Traction film-pulling compensation detection device and method

A detection device and detection method technology, which is applied in the direction of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of excessive punching size deviation, punching position deviation, large size deviation, etc., to avoid cutting errors or Cut bad, stable control, simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

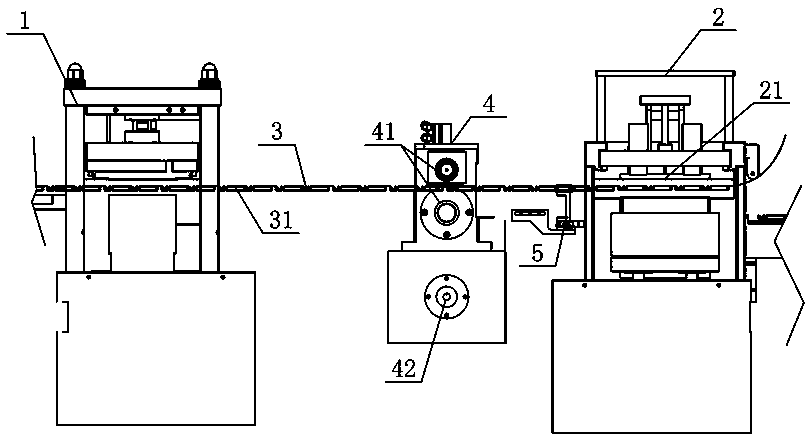

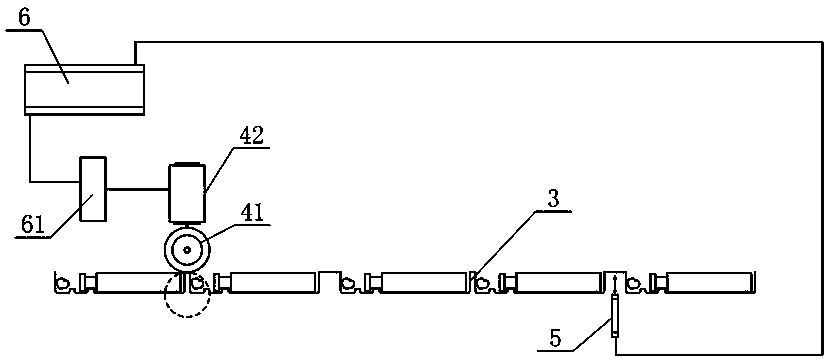

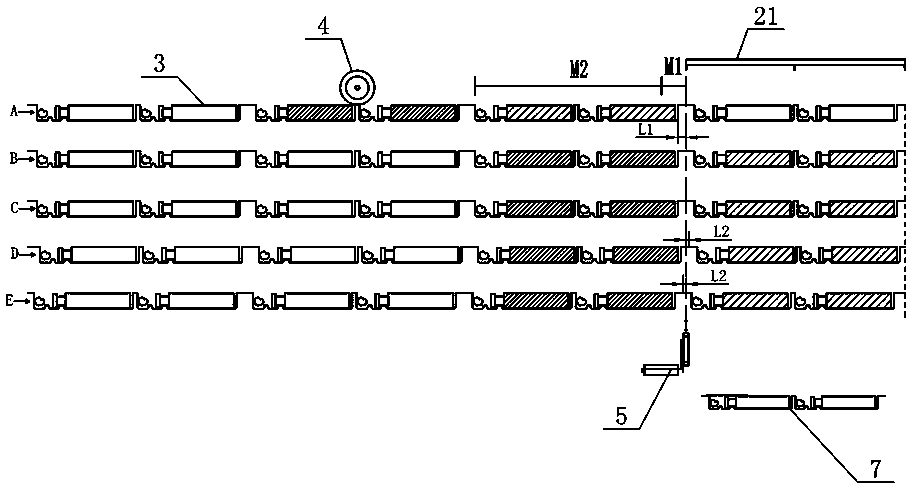

[0030] like figure 1 and figure 2 As shown, the pulling film compensation detection device of this embodiment includes a pulling mechanism 4 arranged between the laminating machine 1 and the punching machine 2 for pulling the PVC forming film 3, and a pulling mechanism 4 arranged between the pulling mechanism 4 and the punching machine. 2 is used to sense the detection piece 5 on the edge of the blister 31 on the PVC forming film 3, the traction mechanism 4 is connected with a PLC control module 6 for controlling its traction stroke, and the PLC control module 6 receives the detection piece 5 (the detection piece 5 is set as Photoelectric detection device) induction information. In this structure, the traction mechanism 4 is arranged between the laminating machine 1 and the punching machine 2. The traction mechanism 4 is used to pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com