A shaft end surface printing mechanism and its use method

A technology of printing mechanism and shaft end face, which is used in typewriters, printing devices, printing and other directions, can solve problems such as the inability to effectively adjust the distance between the print head and the shaft end face, the inability to accurately position the marking machine, and the inability to fix shaft parts, etc. Achieve the effect of solving the inability to efficiently and accurately print, high practicability and versatility, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

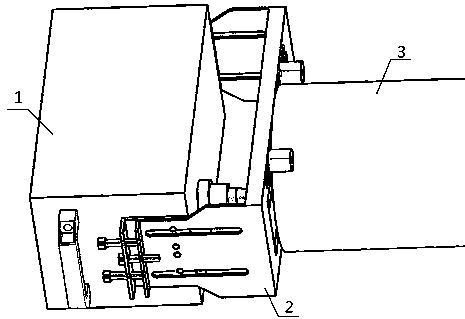

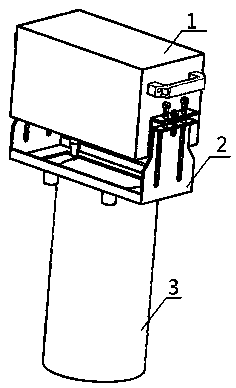

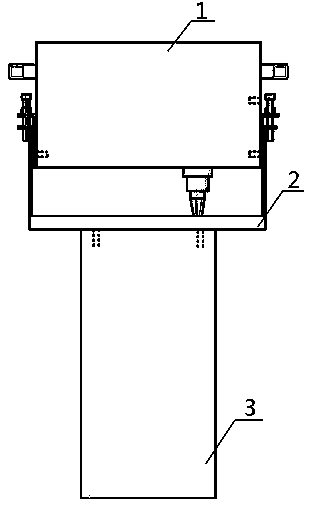

[0024] The shaft end surface printing mechanism includes a printing device 1 and a supporting device 2, the printing device 1 can be detachably connected to the supporting device 2, the supporting device 2 can be supported on the shaft part 3, and the printing head of the printing device 1 passes through the supporting device 2. Print the end face of the shaft part 3.

Embodiment 2

[0026] The printing device 1 includes a rectangular housing 1-1. The front side of the rectangular housing 1-1 is in the form of an opening, and the other sides are assembled from plates. The plates can be stainless steel plates, wood plates, etc., and the plates can be transparent. , can also be opaque, and a drive assembly is arranged inside the rectangular housing 1-1.

[0027] The drive assembly includes a carrier plate 1-2, which is transversely connected to the middle of the left and right side panels of the rectangular housing 1-1, and the carrier plate 1-2 is provided with a continuous and uninterrupted arc-shaped guide rail 1-2 from left to right. 3. On the left side of the carrier board 1-2 and at the rear of the arc guide rail 1-3, there is a carrier board through hole, and on the right side of the carrier board 1-2 and at the rear of the arc guide rail 1-3, there is a carrier board through hole. Plate pin, the drive shaft of the transversely moving drive motor 1-4 ...

Embodiment 3

[0036] The support device 2 includes a main board 2-1, a side board 2-2 is respectively connected to both sides of the main board 2-1, and the middle part of the main board 2-1 is provided with a rectangular through slot, and the printing head of the printing device 1 can pass through the rectangular through slot , a slender elliptical groove is arranged parallel to the top of the rectangular through trough, and two sliding bolts are slidingly clamped in the slender elliptical groove, and the screw part of the sliding bolt passes through the slender elliptical groove and is connected with the smooth pressure column nut 2-3, each The rear ends of each side plate 2-2 are all vertically connected with flaps, and each flap is connected with a vertical corner plate 2-4, and the vertical corner plate 2-4 is composed of a front riser and a rear riser, wherein the flaps The middle part of the vertical gusset is provided with a middle screw hole, and the middle part of the front vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com