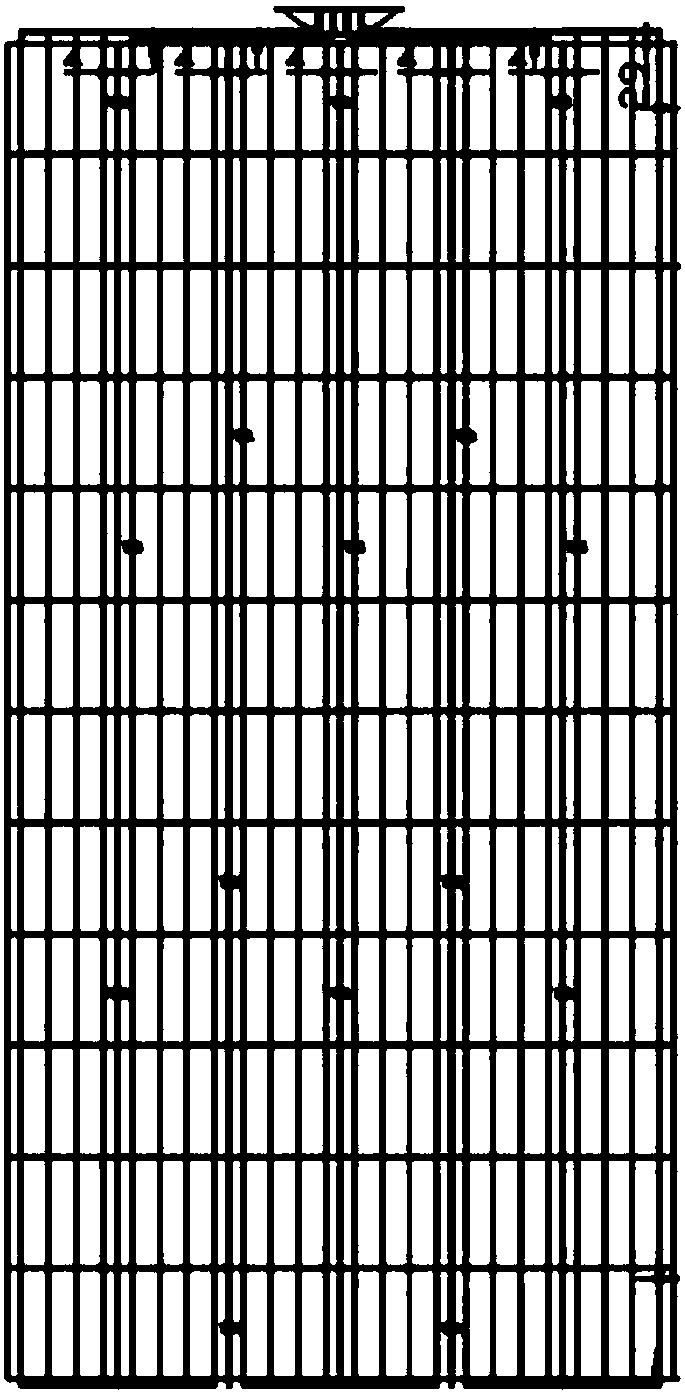

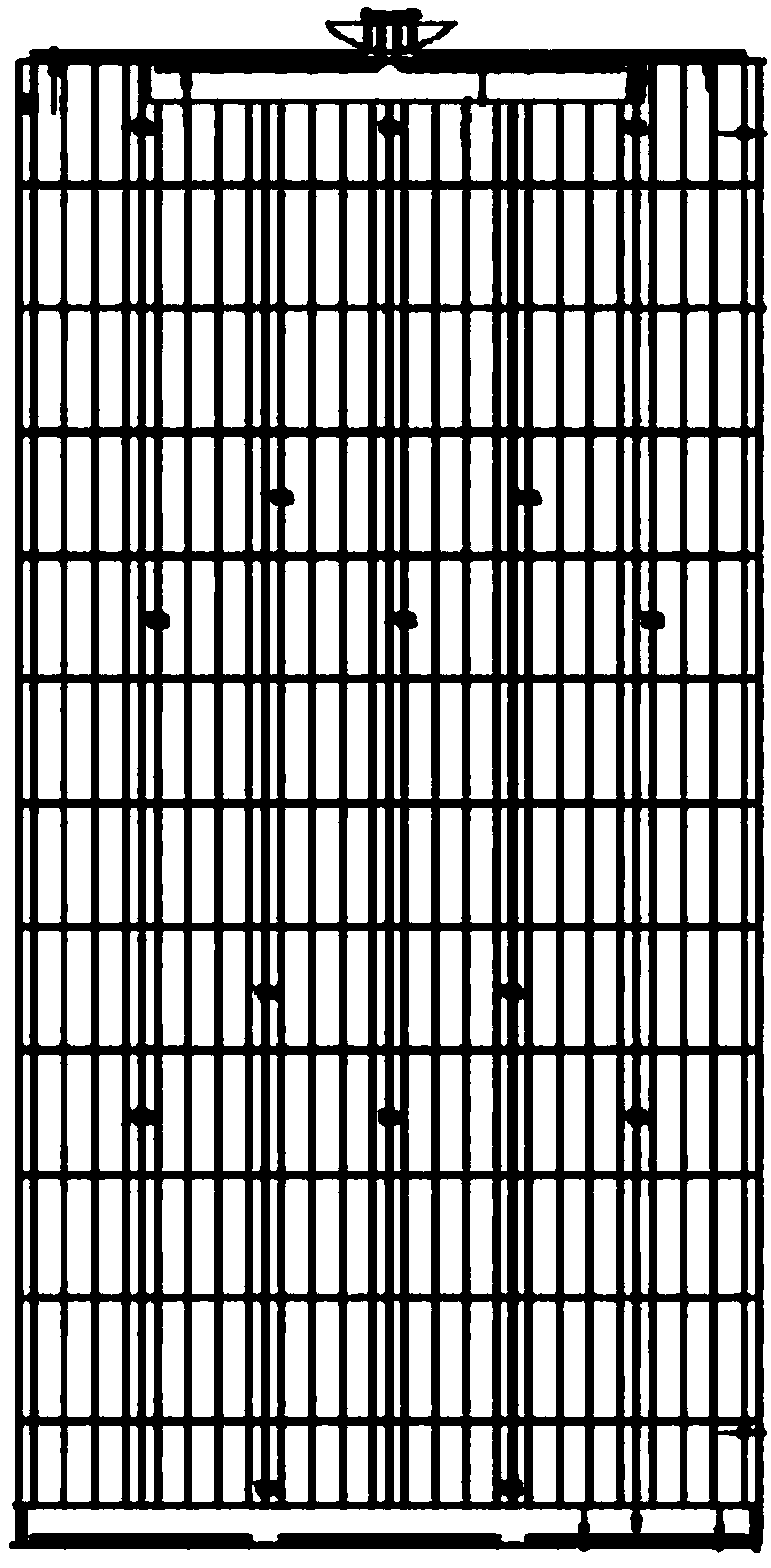

[0035] In the second step, place the 6 battery strings on the embossed coated glass after laying the encapsulation film in the order of "left positive, right negative", and fix the position of the battery strings with high temperature tape. Among them, when placing battery strings, there are 6 strings of battery strings (counting from the left are +-+-+-).

[0036] The third step, the third bus bar welding: Lay the tail adhesive film strip and the tail insulation strip in sequence at the position of the battery string tail 3-5mm away from the tail interconnection strip, and fold the tail interconnection strip to the battery sheet for welding. The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com