A transfer vehicle convenient for loading and unloading goods in intelligent manufacturing industry

A technology of manufacturing and transfer vehicles, applied in the field of intelligent manufacturing, can solve problems that affect work progress and consume too much time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

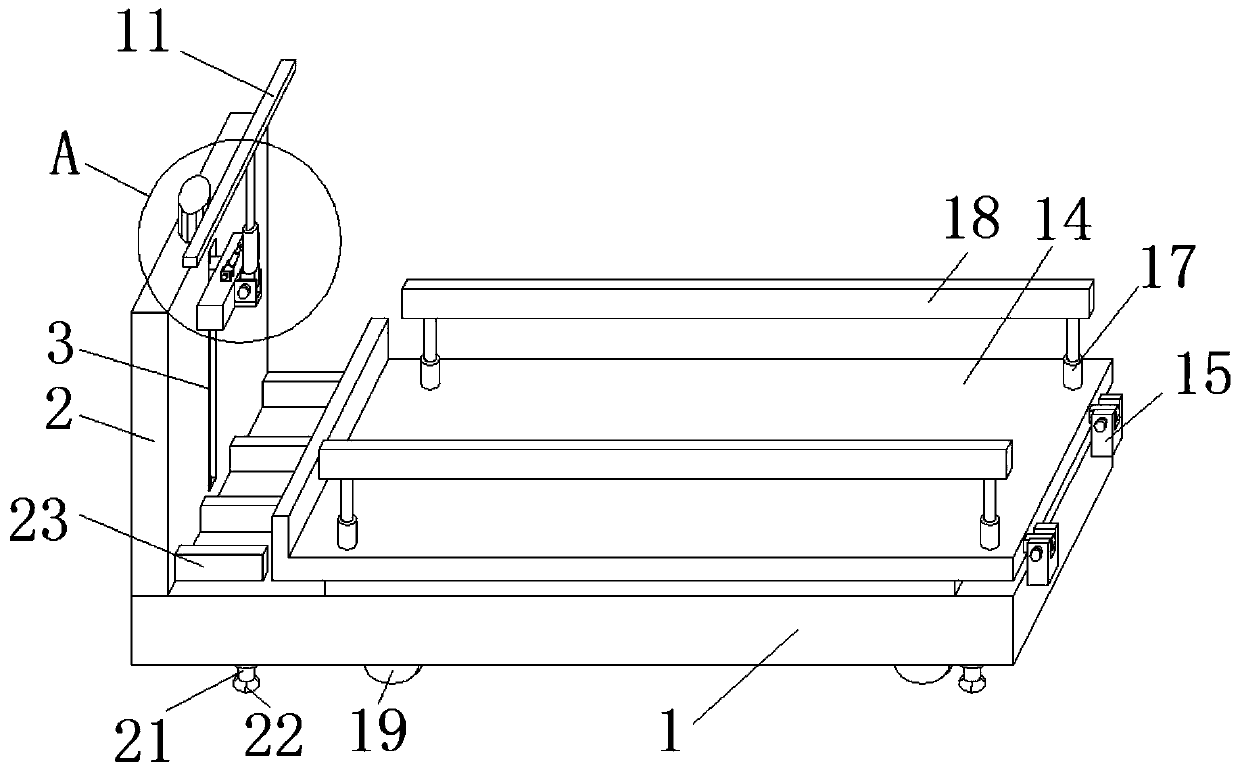

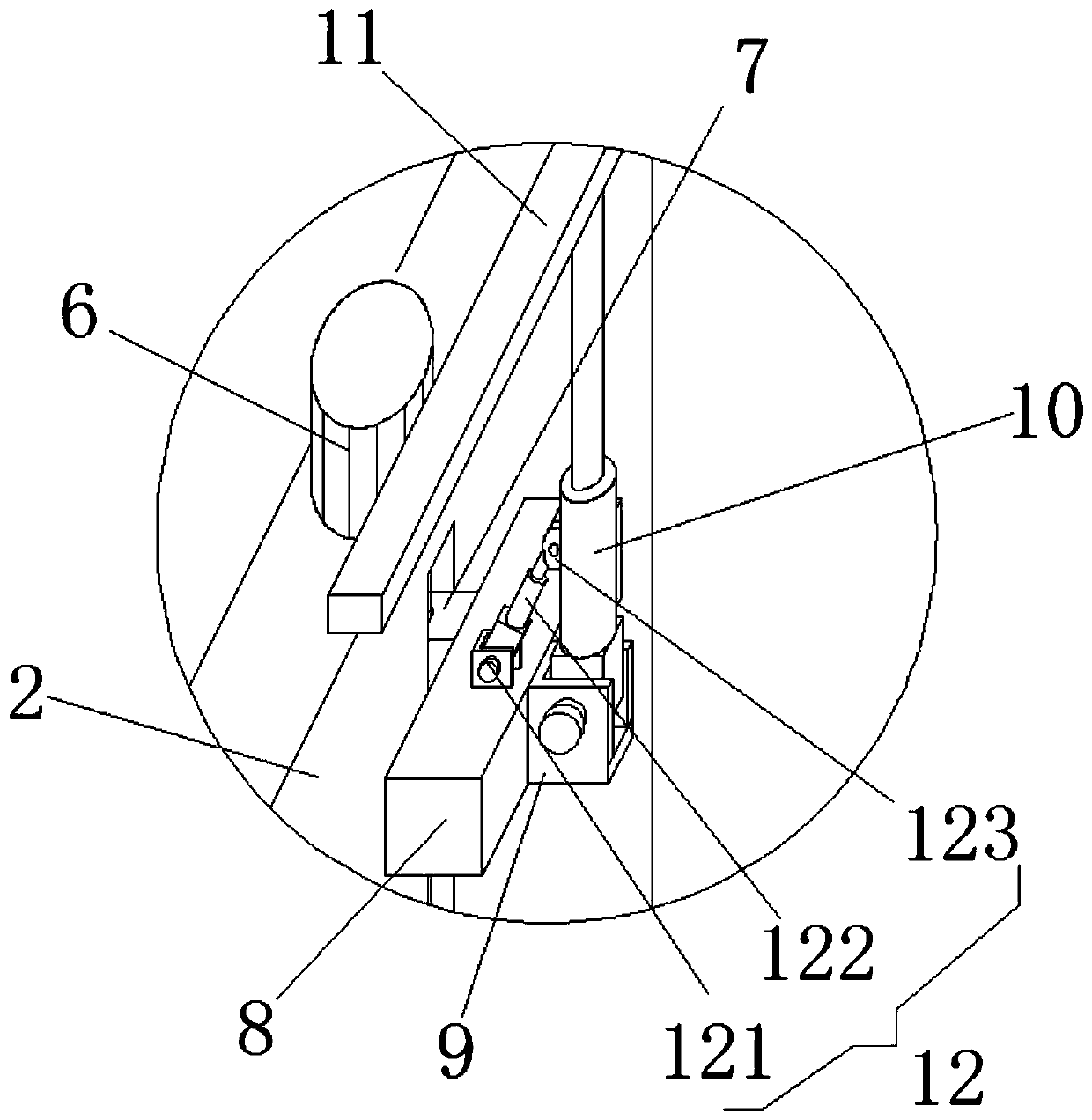

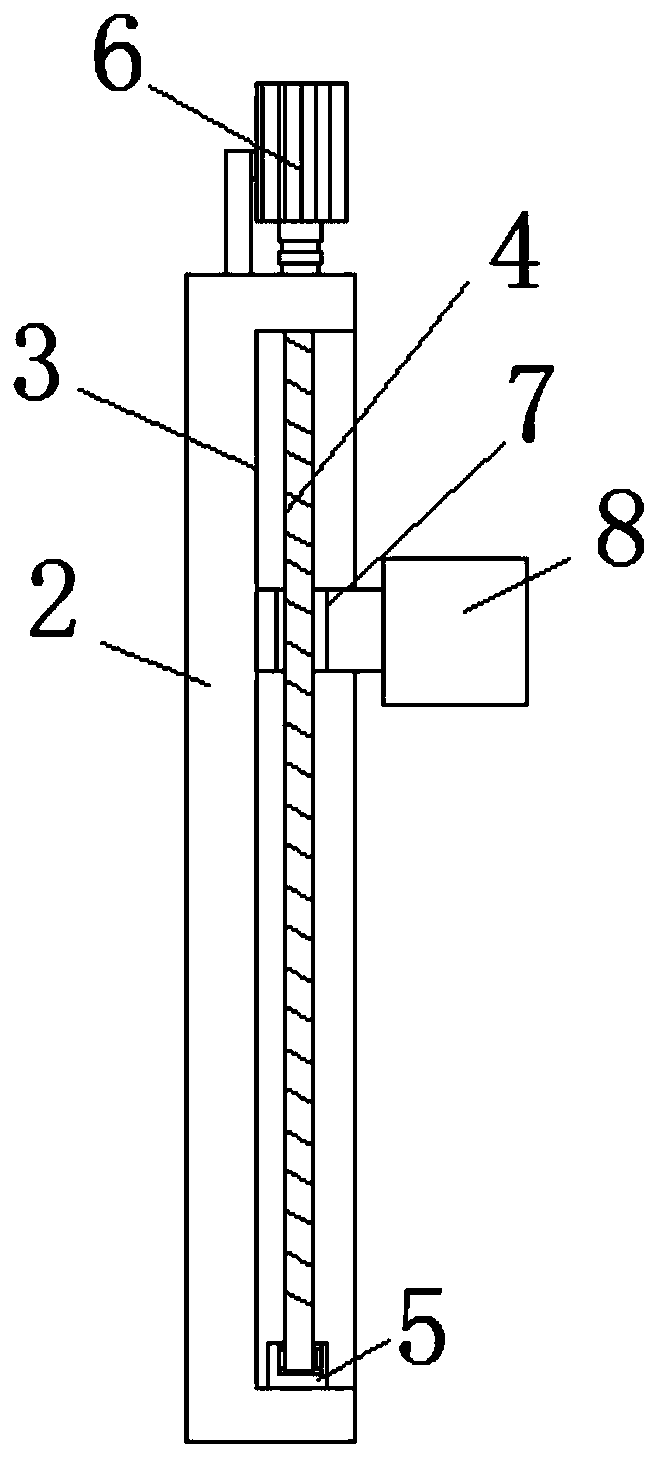

[0022] see Figure 1-4 , the present embodiment provides a kind of transfer vehicle convenient for loading and unloading goods used in intelligent manufacturing industry, comprising a vehicle body 1, a shelf 2 is welded on the top side of the vehicle body 1, and a moving slot 3 is provided on one side of the shelf 2, The inner wall of the moving groove 3 is provided with a screw mandrel 4, and the top of the screw mandrel 4 runs through the shelf 2 and extends to the outside of the shelf 2. The top of the shelf 2 is fixedly equipped with a servo motor 6, and the output shaft of the servo motor 6 is connected to the screw mandrel. 4 Fixed connection, the surface of the screw rod 4 is threadedly connected with a moving threaded slider 7, one side of the threaded slider 7 is welded with a mounting block 8, and one side of the mounting block 8 is fixedly connected with a first hinged seat 9, the first hinged seat The top of 9 is hinged with a first hydraulic cylinder 10, the top o...

Embodiment 2

[0025] see Figure 1-4 , on the basis of embodiment 1, a further improvement has been made: the bottom of the inner wall of the moving groove 3 is fixedly connected with a rotating seat 5, the inner wall of the rotating seat 5 is provided with a bearing, the screw rod 4 is socketed with the inner edge of the bearing, and by setting the rotating seat 5. The position of the screw rod 4 can be limited to prevent misalignment during the rotation process, and the bearing can make the rotation of the screw rod 4 smoother while limiting the position of the screw rod 4, reducing the number of screw rods 4. Friction between the rotating seat 5, the top of the shelf 2 is provided with a turning hole, the turning hole communicates with the moving groove 3, and the screw mandrel 4 is rotatably connected with the turning hole through the bearing, which reduces the friction between the screw mandrel 4 and the shelf 2. Friction reduces the load on the servo motor 6.

[0026] Wherein, the st...

Embodiment 3

[0028]see image 3 , made a further improvement on the basis of Embodiment 1: the top of the car body 1 is provided with a partition plate 23 between the shelf 2 and the placement plate 14, by setting the partition plate 23, some smaller volume The bulk goods are placed between the partition plates 23 to prevent them from rolling down. The bottom of the car body 1 is fixedly connected with a driving wheel 19, and the bottom of the car body 1 is fixedly connected with a threaded pipe 20, and the inner wall of the threaded pipe 20 is threadedly connected with a threaded pipe. Rod 21, the bottom of threaded rod 21 is fixedly connected with spacer 22, in the process of loading and unloading, threaded rod 21 can be rotated, so that spacer 22 moves downward and contacts with the ground, plays a supporting role, prevents vehicle body 1 from loading and unloading goods movement occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com