Device of using implant anchorage to distalize maxillary molar

A technology of remote displacement and implantation nails, which is applied in dental implantation, dentistry, dental prosthesis, etc., can solve the problems of difficult traction force, inconvenient stainless steel wire, and difficult implantation of implants, etc., and achieves easy operation and safety. High, firm mucosal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

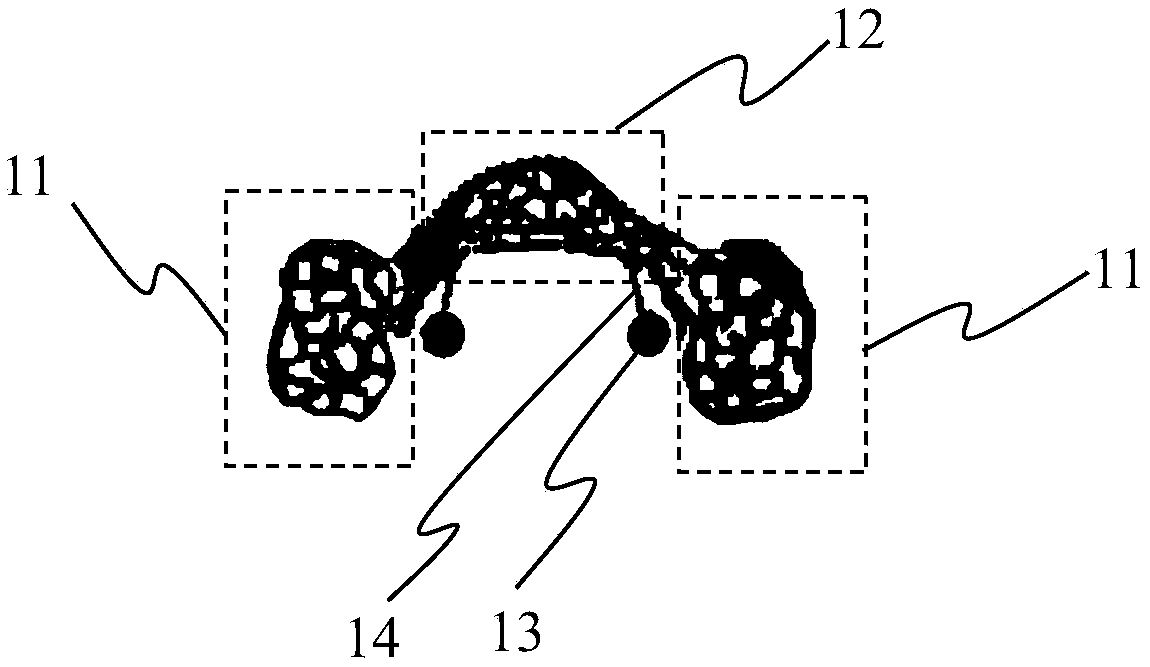

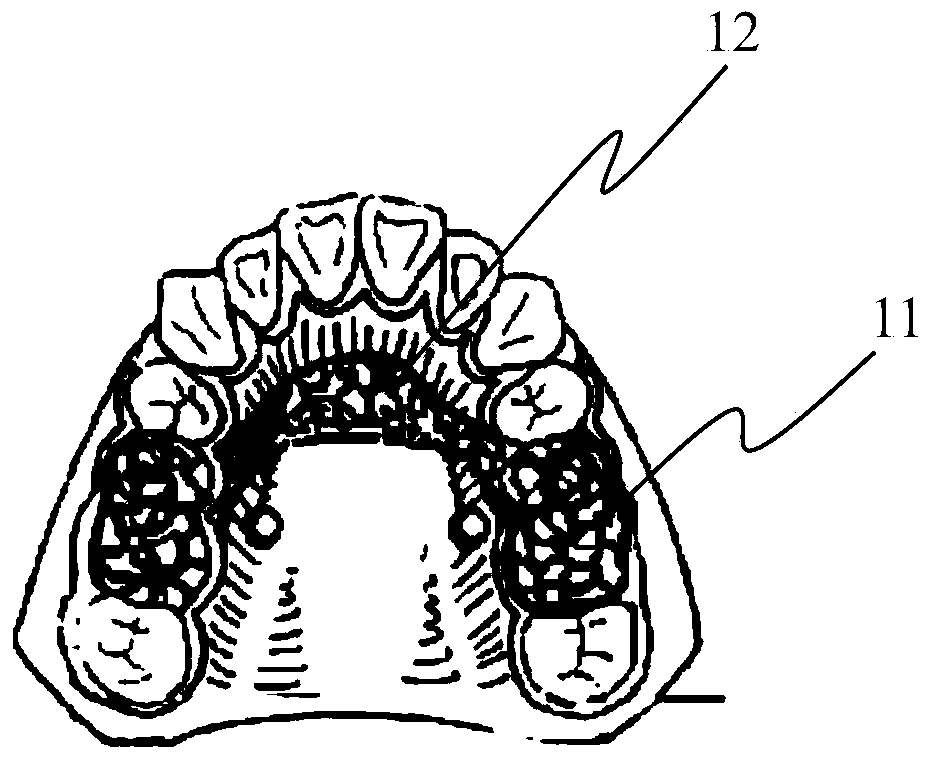

[0027] Such as figure 1 As shown, the device for using the implant anchorage to move the maxillary molars away includes: a cast bracket with a fixed part 11 on both sides of the tooth surface and a palatal connector 12 arranged between the two fixed parts on the tooth surface; an implant anchorage 13 ; The traction hook 14 and the hook of the palatal connector.

[0028] The casting bracket has two tooth surface fixing parts 11 and a palatal connecting body 12 arranged between the two tooth surface fixing parts 11 . In the initial state, the curvature of the palatal connecting body 12 is forward and fits the palatal mucosa. The area of the tooth surface fixing portion 11 can cover the occlusal surfaces of two or more posterior teeth.

[0029] Implant anchorage 13, fixed on the upper jaw. The nail head of the implant anchorage 13 is flush with the furcation of the maxillary molars. In the specific operation, the position of the nail head is usually based on empirical value...

Embodiment 2

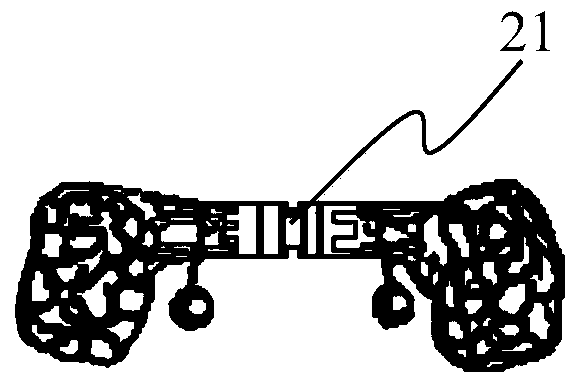

[0034] The overall structure of the device for moving maxillary molars away using implant anchorage in this embodiment is the same as that in Embodiment 1. The difference is that a helical expander is placed in the middle of the palatal connector. details as follows:

[0035] The spiral expander 21, the palatal connector has two left and right sub-palatal connectors, and the helical expander is arranged between the two sub-palatal connectors. Due to the presence of the spiral expander 21, the palatal connector is divided into two sub-palatal connectors 22 on the left and right.

[0036] When it is necessary to move the molars more than 2mm distally, because the upper posterior teeth on both sides extend backward and outward in a "eight" shape, a spiral arch expansion device 21 (Screw arch expansion device) is added at the connection part to expand the arch to both sides Cooperate with the long-distance molar push and move away, so that the molars are always moved away from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com