An aircraft horizontal wing test bracket

A horizontal and wing technology, applied in the field of aircraft wing installation and debugging equipment, can solve the problems of heavy weight of the wing, inability to accurately guarantee the angle required for installation, and large manpower input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is realized through the following technical solutions:

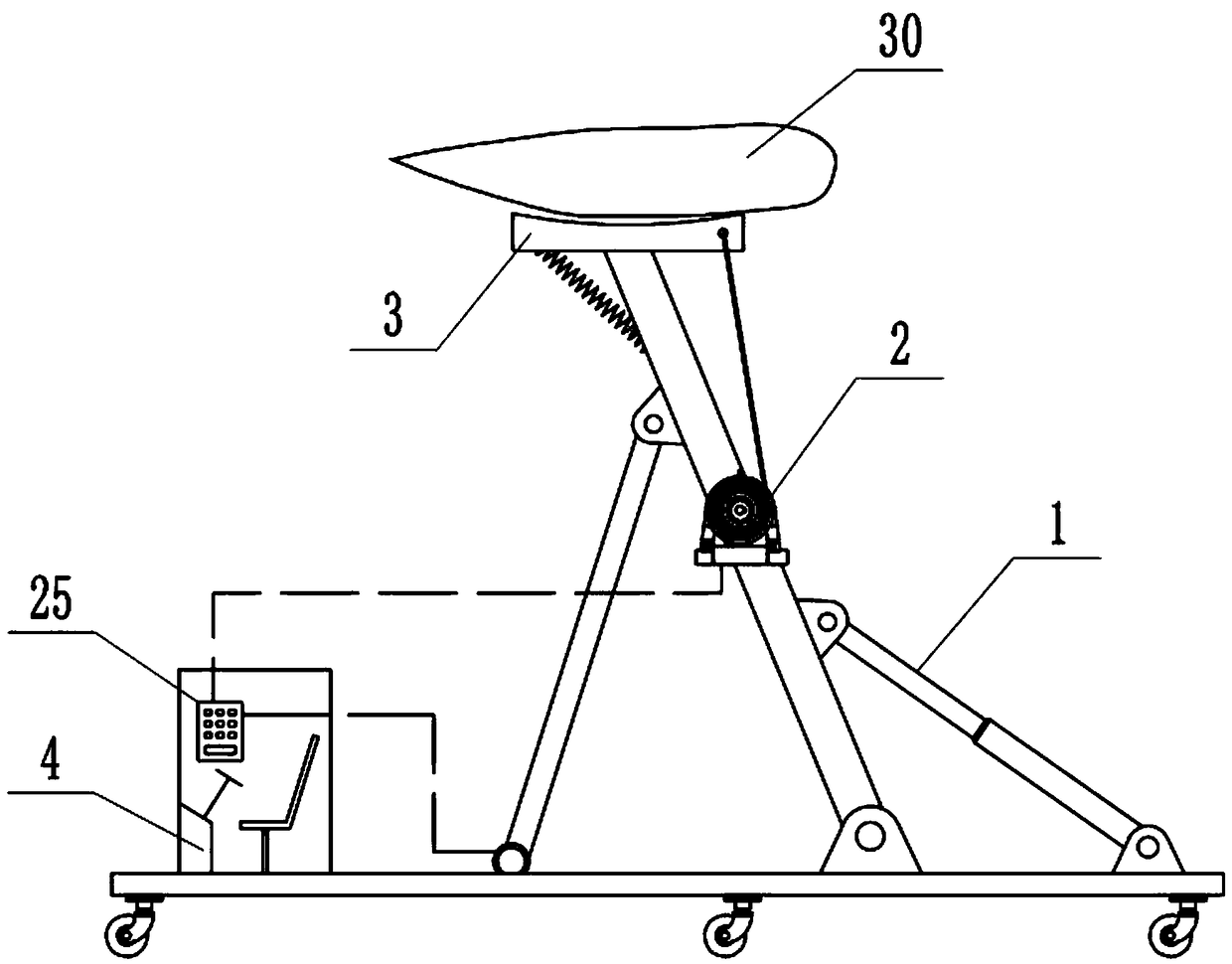

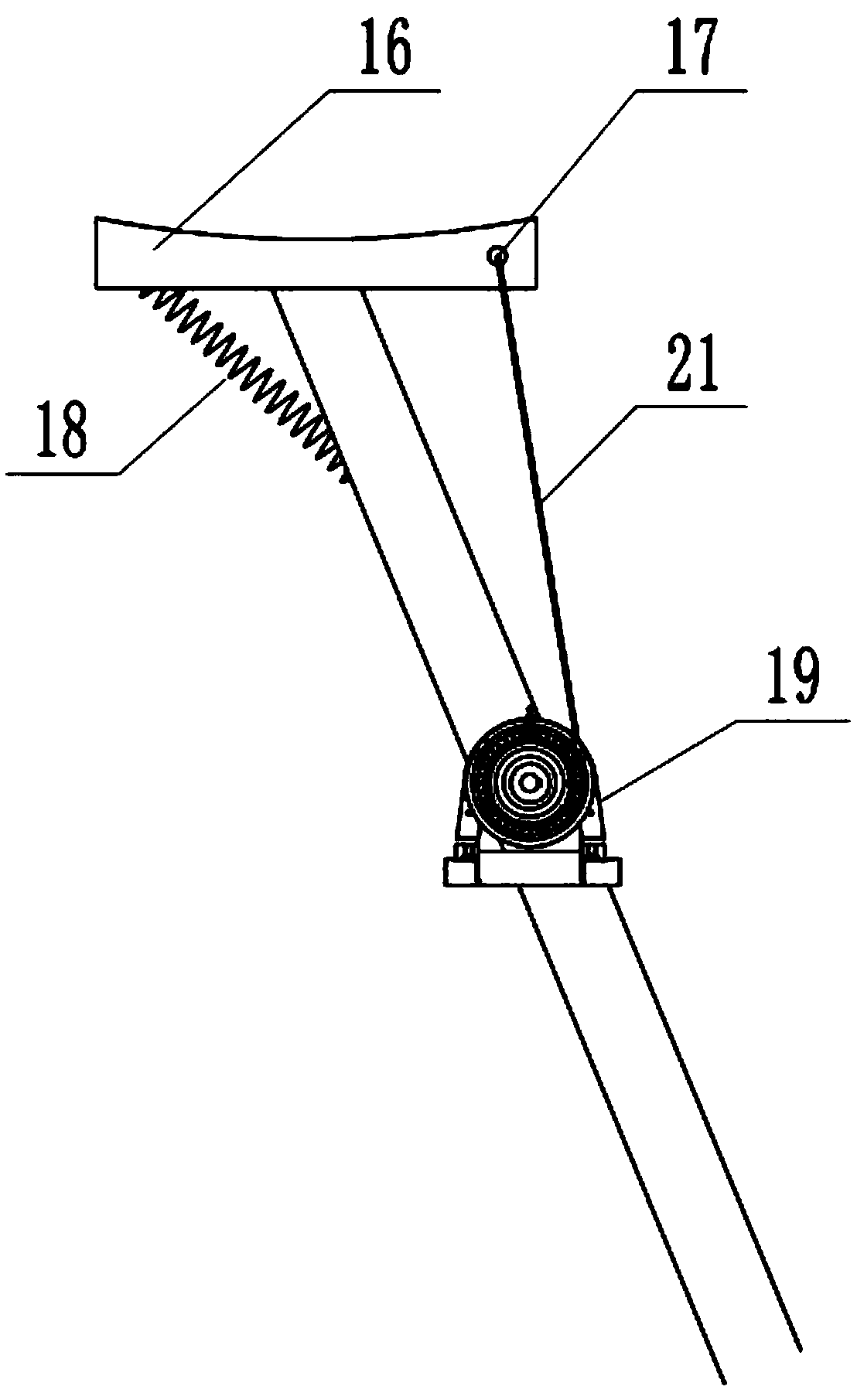

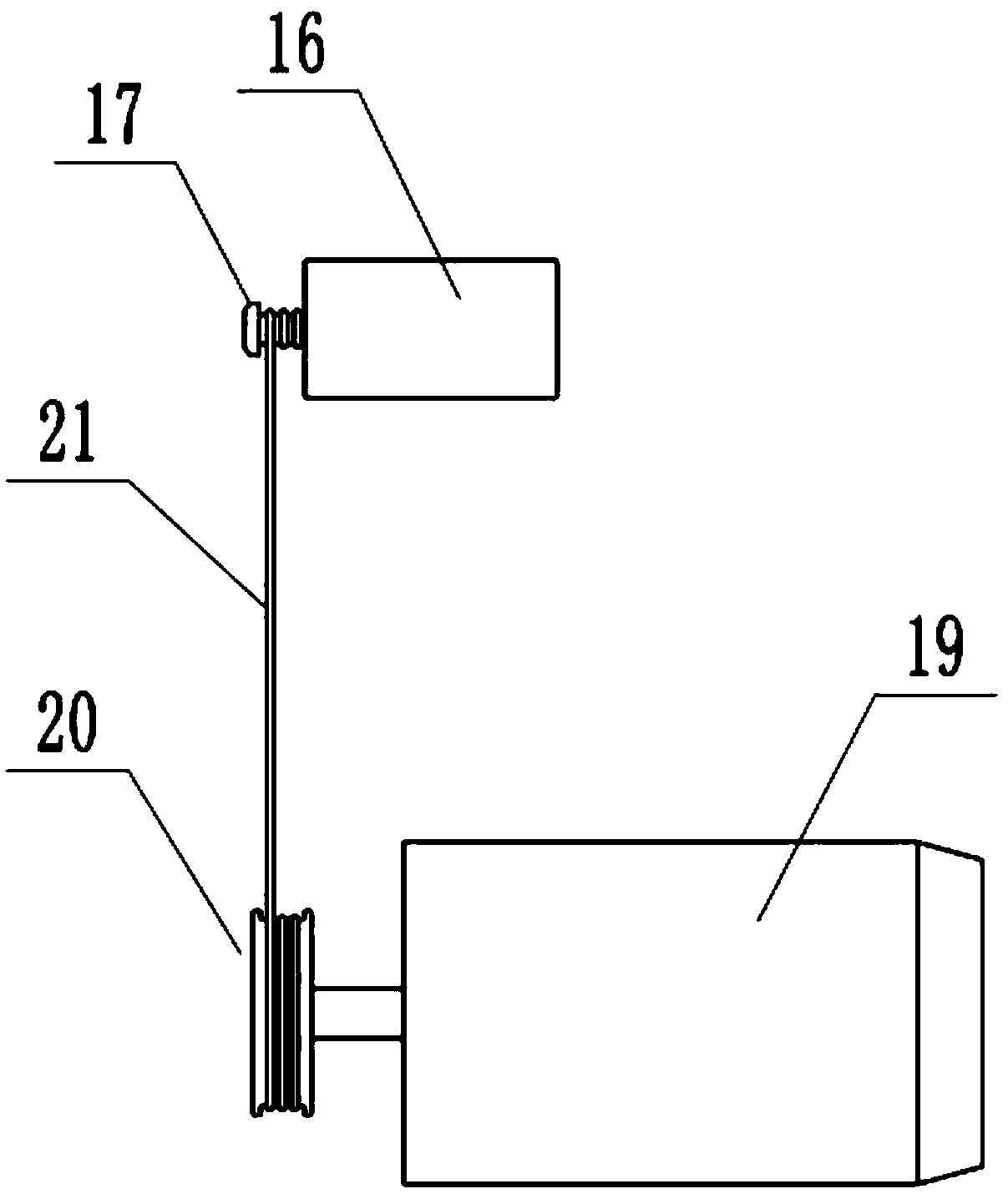

[0023] An aircraft horizontal wing test bracket, comprising a lifting mechanism 1, a driving mechanism 2, a bracket mechanism 3 and a moving mechanism 4, the lifting mechanism 1 is located above the moving mechanism 4, and the bracket mechanism 3 is located at the lifting mechanism 1 above, the driving mechanism 2 is arranged on the lifting mechanism 1, and is used to drive the bracket mechanism 3. It is characterized in that: the lifting mechanism 1 includes a supporting plate 5, a main supporting seat 6, a main supporting rod 7, and a secondary connecting seat 8. Auxiliary support rod 9, lifting support seat 10, lifting connection seat 11, lifting rod 12, travel motor 13, gear 14 and rack 15, the main support rod 7 and the support plate 5 are movably connected through the main support seat 6, The lifting rod 12 is movably connected with the supporting plate 5 through the price-raising suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com