Injection molding system and method

An injection molding system and injection molding product technology, applied in coating and other directions, can solve problems such as low production efficiency, crushed injection molds, and improper placement, so as to reduce the risk of crushing molds, avoid improper placement, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

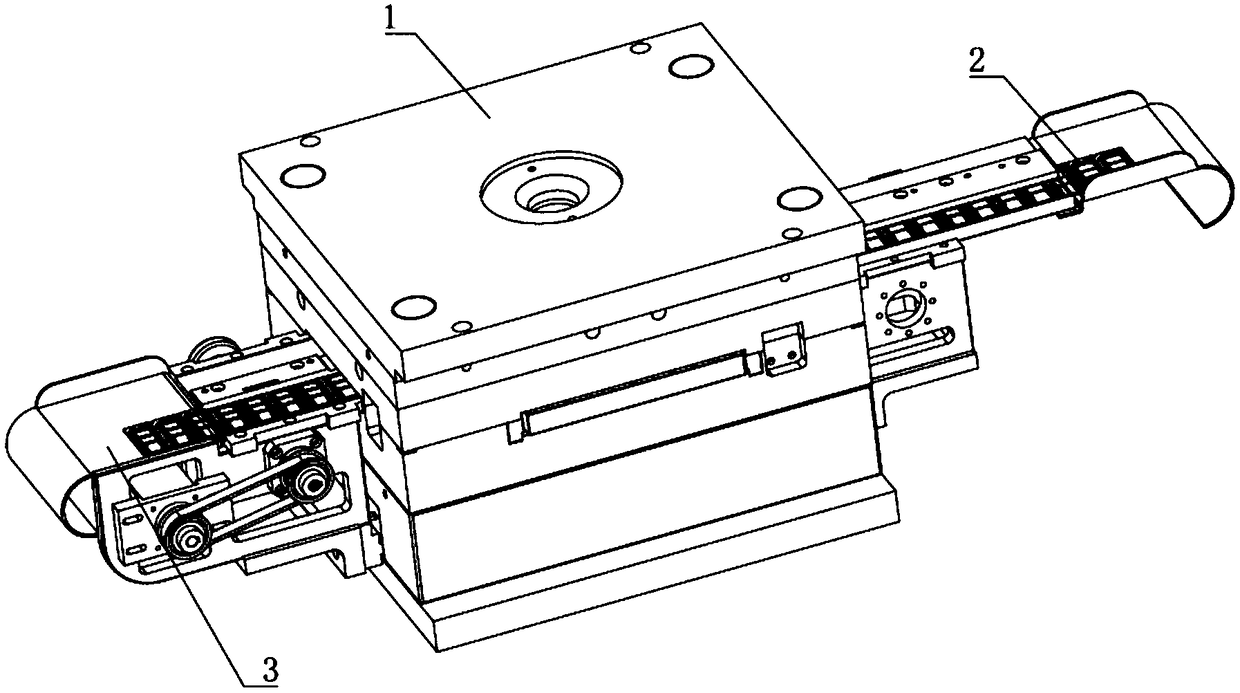

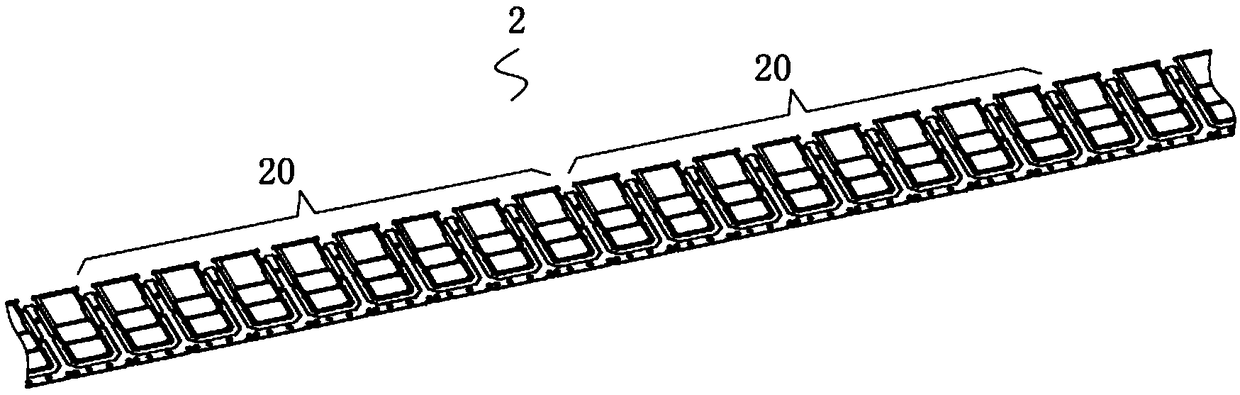

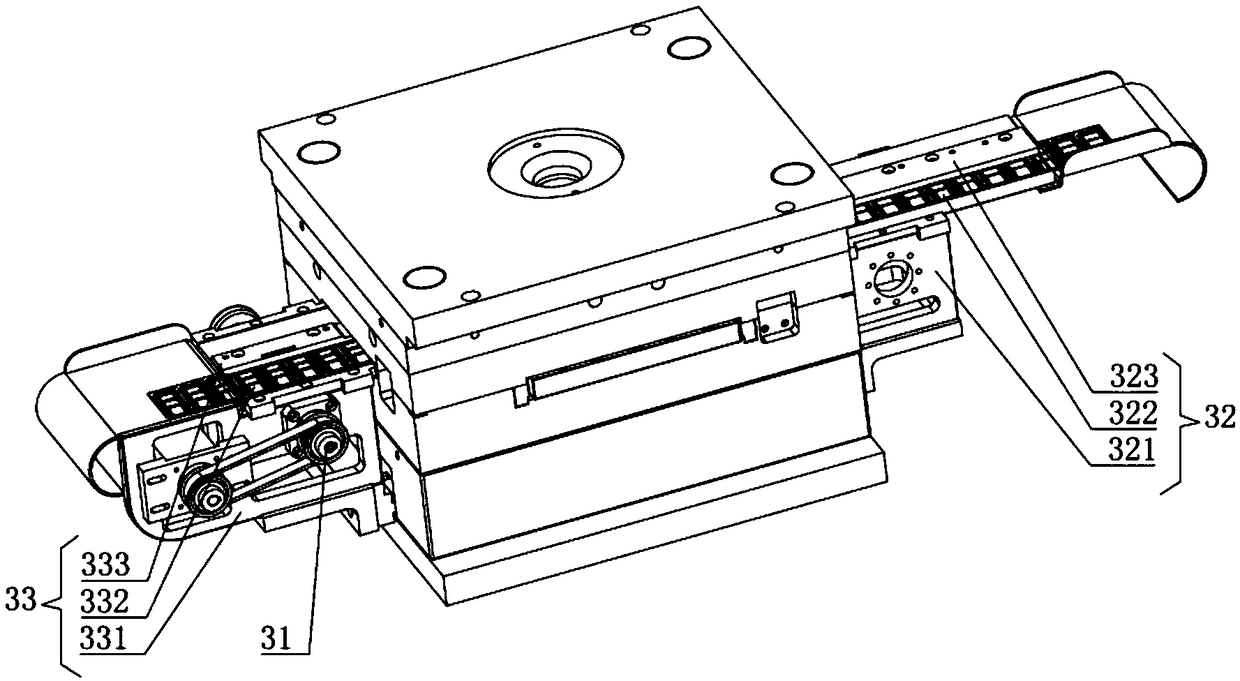

[0035] Such as figure 1 As shown, it represents an injection molding system provided by the present invention. The injection molding system includes an injection mold 1, which is used to provide a molding cavity for injection-molded products; a strip-shaped blank 2, which is used to fix the injection-molded product and / or carry injection molding raw materials; a pulling device 3, which is used to pull the strip-shaped blank 2 Move along the direction of entering and exiting the injection mold; wherein, the injection molded product is fixed on the strip blank 2 through injection molding together with the strip blank 2; when the injection mold 1 completes the molding operation of the injection molded product and opens , the pulling and feeding device 3 pulls the injection molded product out of the injection mold 1 by pulling the strip-shaped blank 2 .

[0036] Like this, when using the injection molding system provided by this embodiment to carry out injection molding operation...

Embodiment 2

[0044] The injection molding system provided by this embodiment is the same as the above embodiment in principle and similar in structure, the only difference is that, as Figure 8-9 As shown, the injection molding system provided in this embodiment also includes a feeding device 4, and a feeding trough 10 corresponding to the feeding device 4 is provided on the side of the injection mold 1 that is different from the pulling feeding device 3; The feeding device 4 is used for providing injection molding parts corresponding to the injection molding products, and feeding the injection molding parts into the injection mold 1 through cooperation with the feeding tank 10 . In this way, when using the injection molding system provided by this embodiment to carry out injection molding operations, in addition to the removal of the injection molding product and the feeding of the injection molding raw material parts through the strip blank 2, it is also possible to place additional Inje...

Embodiment 3

[0047] Such as Figure 10 As shown, it shows a kind of injection molding method provided by this embodiment, comprising the following steps:

[0048] Provide a strip-shaped blank 2 for fixing injection molding products and / or carrying injection molding raw materials; send the strip-shaped blank 2 into the injection mold 1 by pulling and feeding device 3 for injection molding to realize fixing with the injection molding product; when the injection molding After the mold 1 completes the molding operation of the injection molded product and opens the mold, the strip-shaped blank 2 is pulled by the pulling and feeding device 3 to pull the injection molded product out of the injection mold 1 .

[0049]Specifically, in this embodiment, the strip-shaped blank 2 can be gradually fed into the injection mold 1 through the pulling and feeding device 3 described in the previous embodiment. When the injection molding operation is completed, the strip-shaped blank in the injection mold 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com