A new type of automatic forming equipment for melons and fruits

An automatic molding and equipment technology, applied in cleaning methods and appliances, chemical instruments and methods, metal processing, etc., can solve problems such as high cost, low ball digging accuracy, complex structure, etc., and achieve high production efficiency and convenient movement And dismantling and maintenance, the effect of high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The melon and fruit automatic forming equipment of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

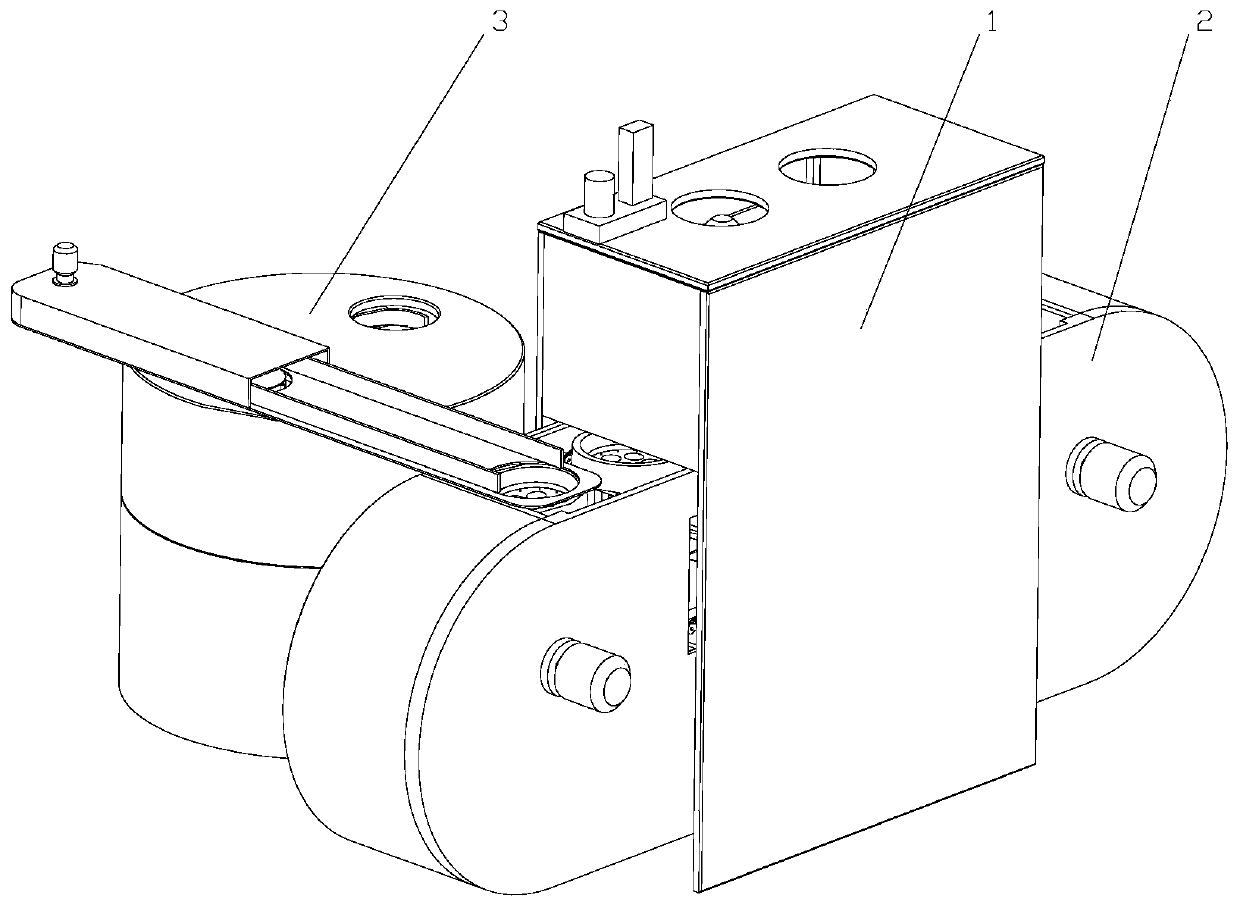

[0027] Figure 1 to Figure 9 It shows a schematic diagram of each device of the melon and fruit automatic molding equipment according to the present invention. Such as figure 1 As shown, the melon and fruit automatic forming equipment according to the present invention includes a pulp forming device 1 , a material conveying device 22 and a pulp slicing device 3 .

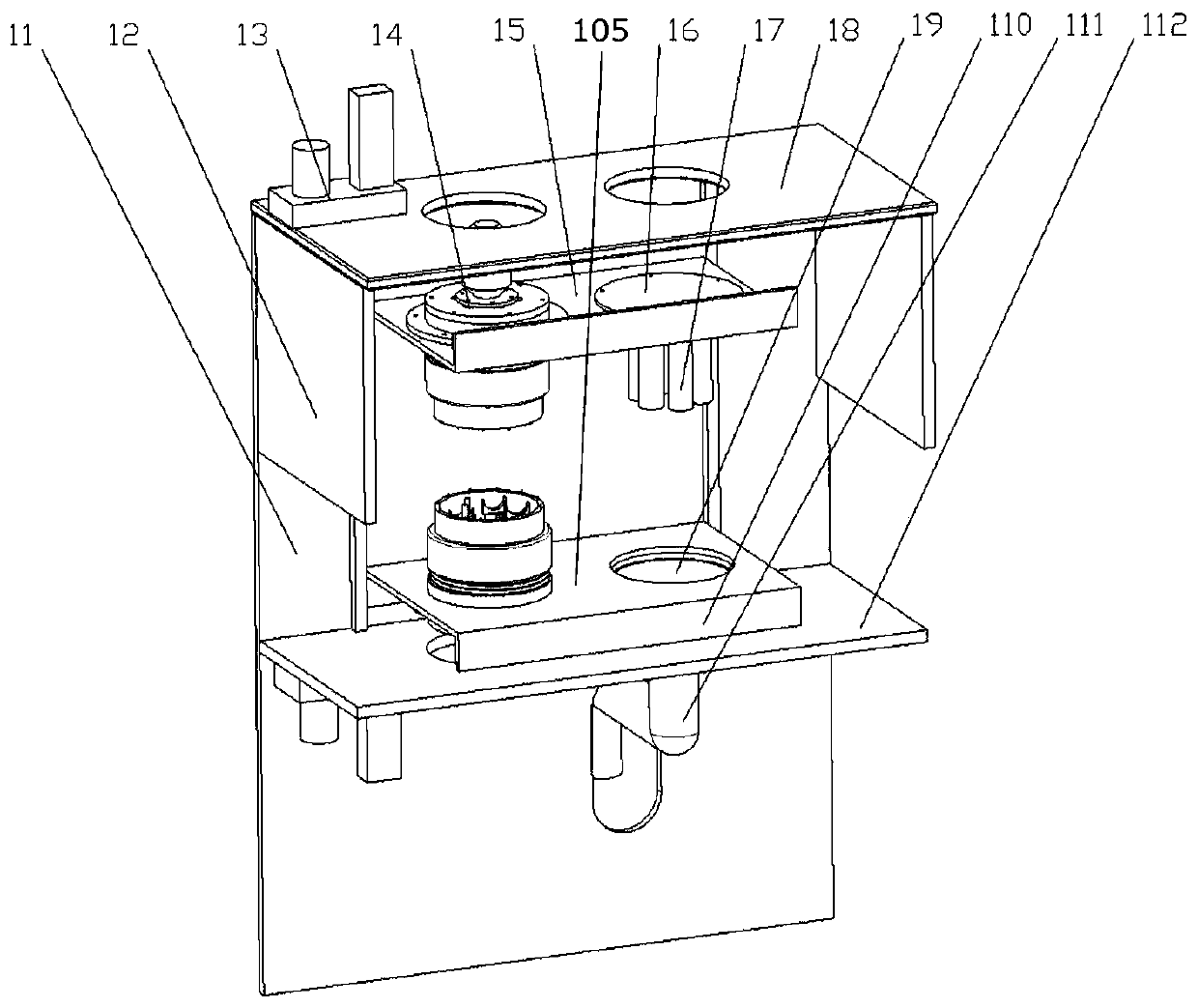

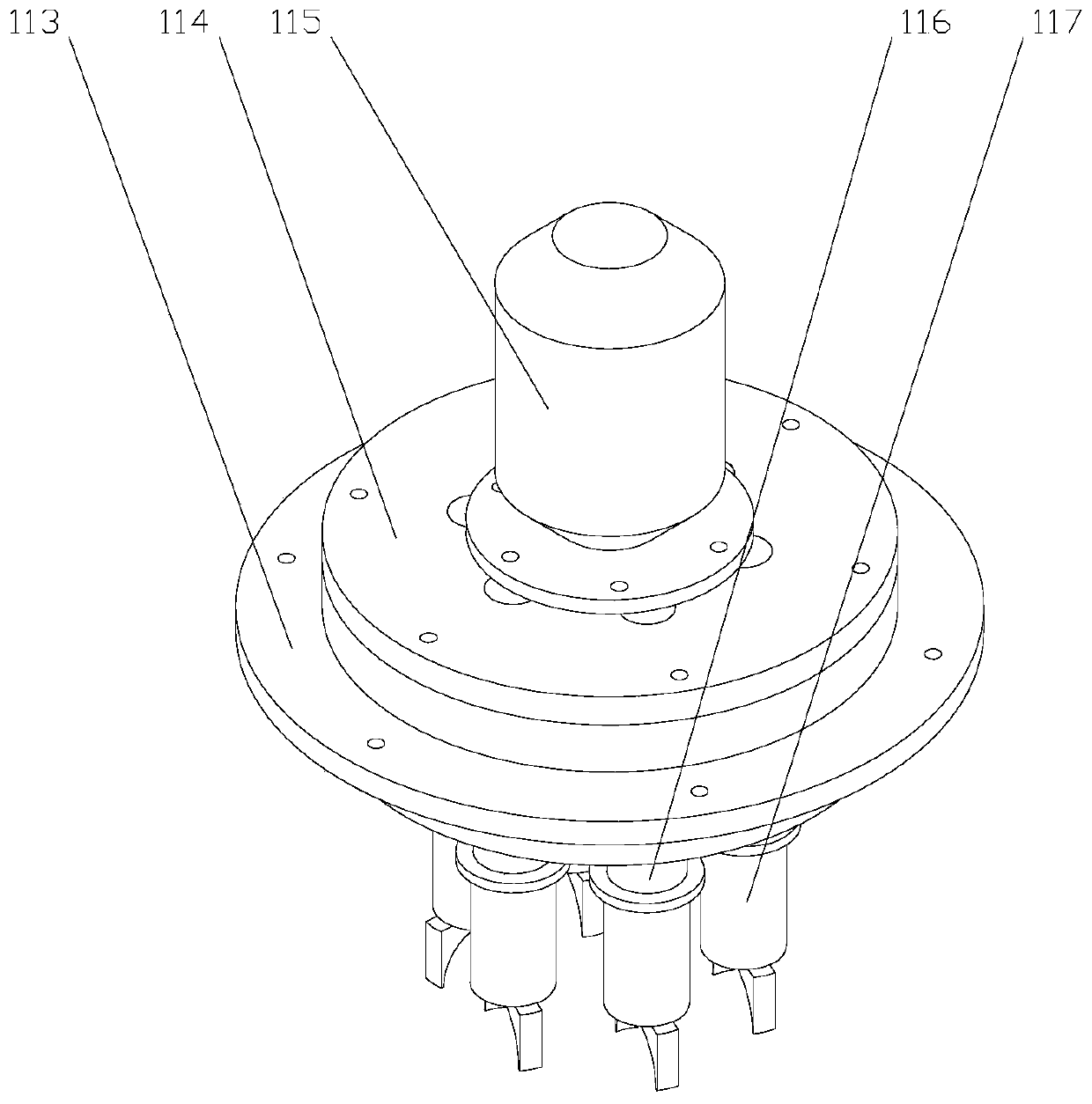

[0028] Such as figure 2 As shown, the pulp forming device 1 includes a large side plate 11, a small side plate 12, an electric cylinder 13, an integrated multi-turn tool part 14, an upper sliding bracket 15, a lower sliding bracket 105, a fixed end cover 16, a push rod 17, and a top plate 18 , guide rail 19, funnel 110, special-shaped pipeline 111 and fixed plate 112. The electric cylinder 13 is connected and fixed on the top pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com