A dynamic design method for high-speed electric spindle rotor-bearing-housing system

A high-speed motorized spindle and system dynamics technology, applied in design optimization/simulation, computer-aided design, calculation, etc., can solve problems such as misleading motorized spindle dynamic design, large error in the calculation result of the critical speed of the motorized spindle rotor, and time-consuming solution. Achieve the effect of shortening the R&D cycle, improving the dynamic design accuracy, and reducing the design risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] A method for dynamic design of a high-speed electric spindle rotor-bearing-housing system of the present invention will be further described in detail in conjunction with an embodiment (MK2860 / 1-91 electric spindle for internal grinding machine).

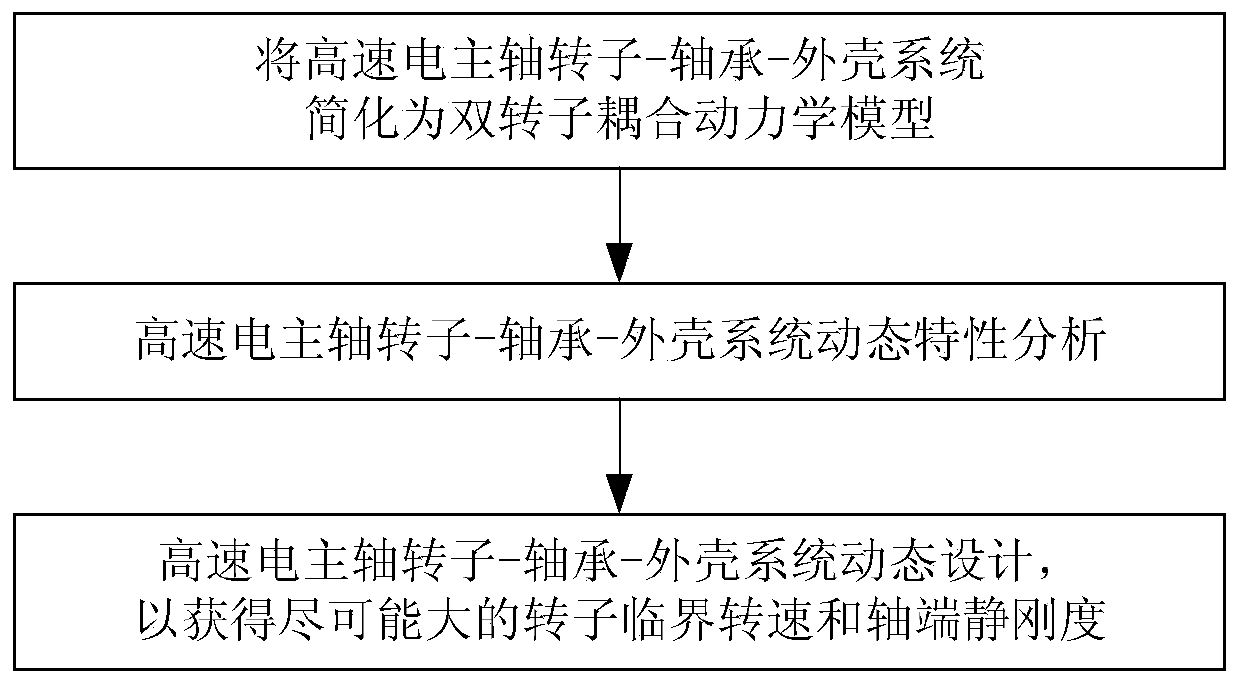

[0070] figure 1 The specific content of a dynamic design method for a high-speed electric spindle rotor-bearing-housing system of the present invention is given, including the following steps:

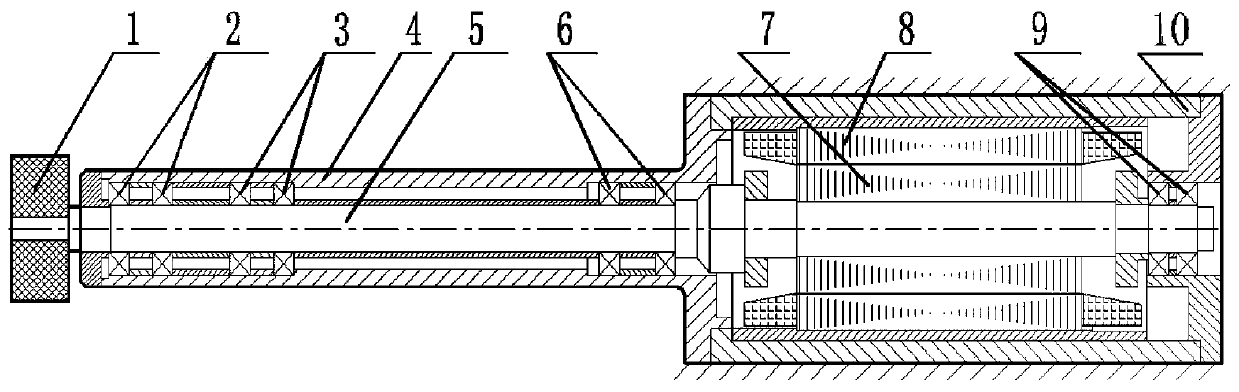

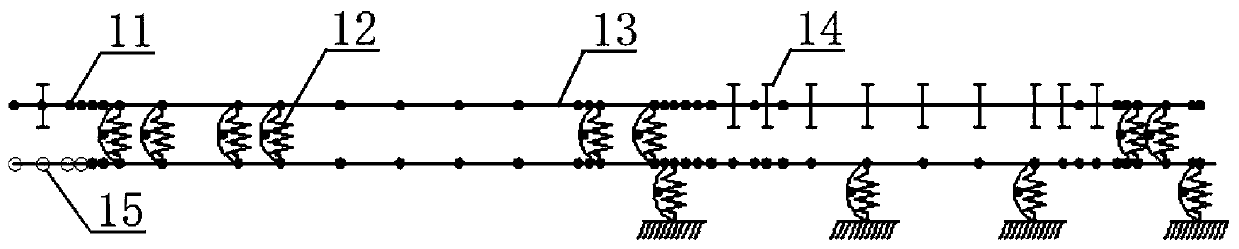

[0071] Step 1: If figure 2 The structure of the high-speed electric spindle shown is: the main shaft rotor 5 adopts four pairs of rolling bearings 2, 3, 6 and 9 to be installed in the casing 4 and the shaft sleeve 10, wherein the first three pairs of rolling bearings 2, 3 and 6 are located in the casing 4 Inside, the fourth pair of rolling bearings 9 is located in the shaft sleeve 10, the housing 4 is fixed on the front end of the shaft sleeve 10 in the form of a cantilever single support, the grinding wheel 1 is installed at the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com