Defrosting method of air source heat pump hot water unit

A technology of air source heat pump and hot water unit, which is applied in the direction of refrigerators, refrigeration components, lighting and heating equipment, etc. It can solve the problems of no-frost defrosting, thin frost defrosting, affecting the heating capacity and service life of the unit, and achieves Accurate defrosting determination and high heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

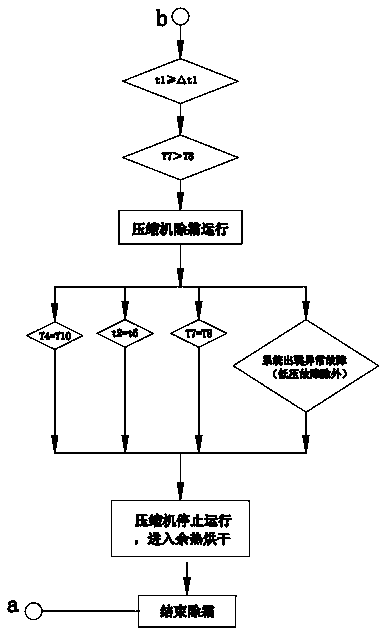

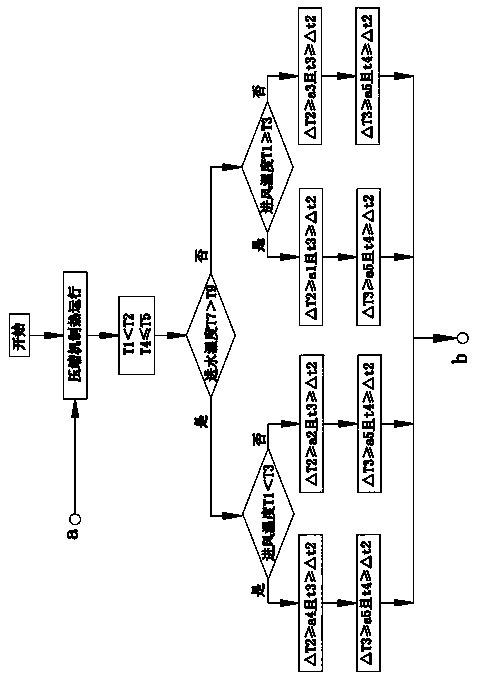

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

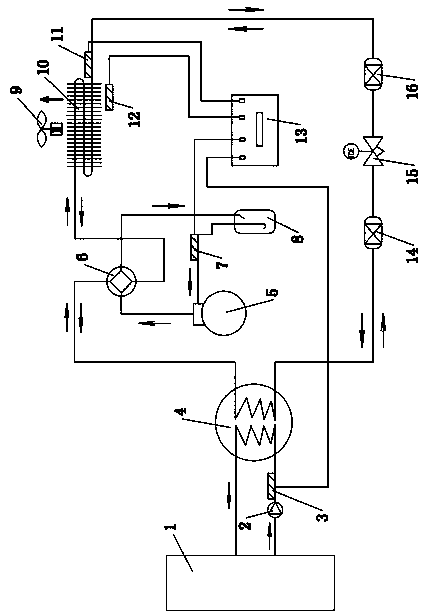

[0034] like Figure 1 to Figure 3 As shown, it is a defrosting method for an air source heat pump water heater unit. The air source heat pump water heater unit includes a water tank 1, a water side condenser 4, a compressor 5, a four-way valve 6, a gas-liquid separator 8, an evaporation Device 10, electrical control system 13, electronic expansion valve 15 and filter.

[0035] A first temperature sensor 12 is installed at the side air inlet of the evaporator 10, a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com