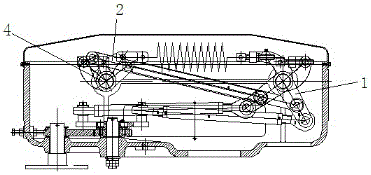

High voltage isolating switch arm assembly tooling

A high-voltage isolating switch and assembly tooling technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of no tooling, difficulty, and low efficiency, and achieve the effects of easy operation, improved assembly efficiency, and guaranteed installation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

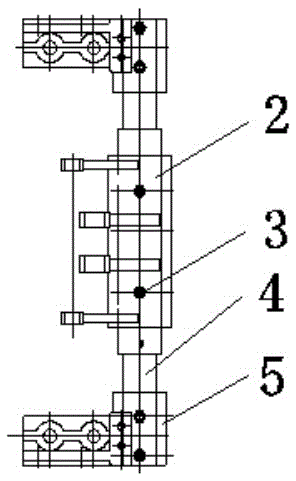

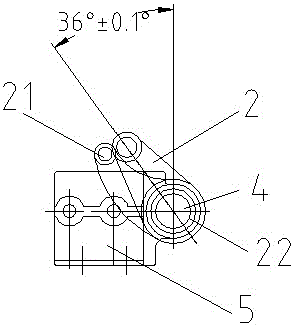

[0024] Embodiment 1 of the present invention is as Figure 5-9 As shown: it includes a base 15, two bracket positioning plates 7 arranged on the base 15 along the left and right directions, two positioning blocks 8 located between the two bracket positioning plates 7 along the left and right directions on the base 15, The crank arm positioning plate 9 arranged between the two positioning blocks 8, the two pressure plate support screws 11 arranged on the base 15 on the front and rear sides of the crank arm positioning plate 9, and the two support positioning plates 7 outside are arranged along the left and right direction. Positioning plates 16 at both ends on the base 15 and four suspension rings 13 arranged in the upper direction of the base.

[0025] The support positioning plate 7 has the upper supporting surface and the surrounding sides for press-fitting the inner side of the conductive tube support downward, and the outer surface of the support positioning plate away fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com