A kind of preparation method and product of ultra-thin double-glass photovoltaic module

A dual-glass photovoltaic and module technology, applied in photovoltaic modules, photovoltaic power generation, electrical components, etc., can solve the problems of easy occurrence of bubbles, expansion of parallel series, delamination, etc., to achieve short lamination time, improve production efficiency, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Example: Preparation of the ultra-thin double-glass photovoltaic module of the present invention.

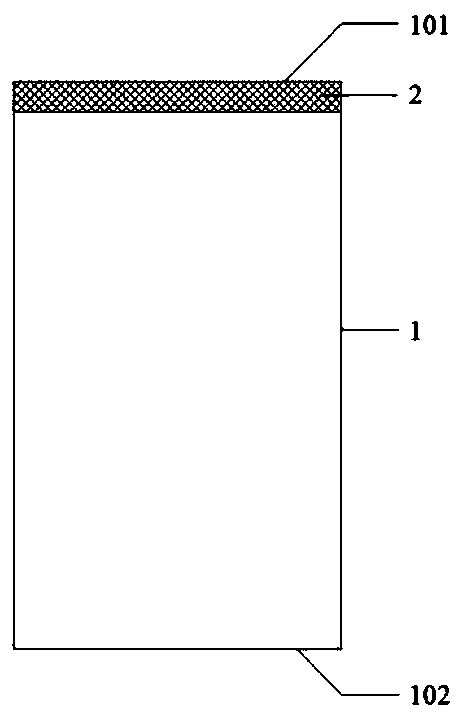

[0041](1) First, select a rectangular ultra-clear embossed tempered glass with a thickness of 2mm, a width of 990mm, and a length of 1660mm as the upper glass 1, and set the two short sides on the surface defined by the length and width of the upper glass 1 as Head 101 and afterbody 102, then a thickness is 0.6mm on the head 101 pad, and width is 50mm, and length is the head strip adhesive film 2 (POE adhesive film) of 990mm (as figure 1 shown), and then lay an upper layer of packaging film 3 (POE film) with a thickness of 0.6mm, and the upper layer of packaging film 3 covers the head strip film 2.

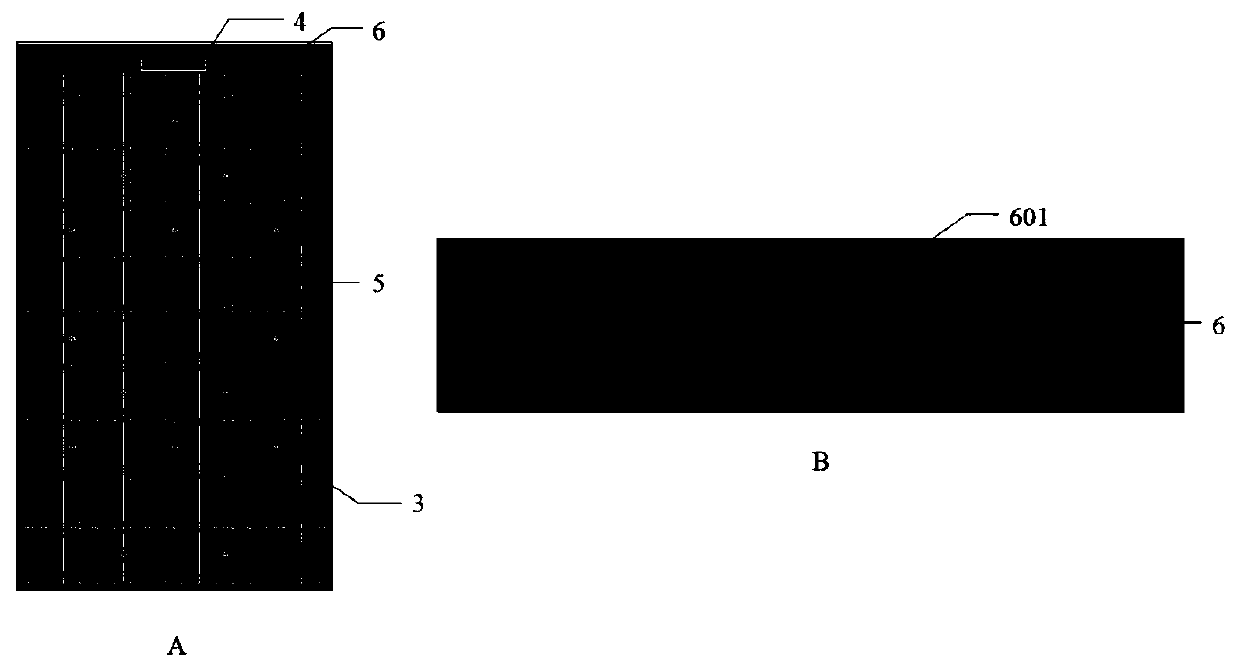

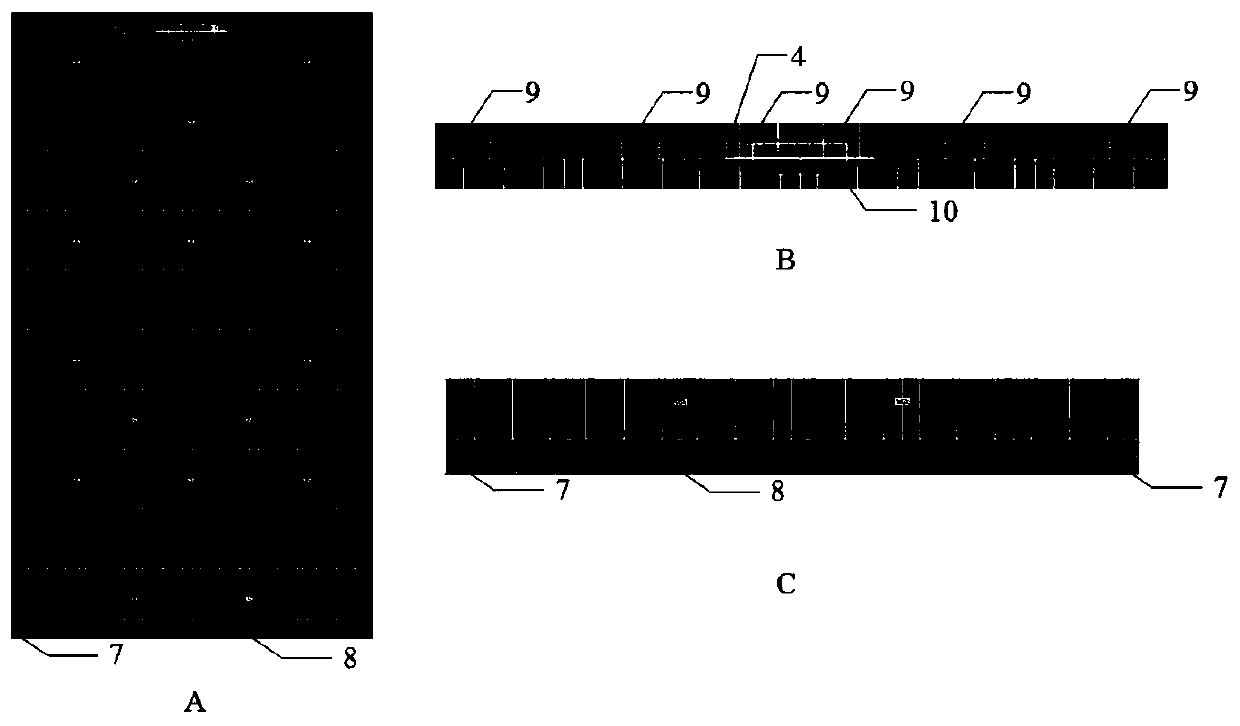

[0042] (2) First place an insulating backplane 4 (TPT backplane) with a thickness of 0.34mm, a width of 50mm, and a length of 150mm at the position corresponding to the center of the head 101 of the upper glass 1. The insulating backplane 4 is located at the Above the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com