An imitation form garlic root cutting machine and its root cutting method

A technology for cutting roots and garlic, applied in the fields of application, food science, food processing, etc., can solve the problems of high price, reduce the service life of the machine, time-consuming and high-efficiency workers, and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

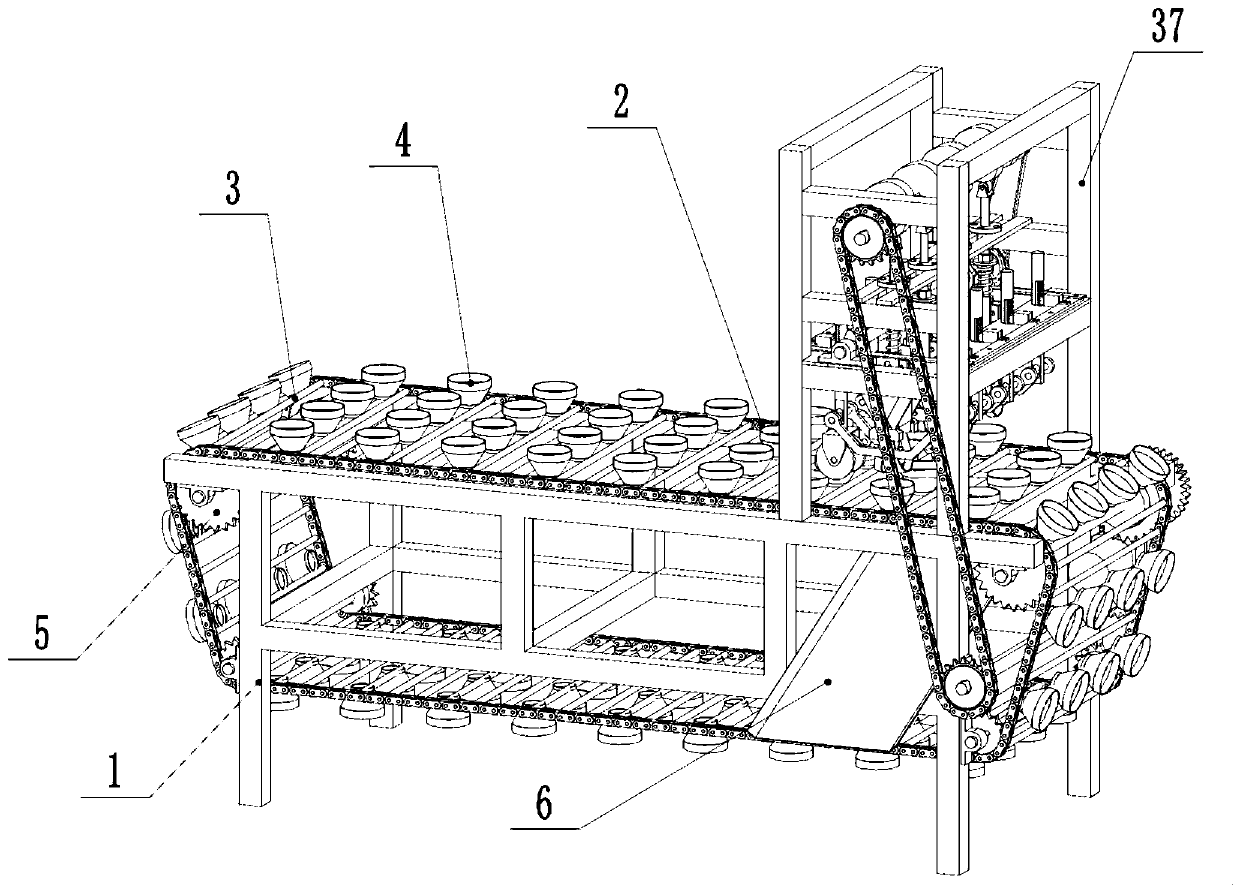

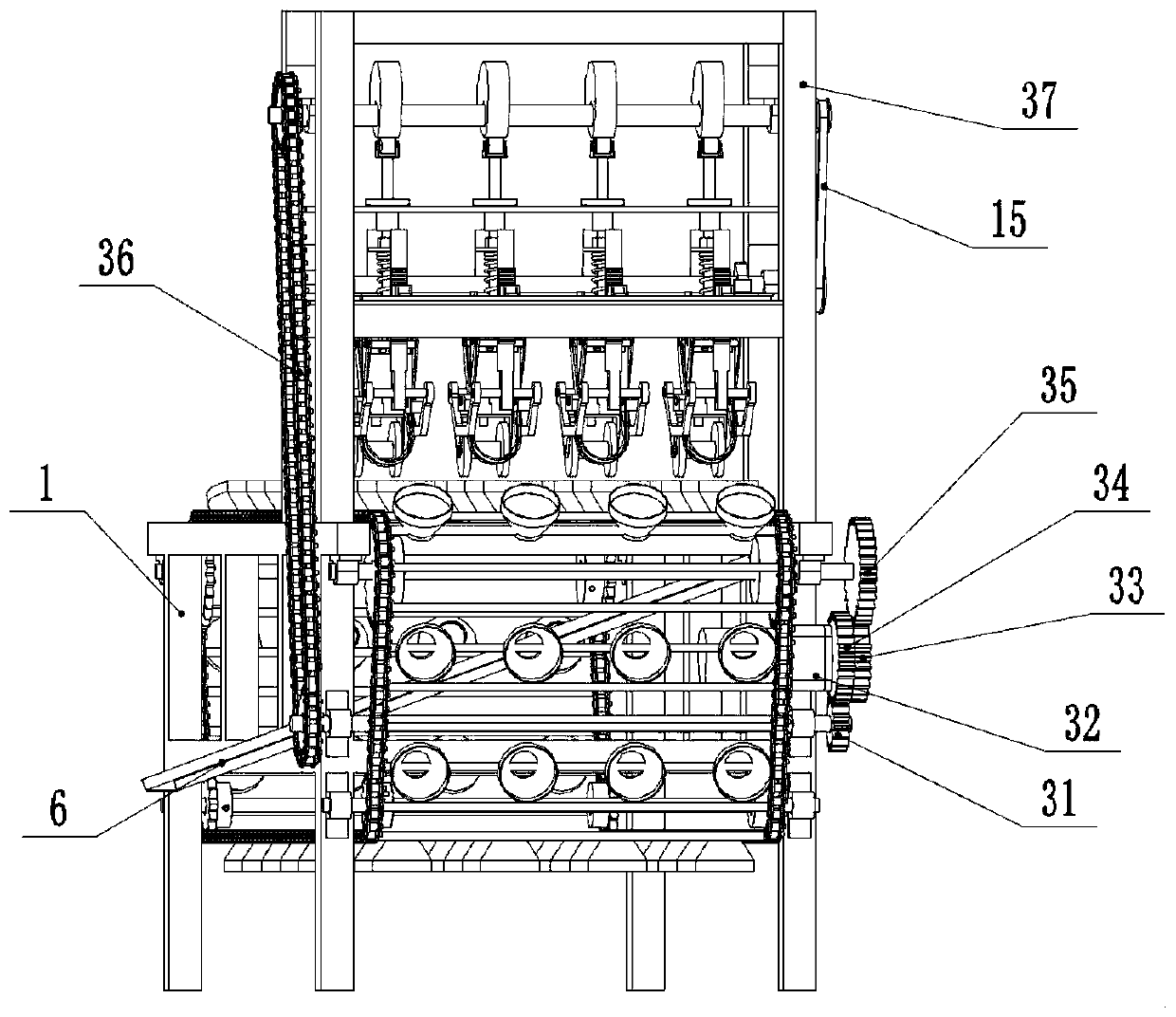

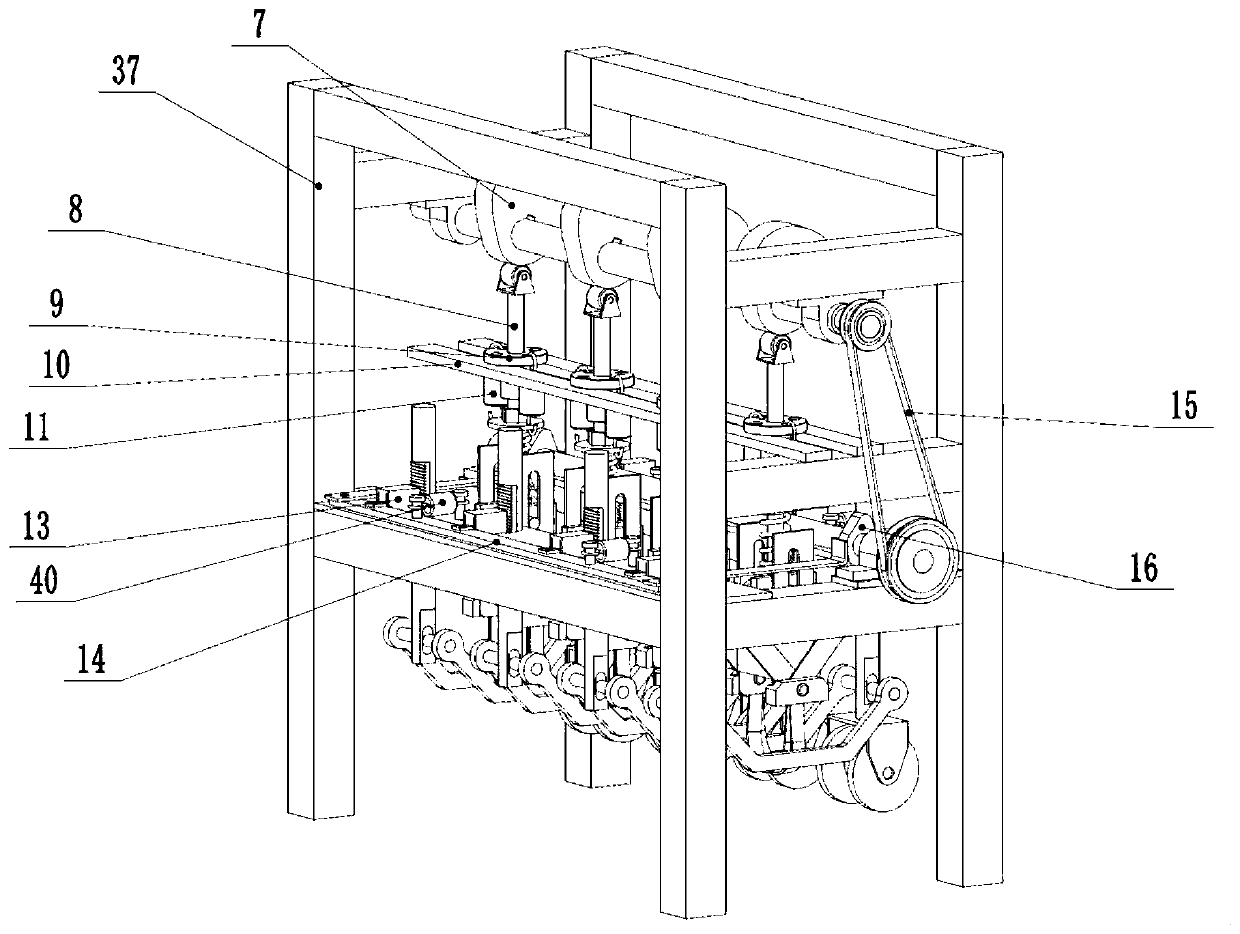

[0041] Such as figure 1 with 2 Shown, a kind of imitation form garlic root cutting machine comprises frame 1, transmission mechanism, profiling root cutting device, waste material slideway 6 and intermittent combined drive mechanism. The transmission mechanism includes a top conveying shaft, a bottom conveying shaft, a chain drive assembly and a discharge piece. Two top conveying shafts arranged at equal heights are respectively supported at the two ends of the top of the frame. Both bottom conveying shafts are supported on the bottom of the frame and are lower than the top conveying shafts. The chain drive assembly includes a transmission sprocket 5 and a transmission chain 2 . Four transmission sprockets 5 are respectively fixed with two top conveying shafts and two bottom conveying shafts. Four transmission sprockets 5 are connected by transmission chain 2 . There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com