Seamlessly spliced display

A technology of seamless splicing and display, applied in the directions of instruments, optics, optical components, etc., can solve the problems of affecting the display effect and easily reflecting external light, and achieve the effect of solving the problem of reflection and solving the problem of screen stretching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

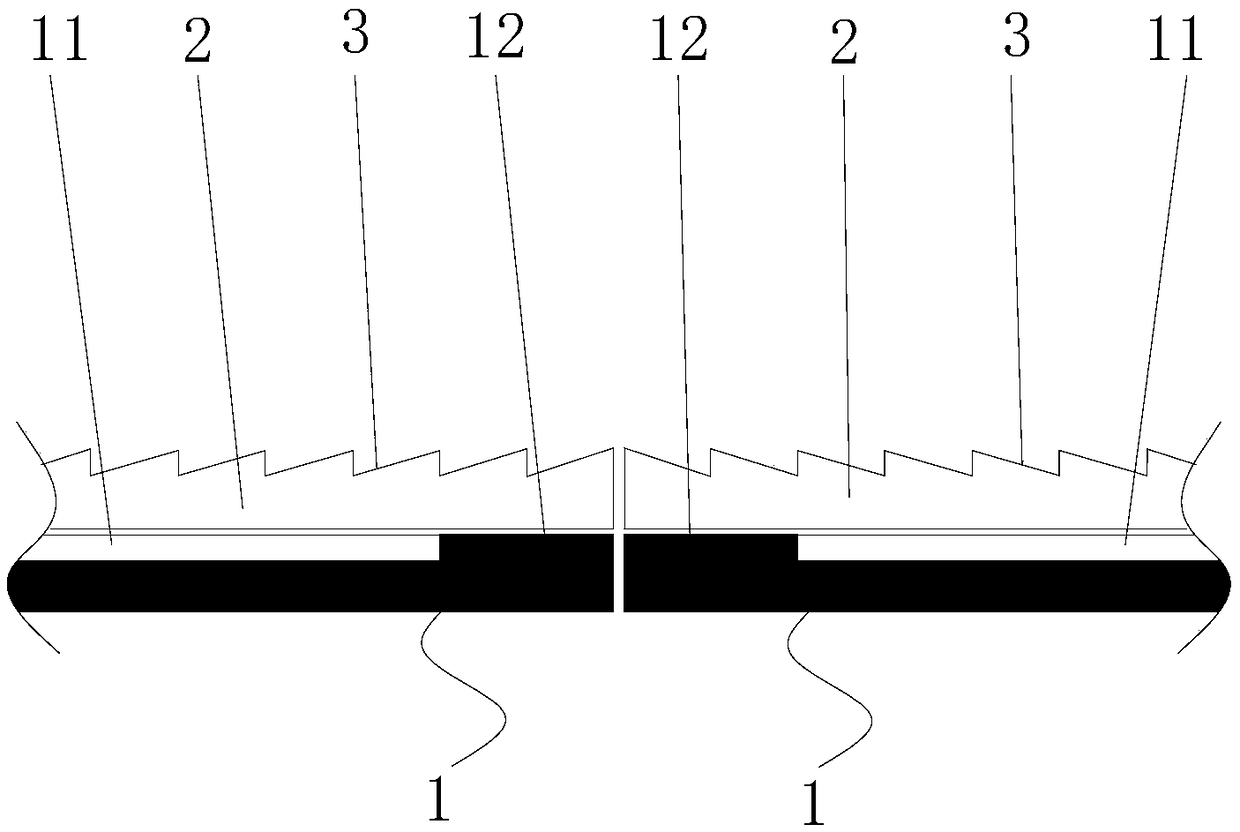

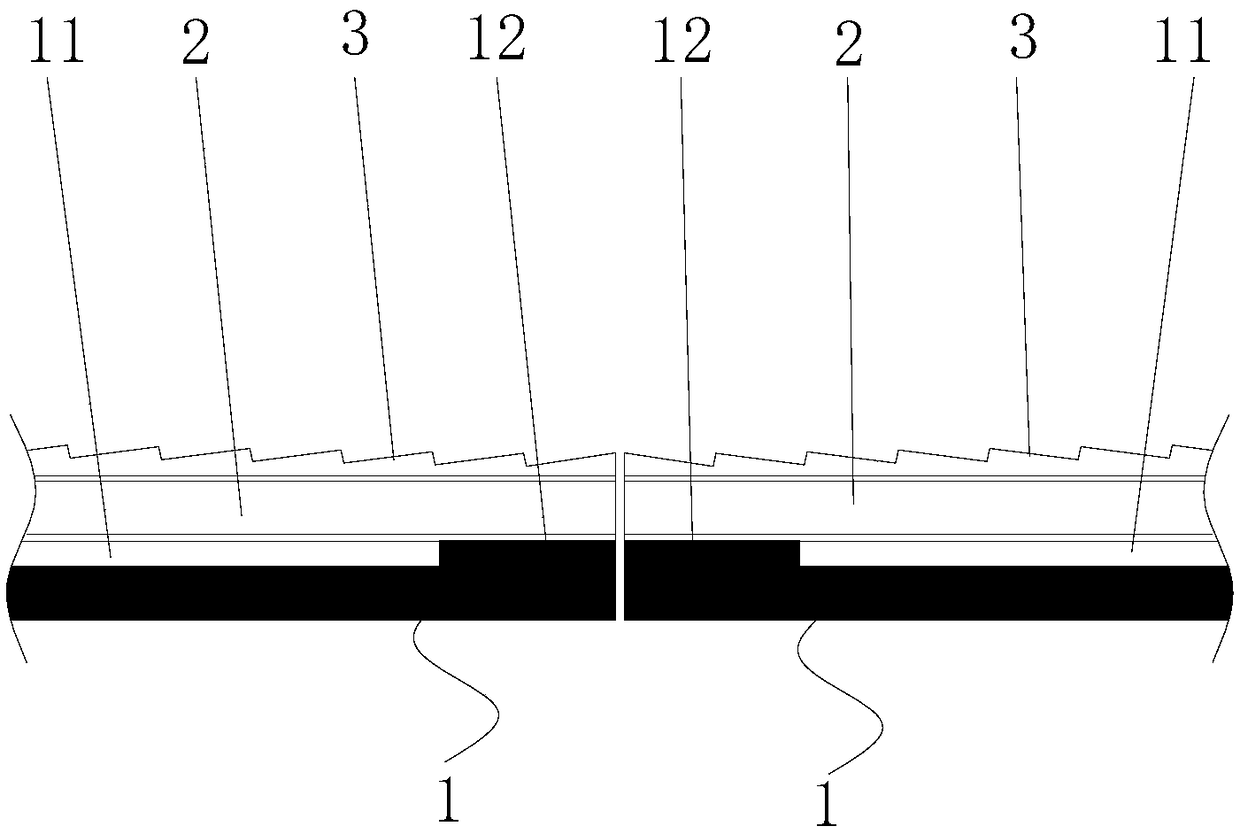

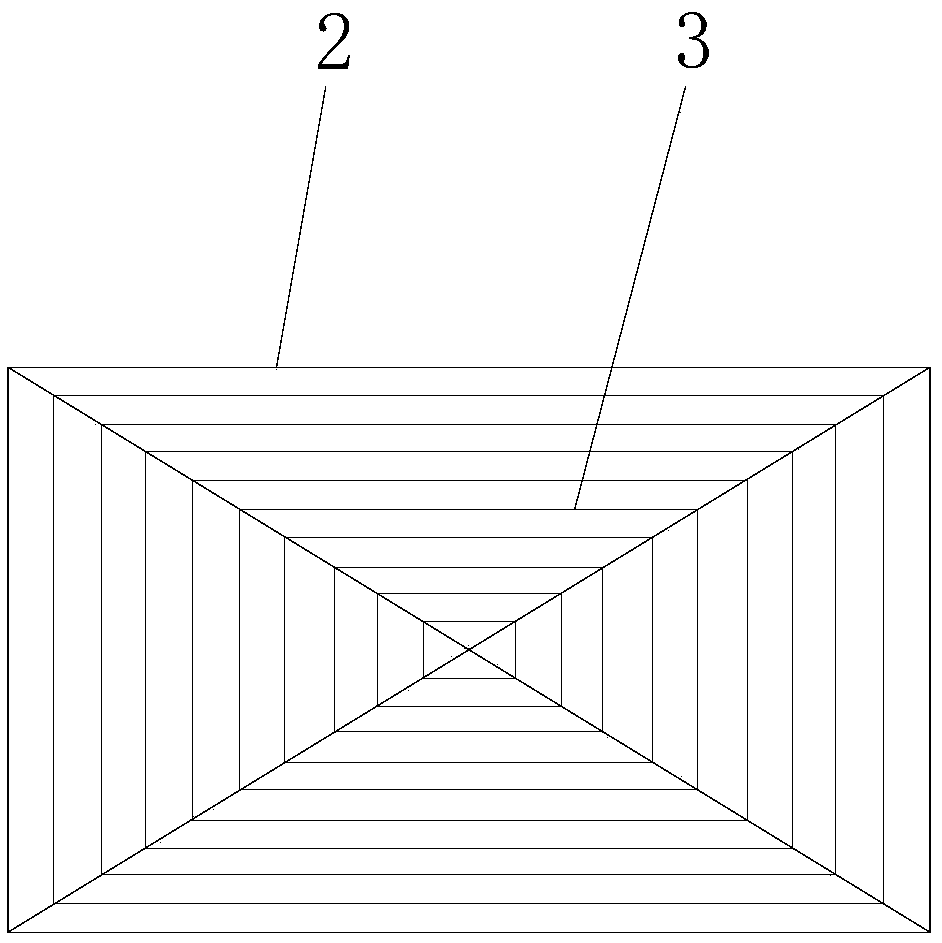

[0021] as attached Figure 1-3 As shown in one of them, the present invention includes a display screen 1 spliced with each other. The front of the display screen 1 is provided with a light-transmitting plate 2 covering the display area 11 and the frame 12 of the display screen 1. The front surface of the light-transmitting plate 2 It is the light-emitting surface, and the micro-prism structure 3 covering the entire light-emitting surface is provided on the light-emitting surface. The center extends to each frame 12 of the screen, and the prism strips extending along each frame 12 are respectively parallel to the frame 12 in the extending direction, and the prism strips in two adjacent extending directions are connected to each other, and each direction starts from the center of the light-transmitting plate The included angle between the slope of the prism strip and the horizontal plane towards the frame of the screen changes gradually so that the display picture in the disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com