Sub-transmission direct-drive four-hammerhead precision forging machine

A four-hammer, precision forging machine technology, applied in the field of forging machinery, achieves the effect of simple and reliable structure, simple and convenient installation and maintenance, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

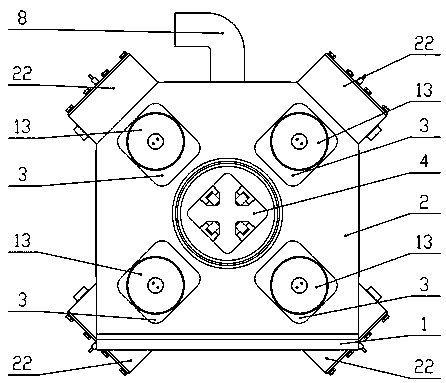

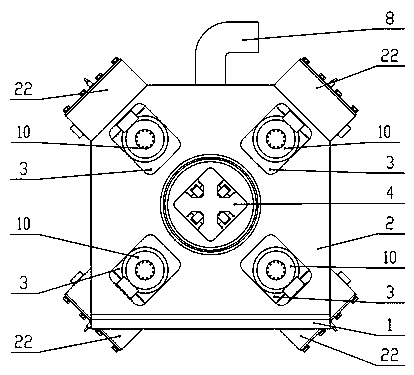

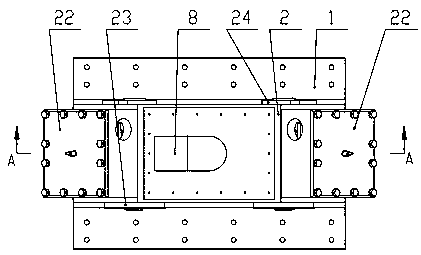

[0036] Such as Figure 1 ~ Figure 4 As shown, the technical solution adopted by the present invention includes a base 1, on which a frame 2 is installed. The frame 2 is an integral frame. On the frame 2, there are 4 cross-shaped hammer mechanism installations. Cavity 3 and a rectangular forging working cavity 4 located in the center. The frame 2 is also provided with a vertical downward dust removal hole 5, an observation hole 6 on the left and right sides, and a vertical upward smoke exhaust hole 7. Cameras can be installed in the observation holes 6 on the left and right sides to observe the forging process. The smoke exhaust holes 7 are connected to the smoke exhaust duct 8 installed at the upper end of the frame 2 to exhaust the smoke generated during the forging process. To ensure the working environment for forging, the dust removal hole 5 can timely remove the oxide scale generated during the forging process in the forging working cavity; a hammer mechanism is installed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap