A fuel cell membrane-electrode interface structure characterization sample processing method

A fuel cell membrane and electrode interface technology, which is applied to fuel cells, circuits, analytical materials, etc., can solve the problems of difficult section imaging, the inability to neatly break the plane, and the difficulty in grasping the position of the break, so as to achieve the effect of a simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

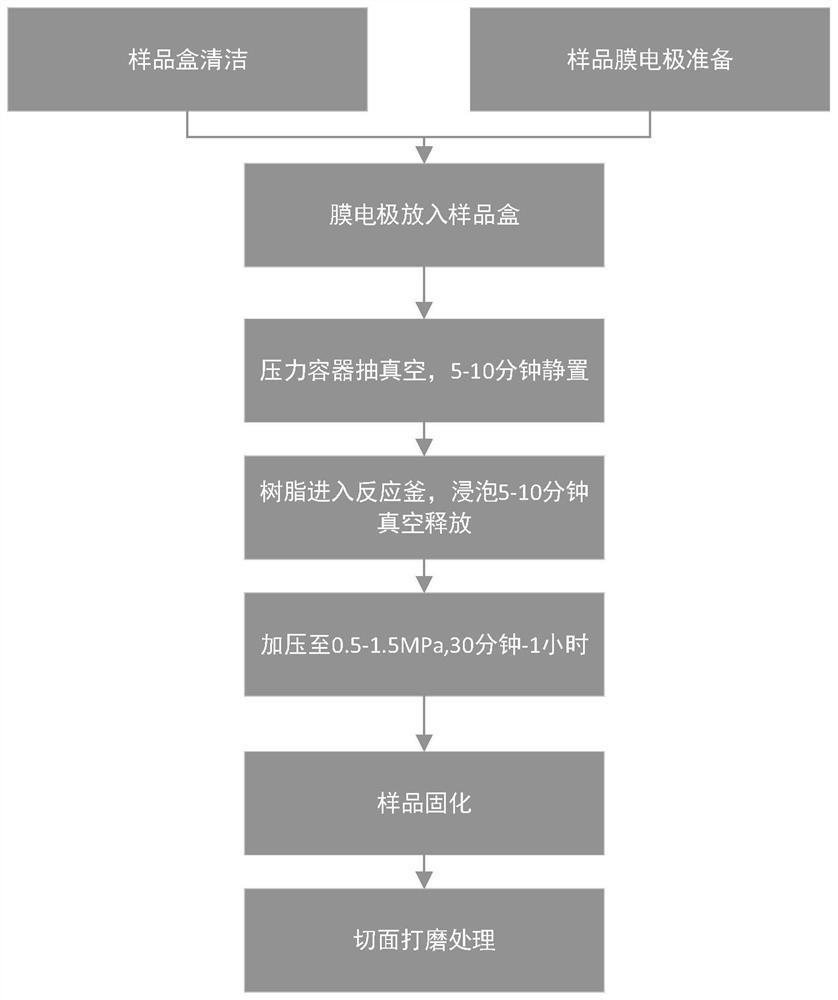

[0026] A fuel cell membrane electrode interface structure characterization sample processing method, comprising the following steps:

[0027] (1) Place the membrane electrode sample in a sealable sample box; The membrane electrode sample is a fuel cell membrane electrode, comprising a proton exchange membrane and a catalyst layer and a diffusion layer disposed on both sides thereof.

[0028] (2) The sample box is placed in the reactor, the reactor is sealed, the vacuum is pumped to 1.3Pa absolute pressure, and it is allowed to stand for 8min; the membrane electrode sample, especially the diffusion layer, is generally a porous channel, and under this vacuum, the gas in the porous channel can be extracted.

[0029] (3) The liquid resin is input into the reactor, and the input amount of the liquid resin is to completely immerse the membrane electrode sample in the liquid resin; The liquid resin is an epoxy resin and methanol in accordance with the mass ratio of 1: 6 mixed.

[0030] (...

Embodiment 2

[0034] A fuel cell membrane electrode interface structure characterization sample processing method, comprising the following steps:

[0035] (1) Place the membrane electrode sample in a sealable sample box; The membrane electrode sample is a fuel cell membrane electrode, comprising a proton exchange membrane and a catalyst layer and a diffusion layer disposed on both sides thereof.

[0036] (2) Place the sample box in the reactor, seal the reactor, vacuum to 12Pa absolute pressure, and stand for 5min;

[0037](3) The liquid resin is input into the reactor, and the input amount of the liquid resin is to completely immerse the membrane electrode sample in the liquid resin; The liquid resin is an epoxy resin or phenolic resin and an organic solvent mixed according to a mass ratio of 1: 5. The organic solvent comprises methanol, ethanol or propanol.

[0038] (4) Release the vacuum, pressurize the reactor to 0.5MPa, and keep it for 60min;

[0039] (5) Release the reactor pressure so t...

Embodiment 3

[0042] A fuel cell membrane electrode interface structure characterization sample processing method, comprising the following steps:

[0043] (1) Place the membrane electrode sample in a sealable sample box; The membrane electrode sample is a fuel cell membrane electrode, comprising a proton exchange membrane and a catalyst layer and a diffusion layer disposed on both sides thereof.

[0044] (2) Place the sample cassette in the reactor, seal the reactor, vacuum to 2Pa absolute pressure, and let stand for 10min.

[0045] (3) The liquid resin is input into the reactor, and the input amount of the liquid resin is to completely immerse the membrane electrode sample in the liquid resin; The liquid resin is an epoxy resin or phenolic resin and an organic solvent mixed according to a mass ratio of 1: 10. The organic solvent comprises methanol, ethanol or propanol.

[0046] (4) Release the vacuum, pressurize the reactor to 1.5MPa, and keep it for 30min;

[0047] (5) Release the reactor pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com