Arc Grinding Composite Tool Electrode

A composite tool and composite electrode technology, which is applied in the field of composite tool electrodes, can solve the problems of poor surface quality of workpieces, inability to compensate in time, inability to process electrodes and abrasive loss of non-rotating parts, and achieve economical material erosion finishing, Effects of improving quality and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

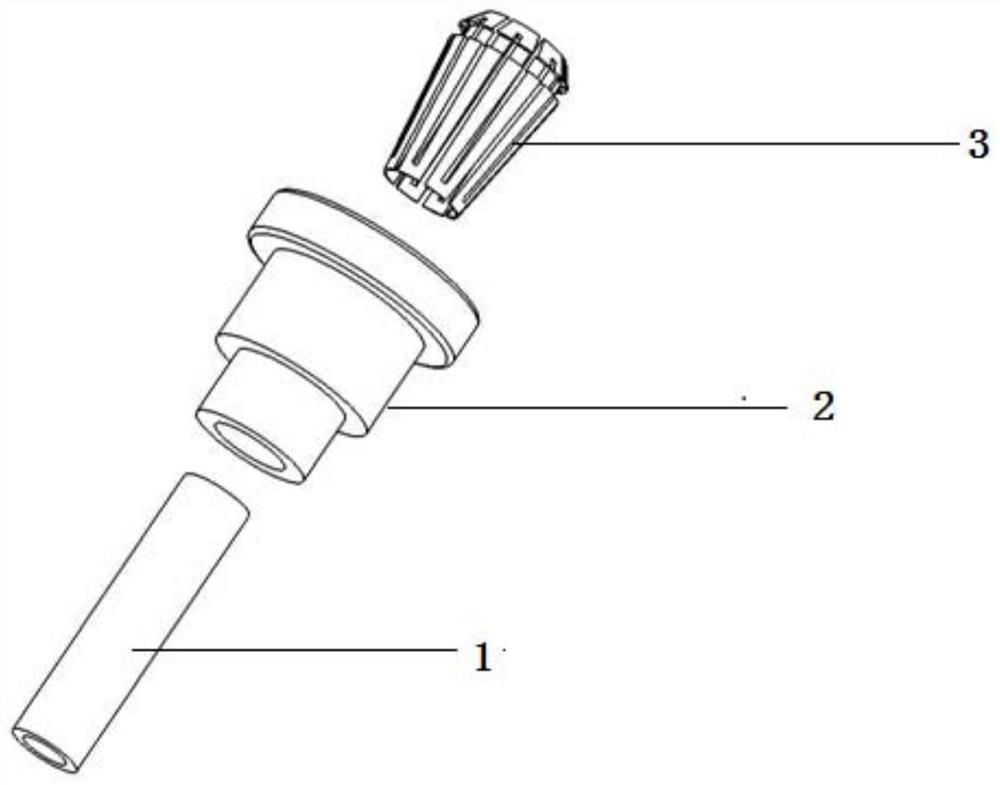

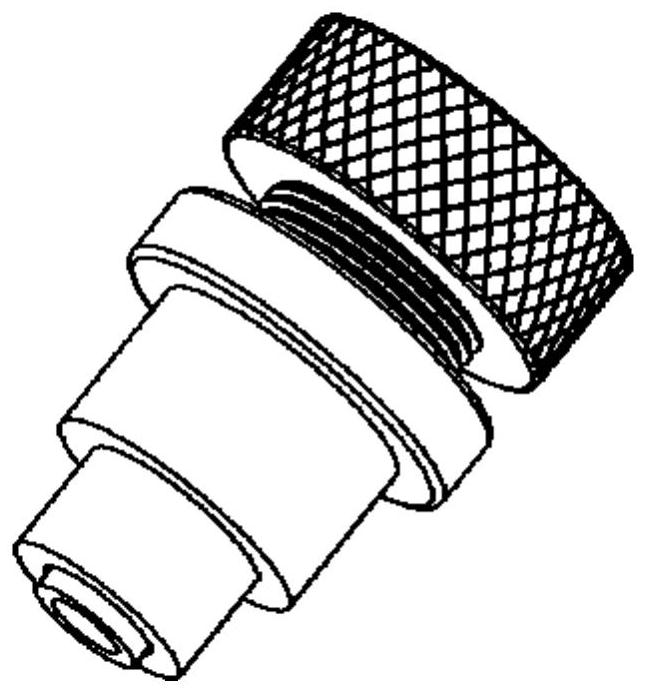

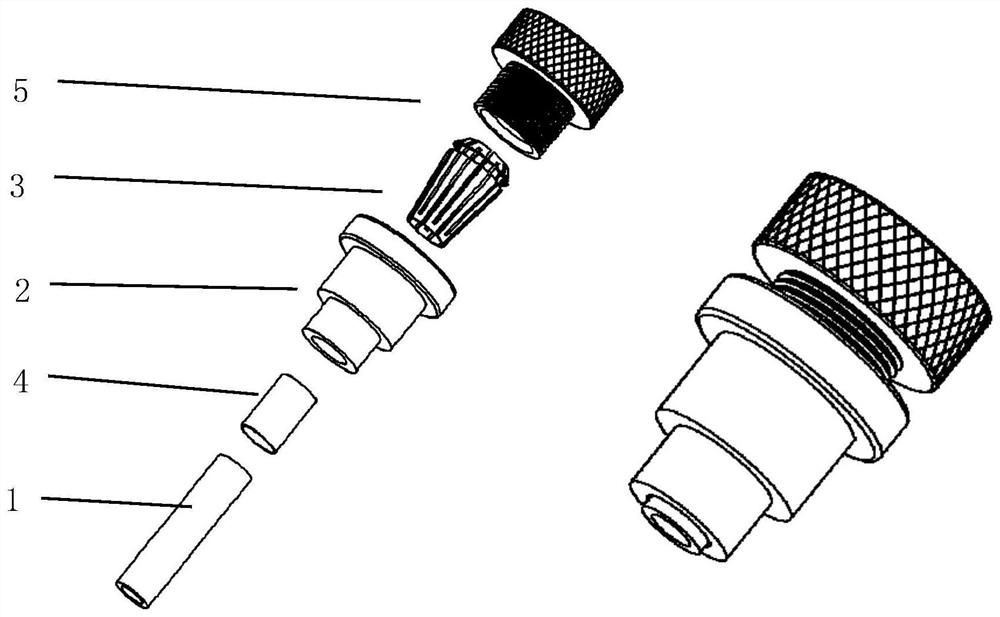

[0042] combined with Figure 4The working process of the present invention is explained as follows: during arc grinding, the compound tool electrode is connected to the machine tool spindle 6, and the workpiece 7 is fixed on the machine tool workbench as the machine tool spindle 6 rotates at high speed. The composite electrode is connected to the positive pole or the negative pole of the power supply, and the workpiece 7 is connected to the negative pole or the positive pole of the power supply. The distance between the ring electrode 2 and the workpiece 7 is adjusted to a suitable discharge gap through the servo movement of the machine tool. The power supply, electrodes, discharge gap and workpiece form a current loop, and the discharge power supply provides pulsed DC. The working fluid continuously flushes the machining surface of the workpiece 7 through the flushing hole of the electrode of the composite tool to realize hydrodynamic arc breaking and flush away the erosion p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| material removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com