Kiln car transferring equipment with positioning and parking functions

A kiln car and equipment technology, applied to lighting and heating equipment, furnaces, furnace components, etc., can solve the problems of low work efficiency, labor and time-consuming, and the inability to realize one-time precise parking, etc., and achieve the effect of improving the efficiency of lane change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

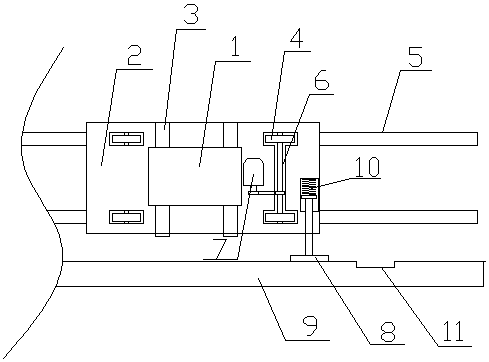

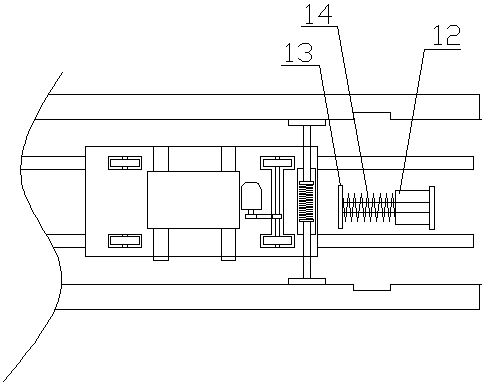

[0014] Such as figure 1 The first embodiment shown is a kiln car operating equipment with positioning parking, including a mother car 2 carrying a kiln car 1. The kiln car 1 is located on the mother car 2. The kiln car 1 is a sub-car, and the mother car 2 is loaded with a kiln car. The car guide rail 3, the kiln car 1 is located on the kiln car guide rail 3, the two sides of the bottom of the mother car 2 are provided with wheels 4, the wheels 4 are matched with the mother car guide rail 5, and the wheels 4 are fixed on the wheel shaft 6, and the wheel shaft 6 is driven by the driving device 7, and the driving device 7 is fixed on the mother car 2, and it is characterized in that: a positioning rod 8 is installed on one side of the mother car 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com