Pipe coil skid and method of use

A technology of pipe rolls and pipes, applied in this field, can solve the problems of extra equipment and human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

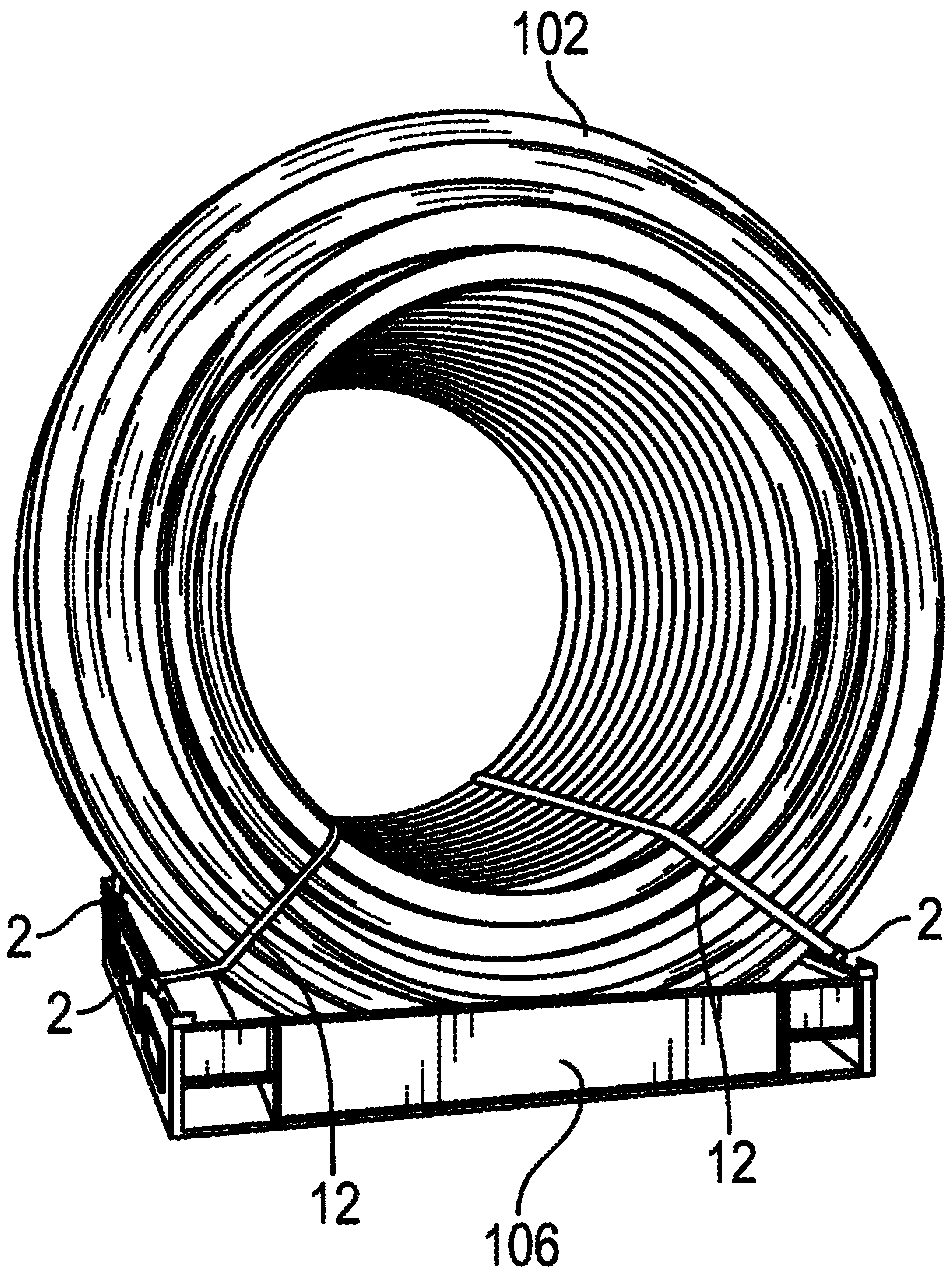

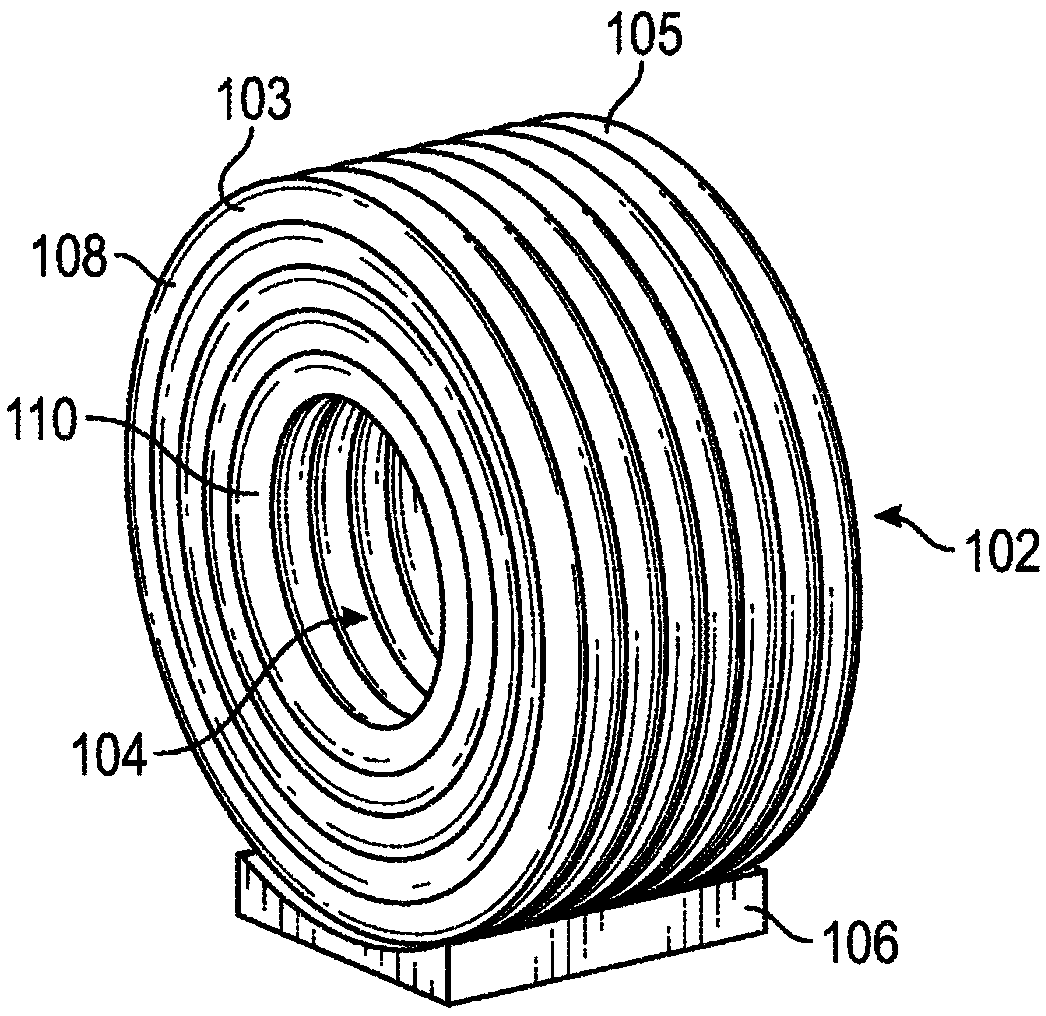

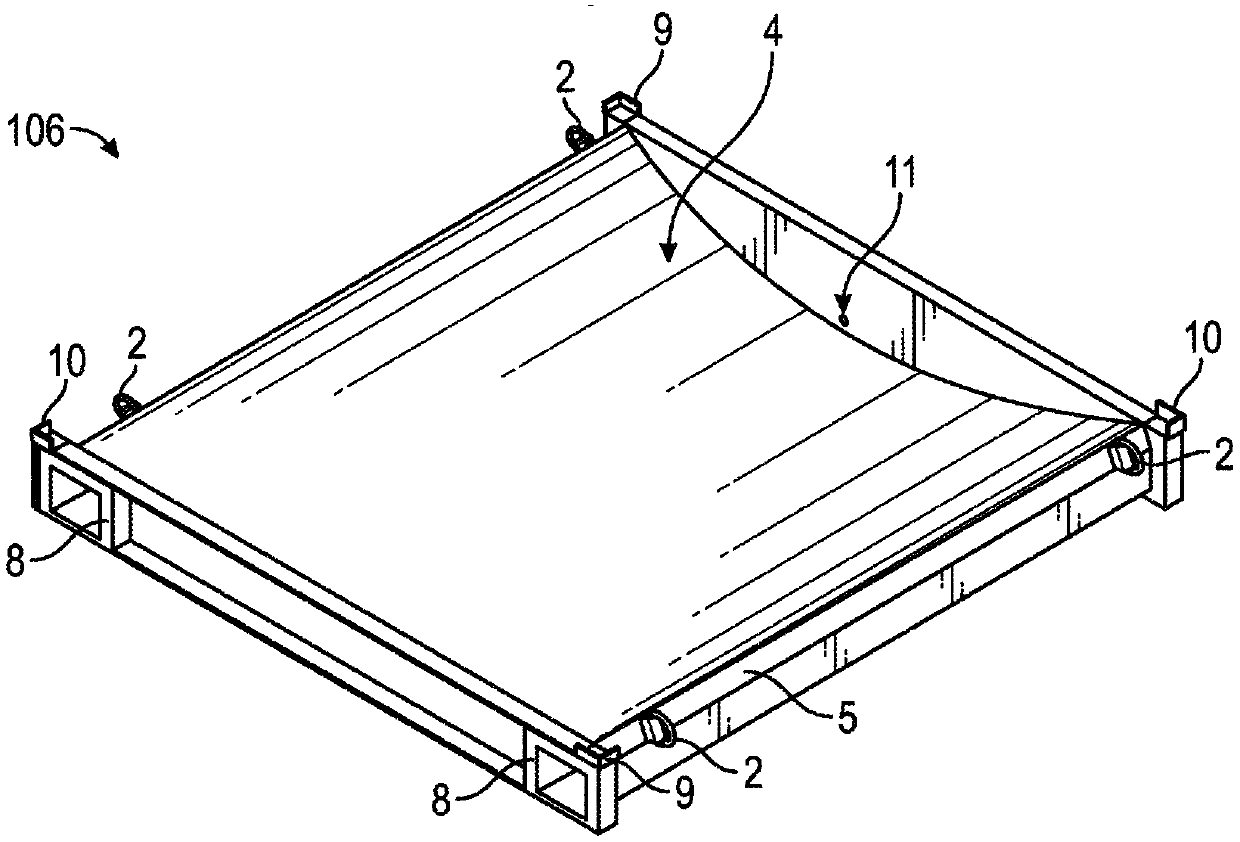

[0023] Embodiments of the present disclosure generally relate to a pipe roll slider for transporting, storing, and / or deploying a pipe roll. The tubing roll may be self-supporting, for example, using rope or straps to secure the rolls together, or the tubing roll may be supported around a reel (which may be referred to as a tubing spool).

[0024] Embodiments of the present disclosure will be described below with reference to the drawings. In one aspect, embodiments disclosed herein relate to embodiments for various sizes of tubing roll sliders configured for storing, deploying, or transporting flexible tubing rolls to various locations.

[0025] As used herein, the term "coupled" or "coupled to" may indicate the establishment of a direct or indirect connection, and is not limited to both unless expressly so referenced. The term "set" may refer to one or more items. Wherever possible, similar or identical reference numbers are used in the drawings to identify common or ident...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com