Device for implementing thermodynamic cycle through intermediate cooling

A thermal cycle and cold source technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increasing the workload of staff, cumbersome operation steps, and poor control flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

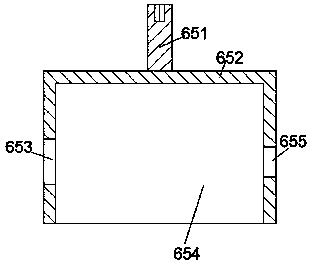

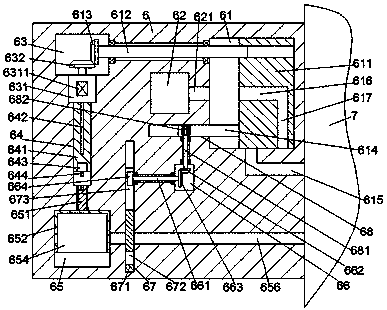

[0010] Combine below Figure 1-2 The present invention will be described in detail.

[0011] refer to Figure 1-2 According to an embodiment of the present invention, a device for realizing thermal cycle through intermediate cooling includes a thermal cycle mechanism 7 and a control body 6 fixed on the left end surface of the thermal cycle mechanism 7, and the control body 6 is equipped with There is a cold source chamber 62, the control body 6 on the right side of the cold source chamber 62 is provided with a first cavity 61, and a first slider 611 is slidably connected to the first cavity 61, and the first slider 611 is connected to the first cavity. A cavity 61 communicates with the cooling source cavity 62 and is provided with a first communication hole 621, and a first communication hole 621 is provided in the bottom end wall of the first cavity 61 to communicate with the thermal cycle mechanism 7. Two communication holes 615, the first sliding chamber 68 extending to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com