Hammer rod mechanism of sub-transmission direct-drive four-hammerhead precision forging machine

A four-hammer, precision forging machine technology, applied to hammers, hammer driving devices, forging/pressing/hammer devices, etc., can solve the problems of difficult manufacturing, many processing elements, inconvenient maintenance, etc. Simple and convenient, simple and reliable transmission system, avoid the effect of transmission connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

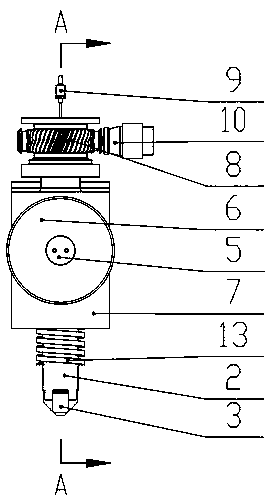

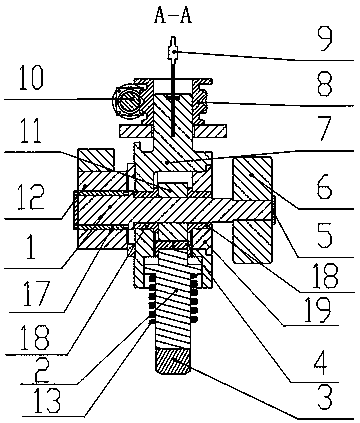

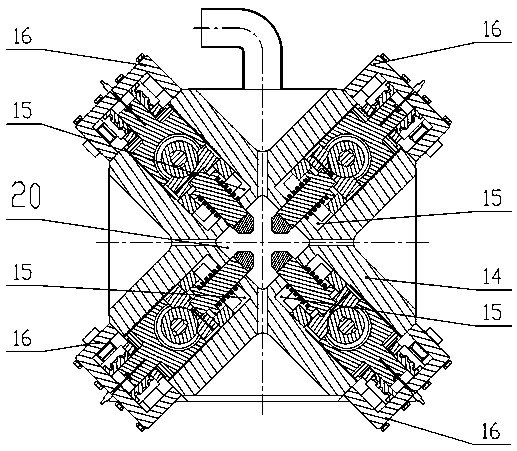

[0028] like figure 1 and figure 2 As shown, the technical solution adopted by the present invention includes a main shaft 1, a hammer shaft 2 and a hammer head 3. The main shaft 1 is a four-stage stepped shaft, and from left to right are respectively the first cylindrical section, the second cylindrical section, and the third cylindrical section. The cylinder section and the fourth cylinder section are also provided with an expansion sleeve positioning shoulder between the first cylinder section and the second cylinder section, and an expansion sleeve 17 is installed on the first cylinder section of the main shaft 1, and the expansion sleeve 17 makes the The main shaft 1 is directly connected with the motor 12. The motor 12 is a hollow servo motor. An eccentric wheel 11 is installed on the second cylindrical section of the main shaft 1. A shaft sleeve 18 is installed on the left and right sides of the eccentric wheel 11. On the left side of the shaft sleeve 18 Sliding suppor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap